Device for welding pothook

A hanging ring and hinged technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment and other directions, can solve the problems of affecting the welding quality of products, not being able to be fixed well, and low welding assembly efficiency, so as to improve welding assembly efficiency, Convenient operation and the effect of improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

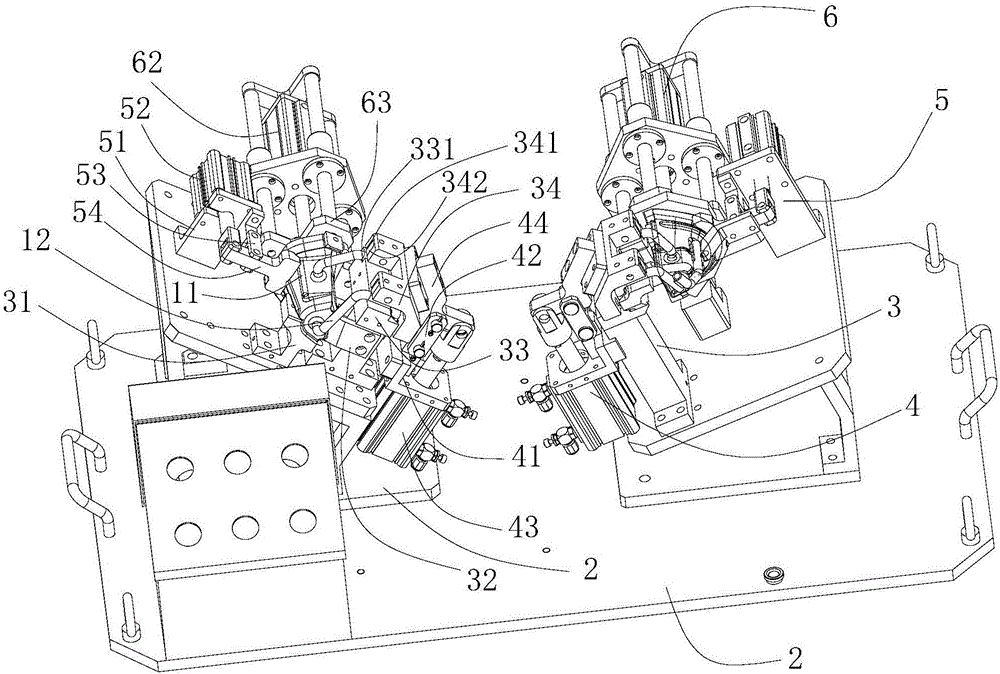

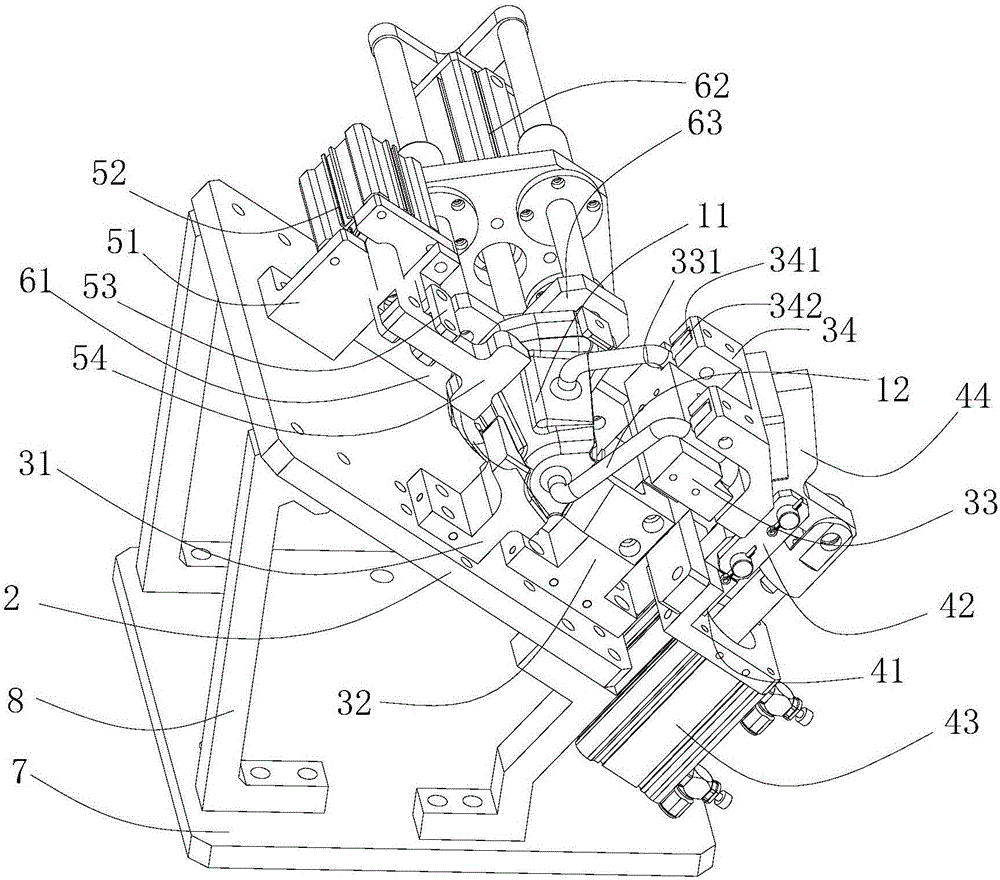

[0018] refer to Figure 1 to Figure 2 , is a device for hook welding, the hook includes a hook cover 11 and a hanging ring 12 arranged on the hook cover 11, the device for hook welding includes a fixing plate 2, and the hook cover 11 is placed sideways from the top to the bottom surface The central axis of the direction is parallel to the fixed plate 2, and the fixed plate 2 is provided with a first supporting mechanism 3 for supporting the hook, a first clamping mechanism 4 for clamping the hanging ring 12, and a clamping mechanism 4 for clamping the side of the hook cover 11. The second clamping mechanism 5 and the second supporting mechanism 6 for supporting the bottom surface of the hook cover 11 .

[0019] The first supporting mechanism 3 , the first clamping mechanism 4 , the second clamping mechanism 5 , and the second supporting mechanism 6 form an enveloping clamping on the hook from all directions, so that it is firmly fixed and the welding process is performed.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com