Quick-locking fastener unit, combined fastener, tie rod and portal frame

A locking buckle and fast technology, which is applied in the fields of tie rods and door frames, quick locking fastener units, and combined fasteners, can solve the problems of stability damage to the support system, hidden dangers and other problems, and achieves simple structure and convenient processing. , the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

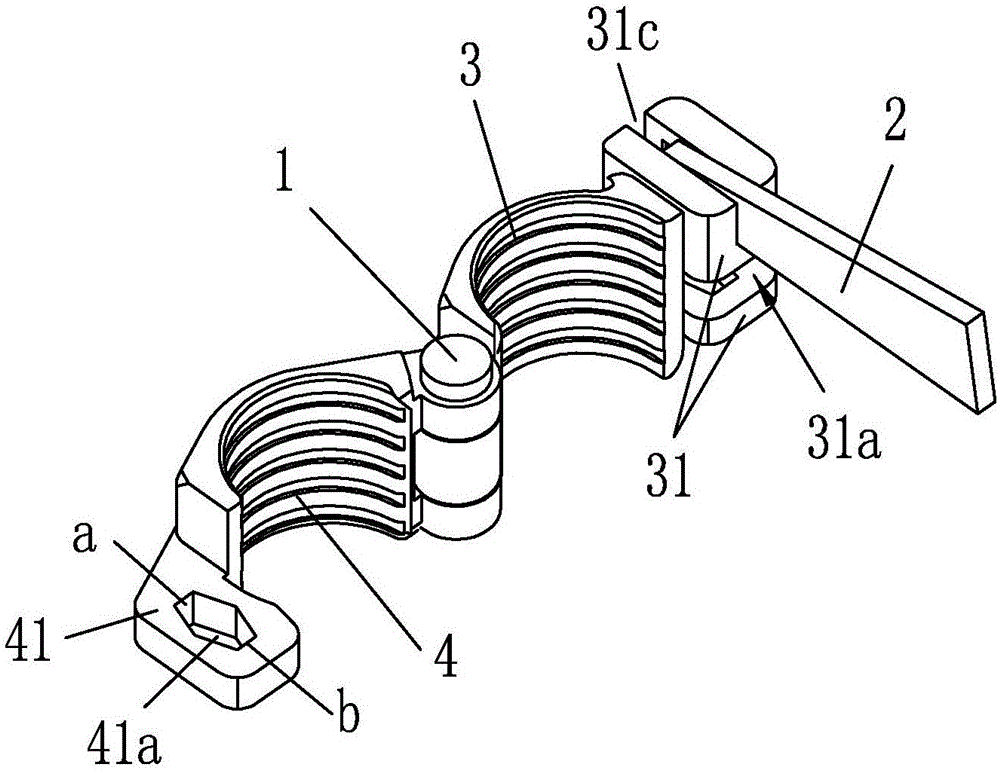

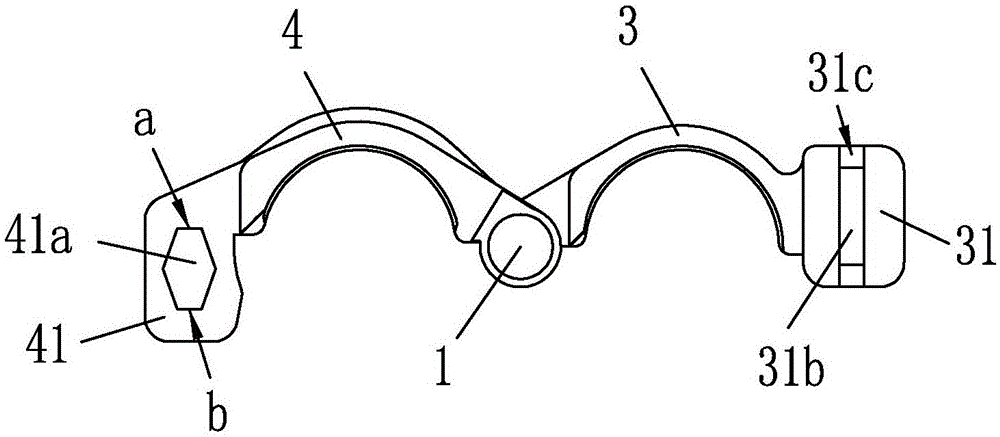

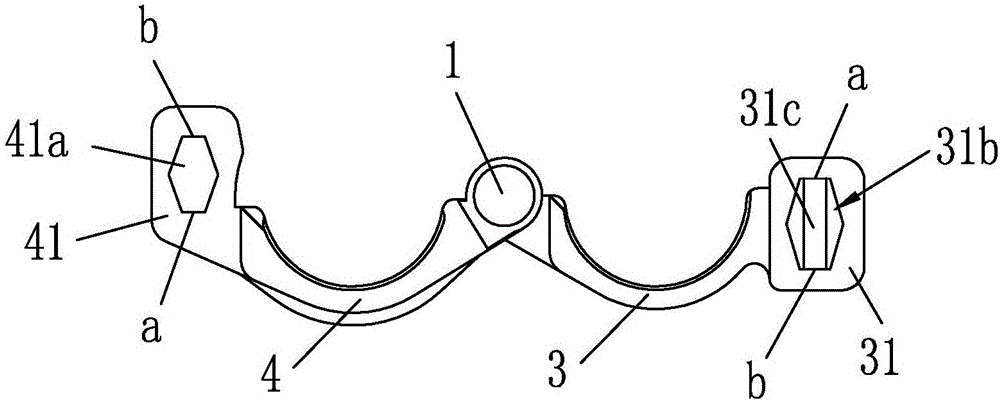

[0038] Example 1, see Figure 1~5 , a fast locking fastener unit, including a first semicircle clamp 3 and a second semicircle clamp 4 hinged by a pin 1 and locked by a wedge 2; the outer wall of the free end of the first semicircle clamp 3 There is a first connecting ear 31 extending in the radial direction, and a card groove 31a is formed in the middle of the thickness direction of the first connecting ear 31, and a first wedging hole 31b through the thickness is also formed on the first connecting ear 31; A second connecting ear 41 is formed on the outer wall of the free end of the hoop 4, and the second connecting ear 41 has a part that can extend into the slot 31a from one side of the first connecting ear 31. The second wedging hole 41a; after the wedge block 2 is wedged into the public space between the first wedging hole 31b and the second wedging hole 41a, the first semicircle clamp 3 and the second semicircle clamp 4 are locked , and when locking, the two locking wor...

Embodiment 2

[0040] Embodiment 2, a fast locking fastener unit, the distal end of the first connecting ear 31 is fixedly connected or integrally formed with a joint 5 having a cylindrical plug-in fitting section (not shown in the drawings).

[0041] The rest of the structure of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

Embodiment 3

[0042] Example 3, see Image 6 , 7 and combine Figure 1~5 , a fast locking fastener unit, the distal end of the first connecting ear 31 is fixedly connected or integrally formed with a joint 5 having a cylindrical plug-fitting section, and the first semicircular clamp 3 is provided with a third connecting ear 32; The second semicircle clamp 4 is provided with a fourth connecting ear 42, and the third connecting ear 32 and the fourth connecting ear 42 are all provided with a third locking hole locked by a wedge; the third locking hole on the third connecting ear 32 The tight hole and the first wedging hole 31b have a 90-degree phase difference; the third locking hole on the fourth connecting ear 42 has a 90-degree phase difference with the second wedging hole 41a; the first semicircular clamp 3 is also provided with The fifth connecting ear 33, the fifth connecting ear 33 is provided with a fourth locking hole 33a locked by a wedge, and the fourth locking hole 33a is corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com