A kind of heat-conducting anisotropic SIC composite ceramic bulk material and its preparation method

A technology of composite ceramics and bulk materials is applied in the field of inorganic non-metallic materials to achieve the effects of low cost, broad application prospects and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

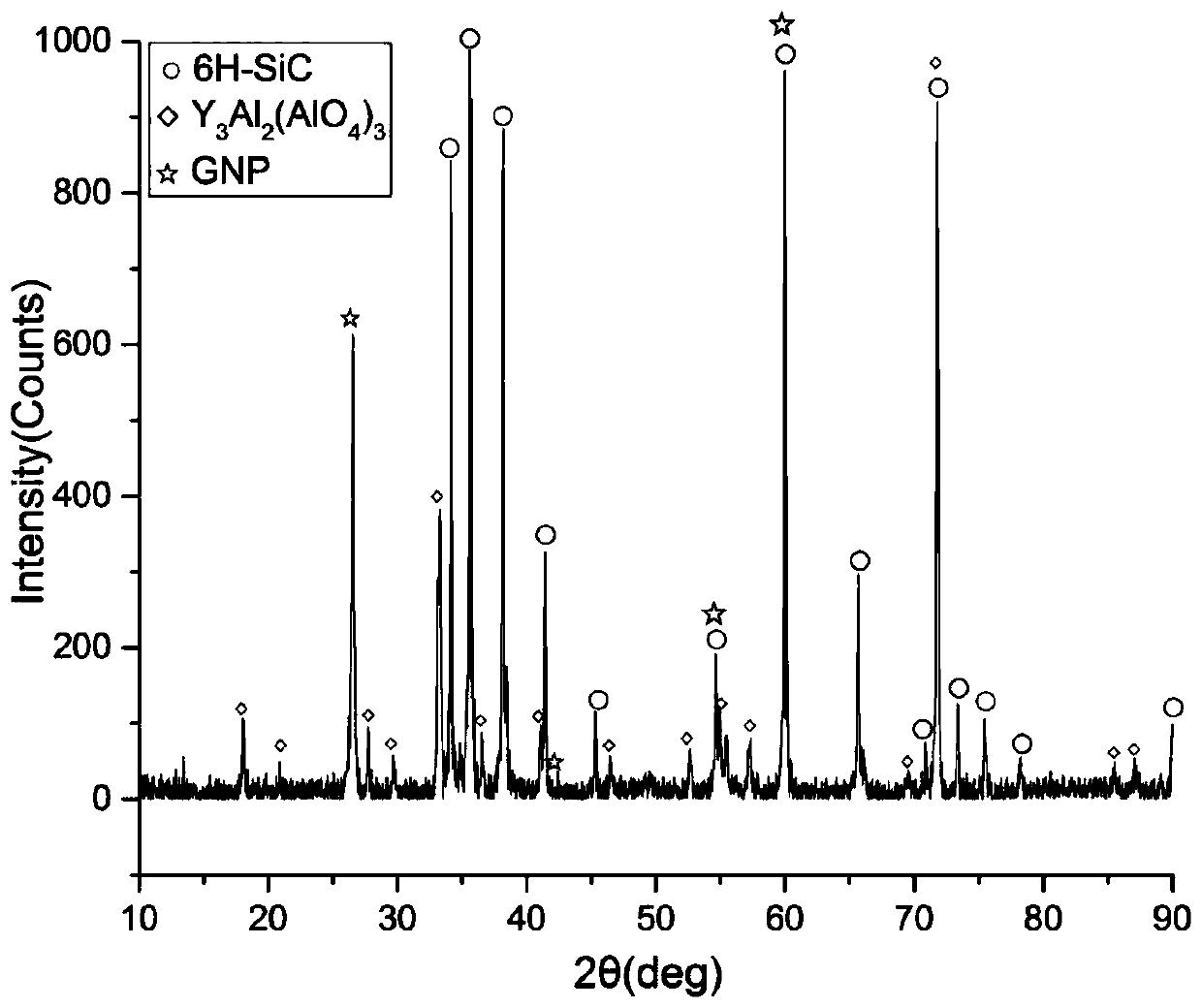

Embodiment 1

[0033] Preparation of thermally conductive anisotropic SiC composite ceramic bulk material containing 5wt% graphene:

[0034] Step 1. 85.5g of silicon carbide with an average particle size of 0.5 μm, 5 g of graphene with a diameter of 5 μm to 10 μm, 5.42 g of yttrium oxide with an average particle size of 0.3 μm, 4.08 g of aluminum oxide with an average particle size of 0.5 μm, and Put zirconia balls with different particle sizes into the ball milling jar, then add absolute ethanol to 2 / 3 of the volume of the ball milling jar, then place the ball milling jar in an ultrasonic instrument for 30 minutes, and then put it into a planetary ball mill at 400r / Ball mill for 6 hours at a rotating speed of 1 min to obtain a uniformly mixed slurry; put the uniformly mixed slurry into a rotary evaporator heated by a water bath, and then remove anhydrous ethanol, and then place the rotary-evaporated solid in a constant temperature drying oven at 80°C for 24 hours to obtain a dry powder;

...

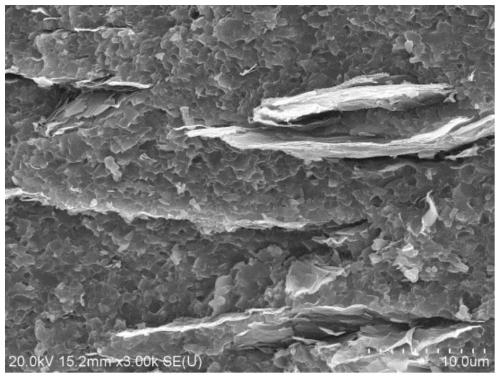

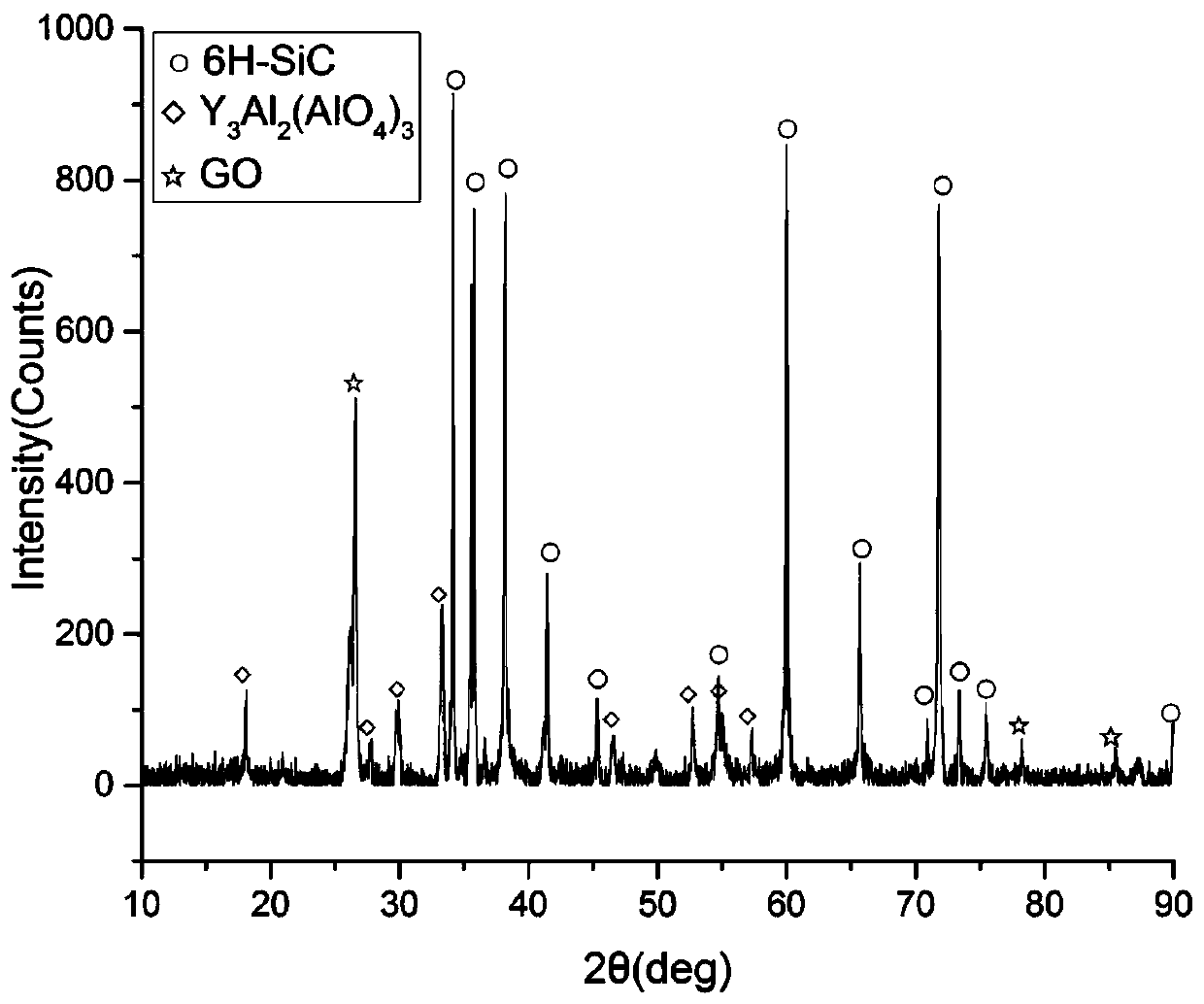

Embodiment 2

[0040] Preparation of thermally conductive anisotropic SiC composite ceramic bulk material containing 5wt% graphene oxide:

[0041] Step 1. 85.5g of silicon carbide with an average particle size of 0.5μm, 5g of graphene oxide with a diameter of 1μm to 5μm, 5.42g of yttrium oxide with an average particle size of 0.3μm, and 4.08g of alumina with an average particle size of 0.5μm And zirconia balls with different particle sizes are added to the ball milling tank, then add absolute ethanol to 2 / 3 of the volume of the ball milling tank, and then put the ball milling tank in an ultrasonic instrument for 30 minutes, and then put it into a planetary ball mill at 400r Ball milling at a rotating speed of 30r / min for 6 hours to obtain a uniformly mixed slurry; put the uniformly mixed slurry into a rotary evaporator heated by a water bath, and then remove impurities at a rotating speed of 30r / min and a heating temperature of a water bath of 70°C. water and ethanol, and then place the rota...

Embodiment 3

[0047] Preparation of thermally conductive anisotropic SiC composite ceramic bulk material containing 3wt% graphene:

[0048] Step 1. 87.3g of silicon carbide with an average particle size of 0.5 μm, 3 g of graphene with a diameter of 5 μm to 10 μm, 5.53 g of yttrium oxide with an average particle size of 0.3 μm, 4.17 g of aluminum oxide with an average particle size of 0.5 μm, and Put zirconia balls with different particle sizes into the ball milling jar, then add absolute ethanol to 2 / 3 of the volume of the ball milling jar, then place the ball milling jar in an ultrasonic instrument for 30 minutes, and then put it into a planetary ball mill at 300r / Ball mill for 8 hours at a rotating speed of min to obtain a uniformly mixed slurry; put the uniformly mixed slurry into a rotary evaporator heated by a water bath, and then remove anhydrous ethanol, and then place the rotary-evaporated solid in a constant temperature drying oven at 100°C for 20 hours to obtain a dry powder;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com