A joint connection of recycled block concrete composite beam-column and its construction method

A technology of node connection and concrete beams, which is applied in the direction of architecture and building construction, can solve the problems of difficulty in placing large-scale waste concrete blocks in construction, and achieve the effects of reducing welding workload, high welding quality, and convenient placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

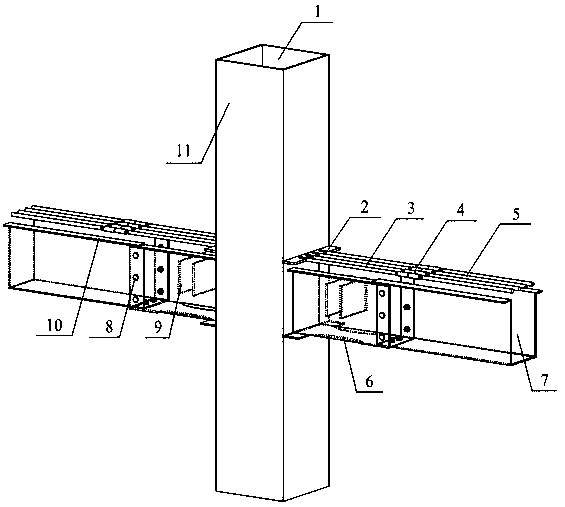

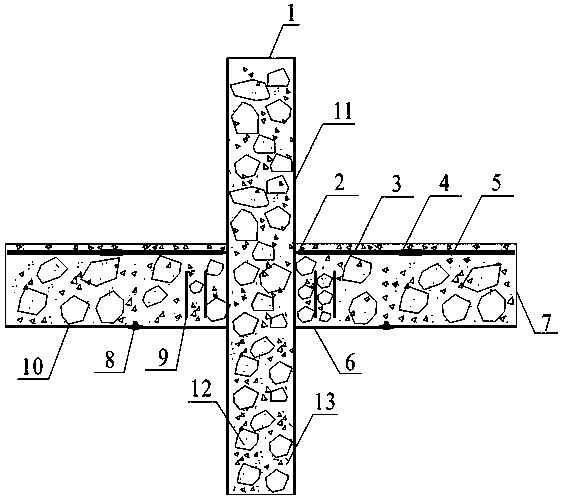

[0026] Such as figure 1 , 2 As shown, a recycled block concrete composite beam-column joint connection, including square steel pipe recycled block concrete column 1, U-shaped recycled block concrete beam 7 covered with steel, and U-shaped beam with partially weakened bottom plate and widened at one end Steel connecting piece 6, steel connecting plate 2 with grooves and short steel bar 3 with thread at one end; U-shaped steel connecting piece 6 with partially weakened bottom plate and widened at one end welded on the outer wall of square steel pipe 11 in the core area of the node and a grooved steel connecting plate 2; one end of a single-end threaded short steel bar 3 is welded in the groove of the grooved steel connecting plate 2, and the other end is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com