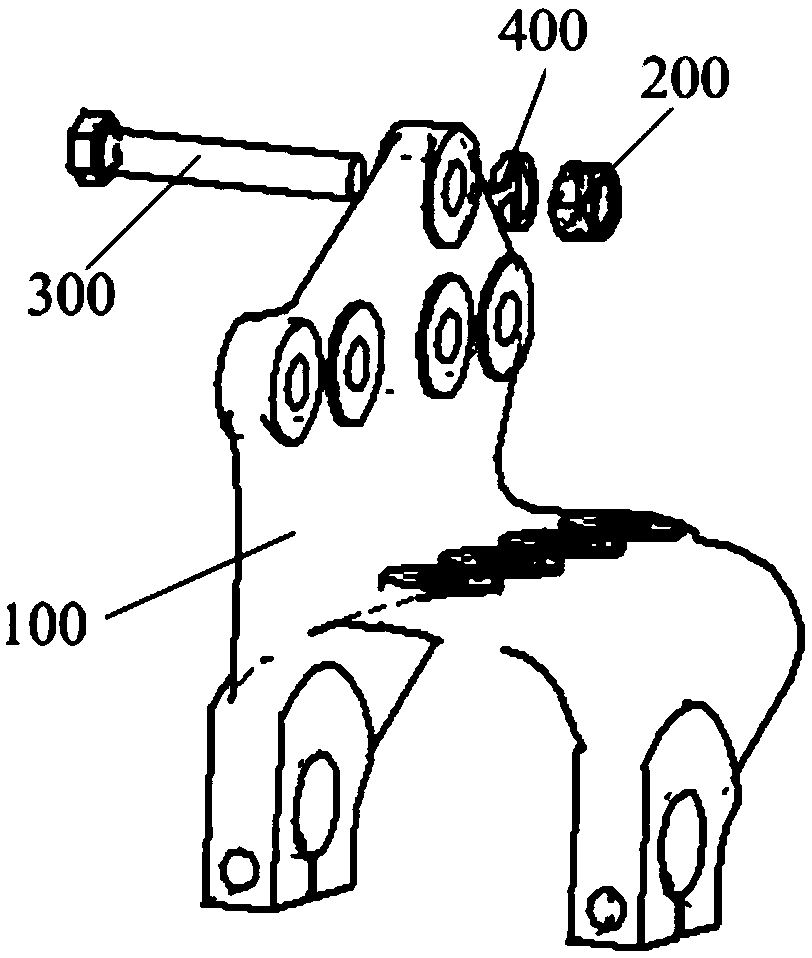

Nut positioning and anti-loosening device

A nut positioning and anti-loosening technology, applied in the direction of manufacturing tools, hand-held tools, etc., can solve the problems of difficulty in fixing nut 200, single structure, general effect, etc., to improve assembly, save human resources, and improve installation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

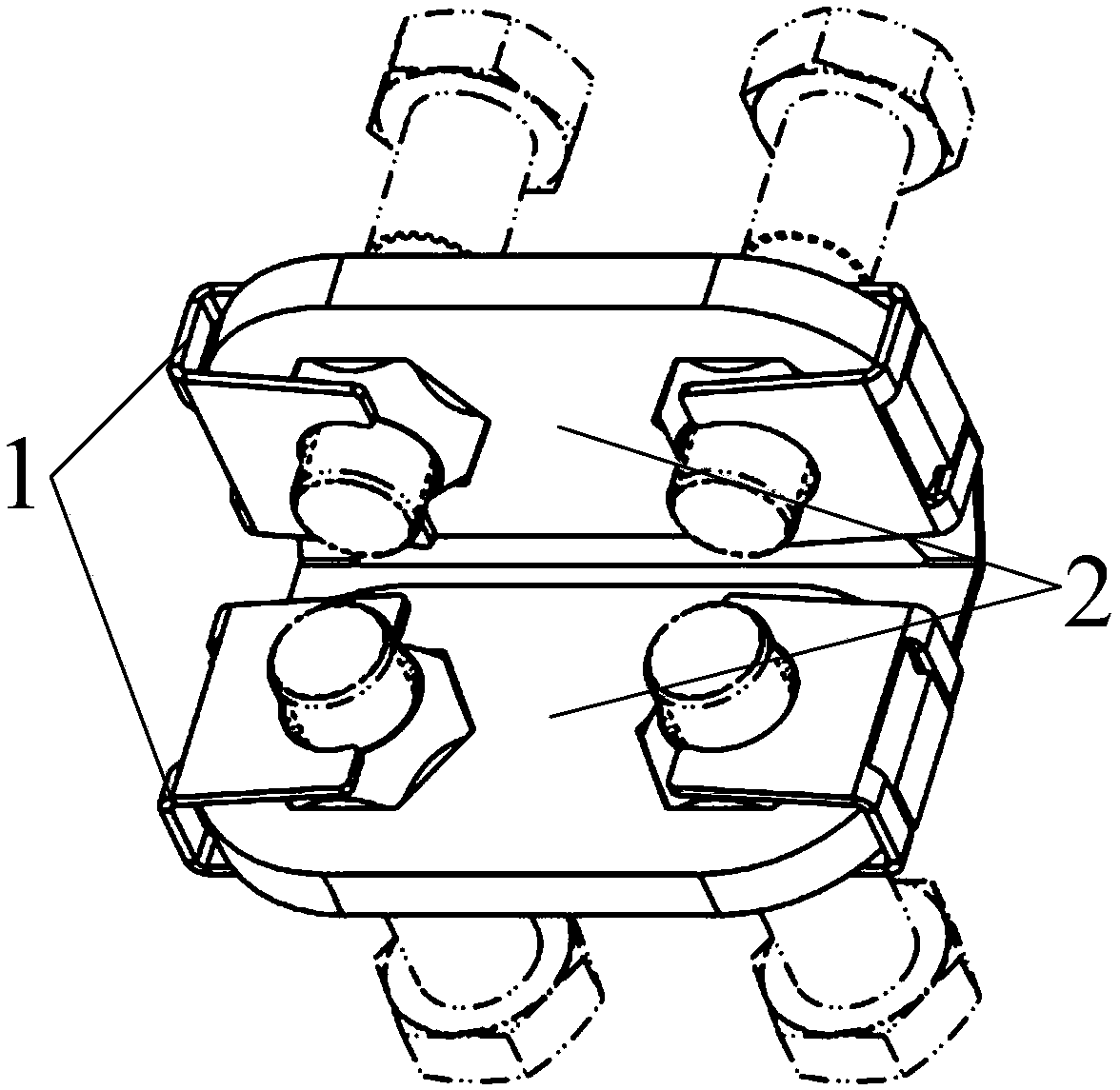

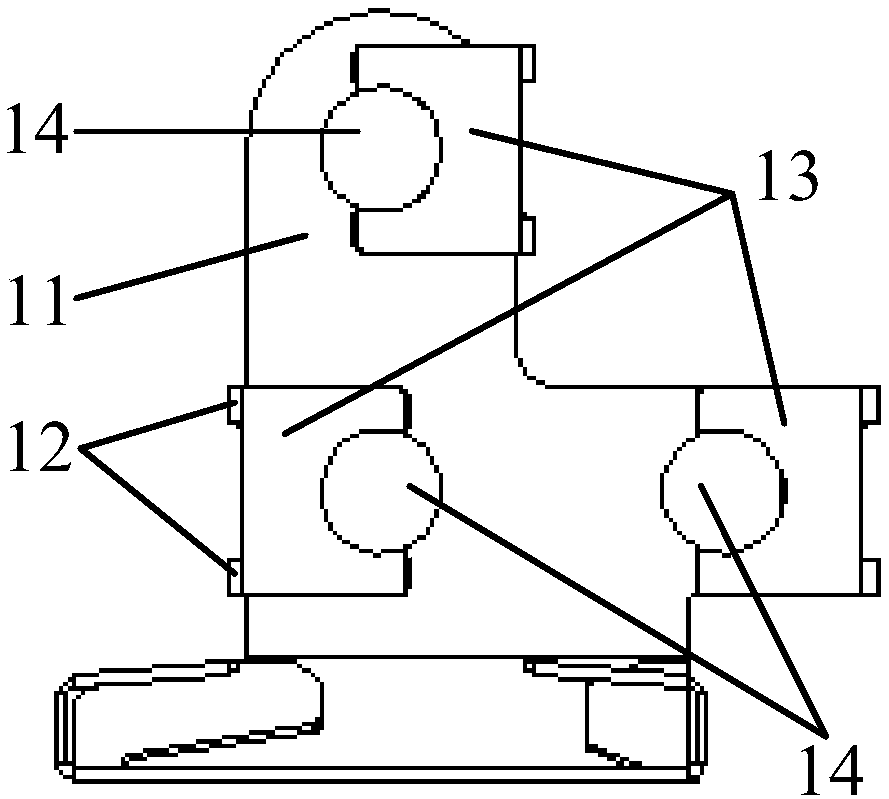

[0021] Embodiments of the present invention: as figure 2 , image 3 with Figure 4 As shown, a nut positioning and anti-loosening device includes a frame 1 and a liner 2, the frame 1 and the liner 2 are made of Q235 steel, the frame 1 includes a frame body 11, a connecting plate 12 and Limiting plate 13, the frame body 11 is provided with several screw mounting holes 14, the limiting plate 13 is connected with the frame body 11 through the connecting plate 12, and the limiting plate 13 can be connected along the connecting plate 12. The plate 12 is folded at any angle, each of the limiting plates 13 has a screw mounting hole 14 to cooperate with it, and the end of each of the limiting plates 13 is provided with a semicircular groove 15, so The semicircular groove 15 is used for the inevit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com