Working table for FDM printing equipment

A technology of printing equipment and workbench, applied in the direction of additive processing, coating devices, processing heating elements, etc., can solve the problem of inconvenient disassembly of the mold, difficult to control mold wrinkling, and difficult to control the deformation and wrinkling around the mold. and other problems, to achieve the effect of improving the shape accuracy and reducing the casting cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

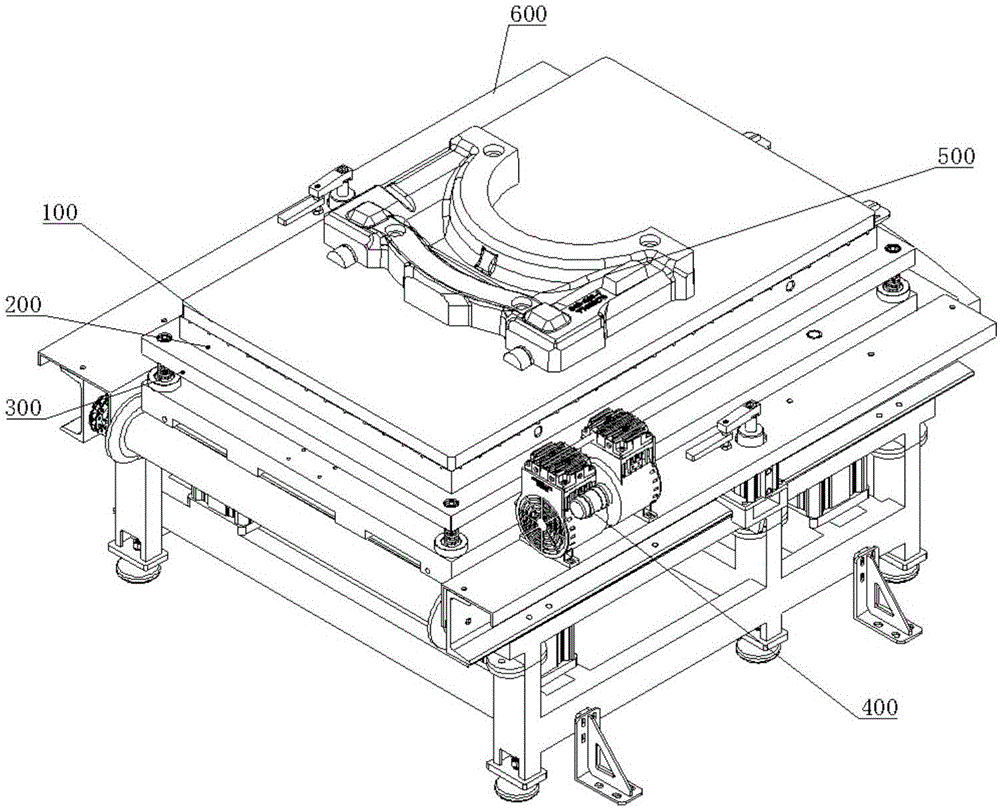

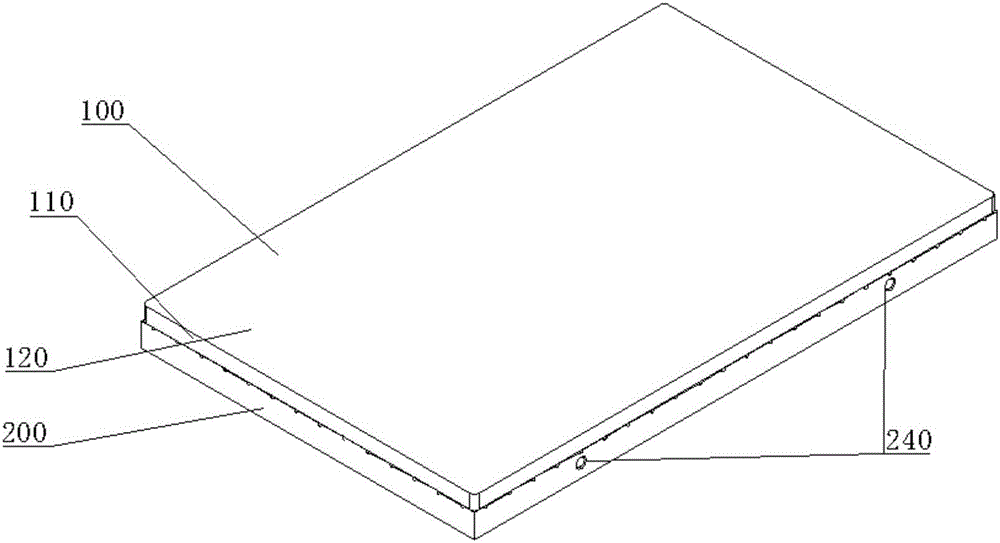

[0021] Such as Figure 1 to Figure 3 As shown, an embodiment of the present invention provides a workbench for FDM printing equipment, including an adsorption platform 100, the first surface of the adsorption platform 100 is coated with a coating 120 of a first material, and the opposite side of the first surface The second surface is thermally coupled with the heating plate 300, wherein the coating layer 120 is non-sticky at normal temperature, and is bonded to the printing mold under heating.

[0022] It should be understood that the above-mentioned coating layer 120 may be a thermoplastic resin material, such as polyamide, polyoxymethylene, polycarbonate and the like. In addition, some hot-melt adhesives that can realize the above functions can also be used as coatings, which can be determined according to specific usage conditions, and the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com