Connecting rod drive type clamp

A connecting rod drive and fixture technology, applied in the mechanical field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

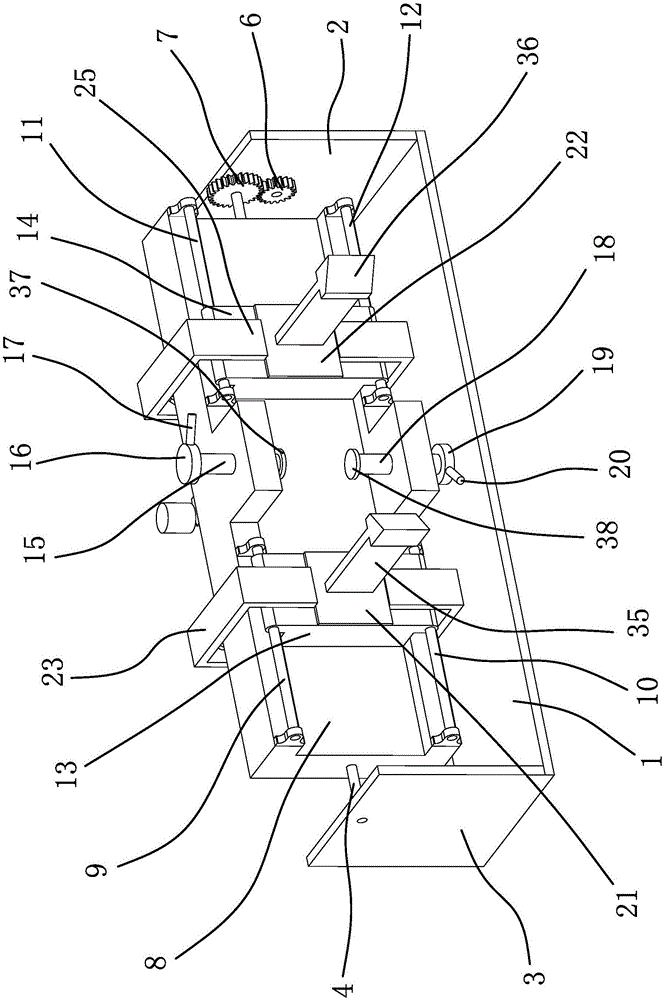

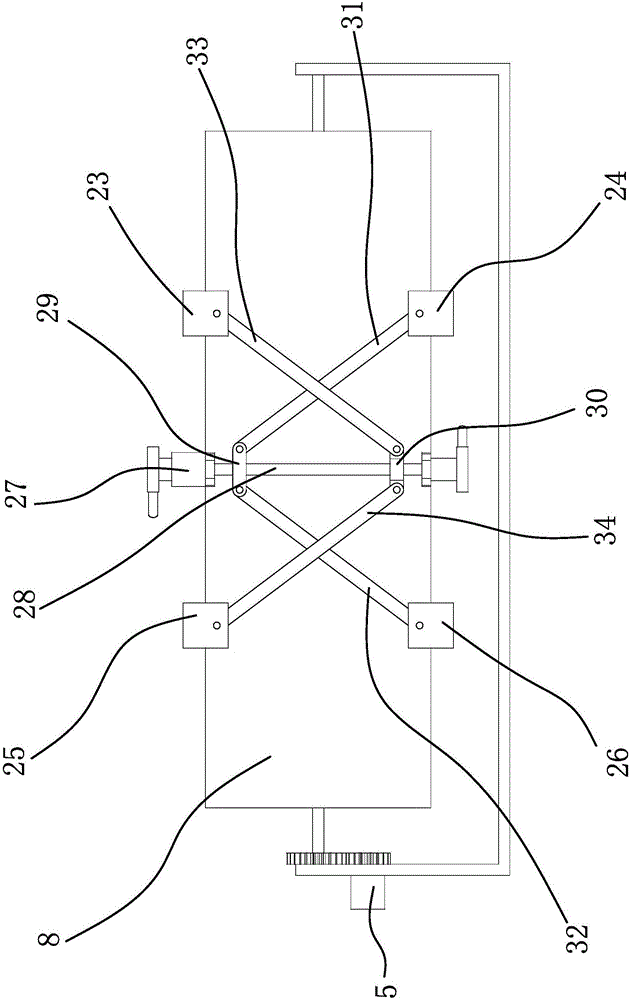

[0028] like figure 1 As shown, a link-driven clamp includes an outer frame, a clamping block one 35 , a clamping block two 36 , a clamping block three 37 and a clamping block four 38 . The outer frame comprises a base plate 1 and a vertical plate 1 and a vertical plate 2 3 fixed on the base plate 1. A rotating shaft 4 is horizontally arranged between the vertical plate 1 2 and the vertical plate 2 3. The vertical plate 1 2 is provided with a shaft that can drive the shaft 4. The rotating mechanism that rotates, the rotating mechanism includes a rotating motor 5, and the rotating motor 5 is fixed on the riser-2, and an end of the output shaft of the rotating motor 5 passing through the riser-2 is fixed with a driving gear 6, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com