High-pressure gas-liquid separation control device and control method thereof

A control device and liquid separation technology, applied in electrical program control, program control in sequence/logic controllers, measurement devices, etc., can solve problems such as insufficient separation capacity of low-pressure separators, and achieve easy maintenance and replacement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

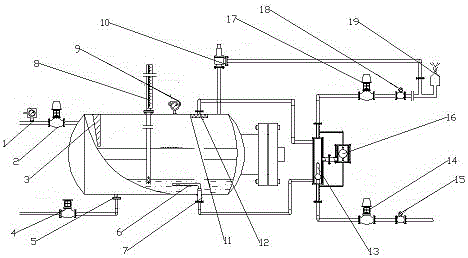

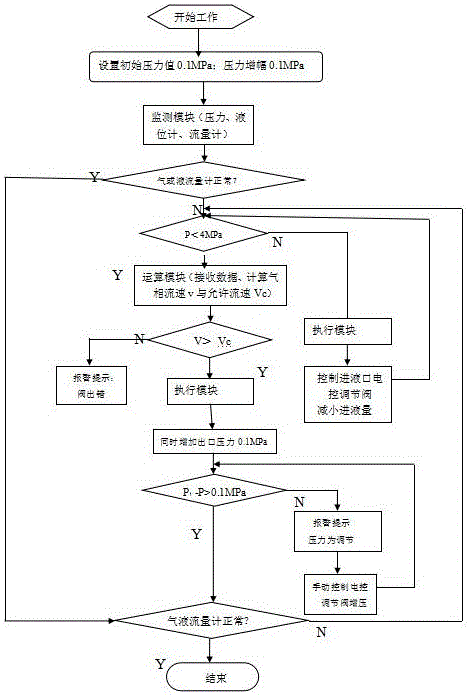

[0048] This embodiment provides a high-pressure gas-liquid separation control device, such as figure 1 As shown, it includes a separation tank, the separation tank is connected with a liquid inlet line, and the separation tank is provided with a liquid outlet 7, an air outlet 12 and a sewage outlet 5. The separation tank can be a horizontal or vertical separation tank. In this embodiment, A horizontal separation tank is used, and its gas phase processing capacity is 3 to 5 times that of a vertical separator. The separation tank is also equipped with a magnetic flap level gauge 8 and a temperature and pressure transmitter 9 for real-time detection and separation. device working condition.

[0049] A pressure transmitter 1 and a liquid inlet electric control valve 2 are provided on the liquid inlet line, and a rectifying plate 3 is provided at the liquid inlet of the separation tank connected to the liquid inlet line. The sewage outlet 5 is connected to the sewage pipeline, and...

Embodiment 2

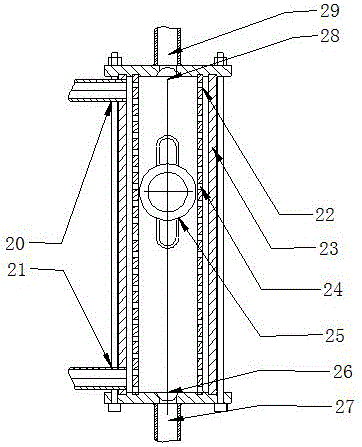

[0064] In order to realize that when the gas-liquid ratio changes greatly, the liquid outlet can only output liquid, and the gas outlet can only output gas. In this embodiment, the coaxial float valve 13 and the balance valve 16 are installed outside the separation tank, which is convenient for replacement and maintenance. The air inlet of the coaxial float valve 13 is level with the highest liquid level inside the separator, and the liquid inlet of the coaxial float valve 13 is lower than the lowest liquid level inside the separator by a float height.

[0065] Such as image 3 As shown, in this embodiment, the coaxial float valve 13 adopts an interlocking float, and the coaxial float valve 13 includes a coaxial float valve shell 23 and a coaxial float valve inner shell 22 coaxially set, and the upper part of the coaxial float valve shell 23 The coaxial float valve inlet 20 and the coaxial float valve liquid inlet 21 are respectively arranged on the bottom and the coaxial flo...

Embodiment 3

[0086] Based on the structures in the above two embodiments, in the present embodiment, the liquid outlet 7 at the bottom of the separation tank is provided with a liquid level stabilizer 6, such as Figure 5 As shown, the liquid level stabilizer 6 is a column structure with one end closed horizontally, the bottom side of the column is evenly distributed with liquid inlet holes, and the outlet at the end of the column communicates with the liquid outlet 7 . The gas outlet 12 on the top of the separation tank is provided with a mist catcher 11 . The separator is also connected to a safety valve 10 through a pipeline, and the exhaust pipe connected to the coaxial float valve 13 is communicated with the safety valve 10 through a branch line.

[0087] The liquid outlet 7 of the separation tank can form a concave vortex when discharging liquid, and suck the air flow. The larger the concave vortex, the stronger the gas phase suction volume, and the more serious the gas cone phenome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com