Male mold of blade mold and its modification method, adjustment method of blade pre-bending

A technology of male molds and blades, which is applied to household appliances, other household appliances, household components, etc., can solve problems such as insufficient headroom, and achieve the effects of reducing losses, realizing steps, and ensuring connection reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

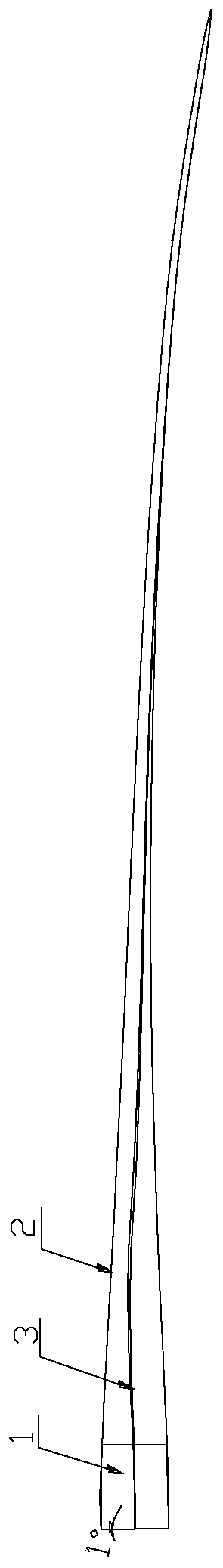

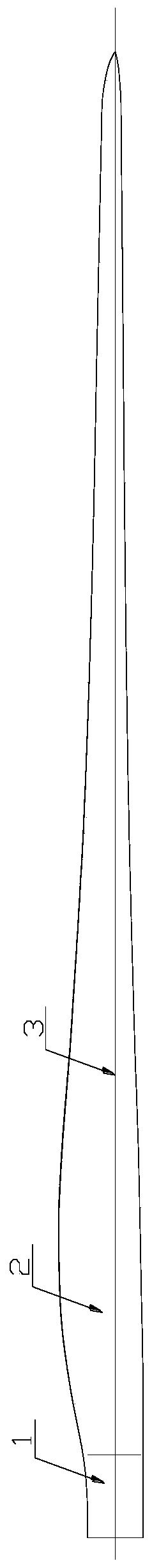

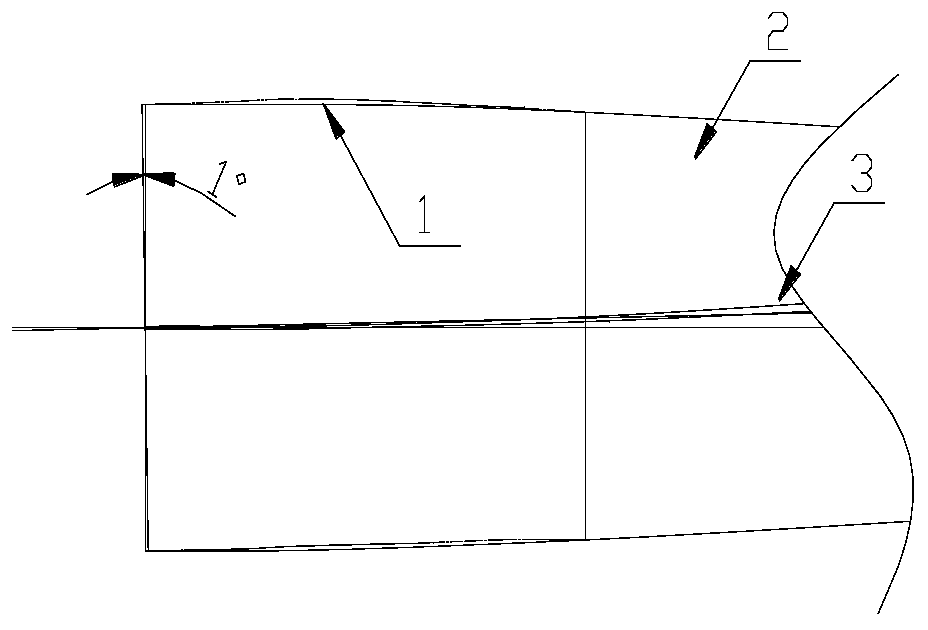

[0033] The purpose of the present invention is to provide a male mold of the blade mold and its modification method, and a method of adjusting blade pre-bending. Before developing the female mold, the blade root part of the male mold is modified to change the pre-bending amount of the blade, thereby solving the lack of headroom The problem can greatly reduce the loss caused by the development of the blade mold in the early stage, and at the same time save the increased cost of the re-production of the blade die.

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can accurately understand the technical solution of the present invention.

[0035] The orientation in this article is based on the wind turbine unit, and the extension direction of the tower tube of the wind turbine unit is vertical. In the vertical direction, the direction pointing to the ground or sea level is down, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com