Coating device and process for preparing filiform grain coating

A textured and silky technology, which is applied in the field of coating equipment for preparing silky textured coatings, can solve the problems that the weather resistance performance cannot reach the highest weather resistance quality, the size of the silk pattern cannot be adjusted at will, and the highest level of weather resistance cannot be met. Achieve overall stable color, simple structure and better effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

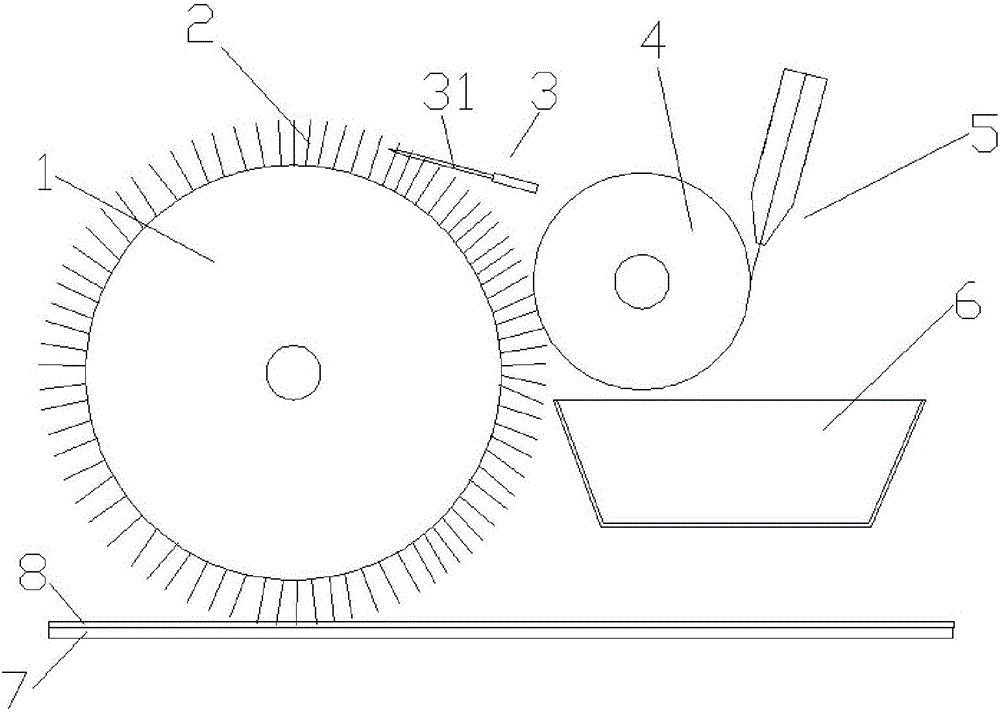

[0033] A coating device for preparing a filamentous textured coating, such as figure 1 As shown, it includes a substrate transmission mechanism, a bracket, a brush roller 1 arranged on the bracket, and a brush roller cleaning mechanism that cooperates with the brush roller 1. The surface of the brush roller 1 is provided with bristles 2, and the bristles 2 adopt nylon bristles, standing upright on the The surface of the brush roller 1 is arranged in a staggered manner, and the bristles 2 are in contact with the brush roller cleaning mechanism. The brush roller cleaning mechanism includes a bristle comb 3 and a liquid suction roller 4. The bristle comb 3 is provided with a plurality of comb needles 31 arranged side by side. Between, one end of the comb needle 31 is inserted between the bristles 2, and the other end is located outside the bristles 2, and the height of the end of the comb needle 31 inserted between the bristles 2 is higher than the height of the end outside the b...

Embodiment 2

[0037] This embodiment is basically the same as Embodiment 1, except that two brush rollers 1 are arranged in parallel in this embodiment, and each brush roller 1 is provided with a matching brush roller for cleaning. Mechanism, when using the device to paint the silky texture, the undried paint layer 8 is successively contacted with the bristles 2 of the two brush rollers 1, so that the pulled out silky texture is uniform and attractive.

Embodiment 3

[0039] A coating device for preparing a filamentary texture coating, comprising a bracket, a brush roller 1 arranged on the bracket and a brush roller cleaning mechanism matched with the brush roller 1, the surface of the brush roller 1 is provided with bristles 2, and the bristles 2 adopt Nylon bristles are arranged in a staggered manner, and the bristles 2 are in contact with the brush roller cleaning mechanism. The brush roller cleaning mechanism includes two bristle combs 3, each bristle comb 3 is provided with a plurality of comb needles 31 arranged side by side, the distance between the comb needles 31 is greater than the diameter of the bristles 2, and one end of the comb needles 31 is inserted between the bristles 2 , the other end is located outside the bristles 2, the height of the end where the comb needle 31 is inserted between the bristles 2 is higher than the height of the end outside the bristles 2, and a bristle comb is provided under each bristle comb 3 outside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com