Self-flowing asphalt mixture mixer

A technology for asphalt mixture and mixing truck, which is applied in the directions of roads, road repair, roads, etc., can solve the problems of lack of production function and low efficiency, and achieve the effect of rapid temperature rise and increased heating area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

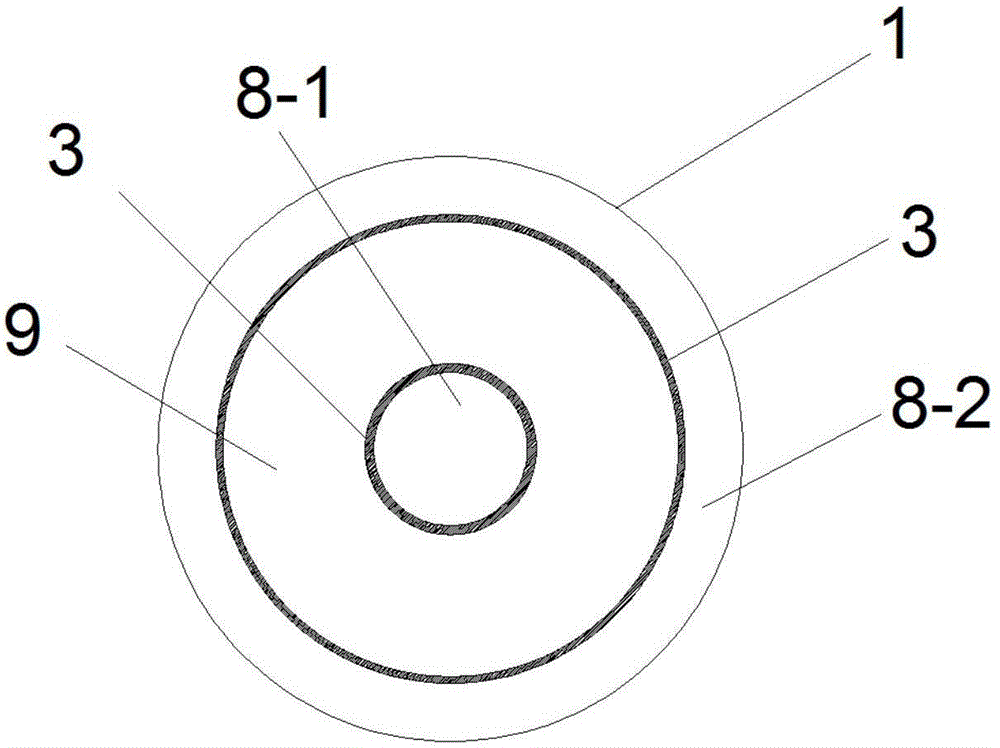

[0028] Such as figure 1 As shown in the self-flowing asphalt mixing truck, the bottom frame 14 is provided with a stirring pot 1, and the stirring pot 1 is provided with 3 coaxial circular drums. The tank 9 and the inner cylinder 8-1, the inner and outer walls of the middle cylinder stirring tank 9 are all provided with a cylinder wall protection layer 3, and the bottom of the outer cylinder 8-2 and the inner cylinder 8-1 are connected. The top of the stirring pot 1 is provided with a feeding port top cover 7, and the stirring shaft 2 extends into the stirring pot 1 from the feeding port top cover 7. A stirring impeller 5 is arranged on the stirring shaft 2, and is coaxial with the outer cylinder 8-2, the middle cylinder stirring tank 9 and the inner cylinder 8-1.

[0029] Wherein, three burners 6 are arranged on the bottom of the stirring pot 1, and the diesel tank 10 arranged on the bottom frame 14 provides fuel for the burners 6; wherein, one burner 6 is positioned at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com