Preparation and application of palladium-ruthenium bimetallic nanocatalysts in hydrogenation

A bimetallic nano-catalyst technology, applied in the field of catalysts containing palladium and ruthenium, can solve the problems of complex raw materials and achieve the effects of uniform particle distribution, cost reduction, and efficient hydrogenation of NBR

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1) The salt of palladium and ruthenium is mixed, dissolved in water, the ratio of two kinds of soluble salt total moles to water volume is 0.02mol / L, the salt K of described palladium 2 PdCl 4 , the salt of ruthenium is RuCl 3 ; The mol ratio that the salt of palladium and ruthenium mixes is 1:1;

[0040] 2) Add the mixed metal salt solution into a 0.2 mol / L aqueous solution of polyvinylpyrrolidone (PVP), and stir for 3 hours at room temperature, wherein the ratio of the moles of PVP to the sum of the moles of the two metal salts is 30;

[0041]3) Put the mixed solution of the obtained metal salt and PVP into a microwave reactor, the microwave power is 800W, react at 150°C for 2h, wash the obtained black solution with acetone, and the centrifugal speed is 10000rpm, and the black precipitate obtained by separation is The product, PdRu BMNPs, was dissolved in ethanol or dried in vacuum for use.

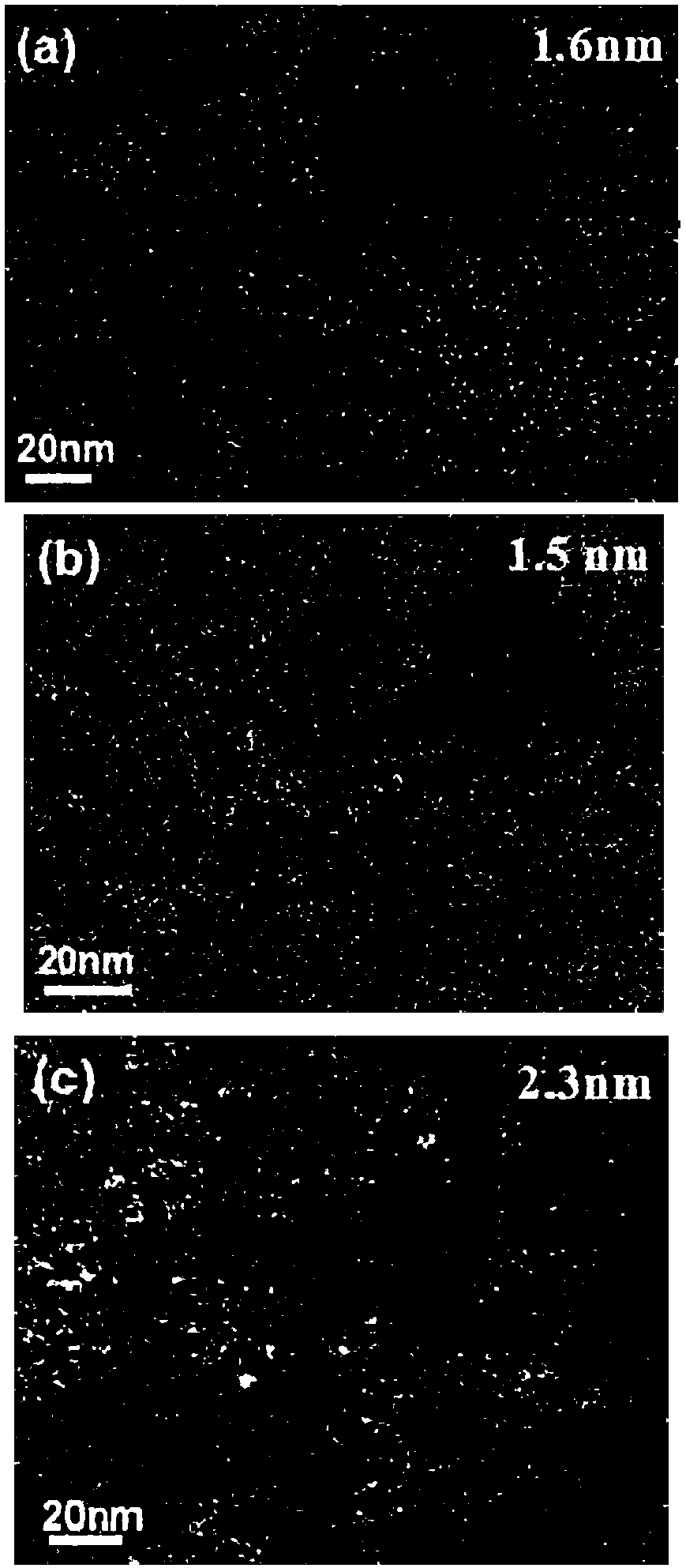

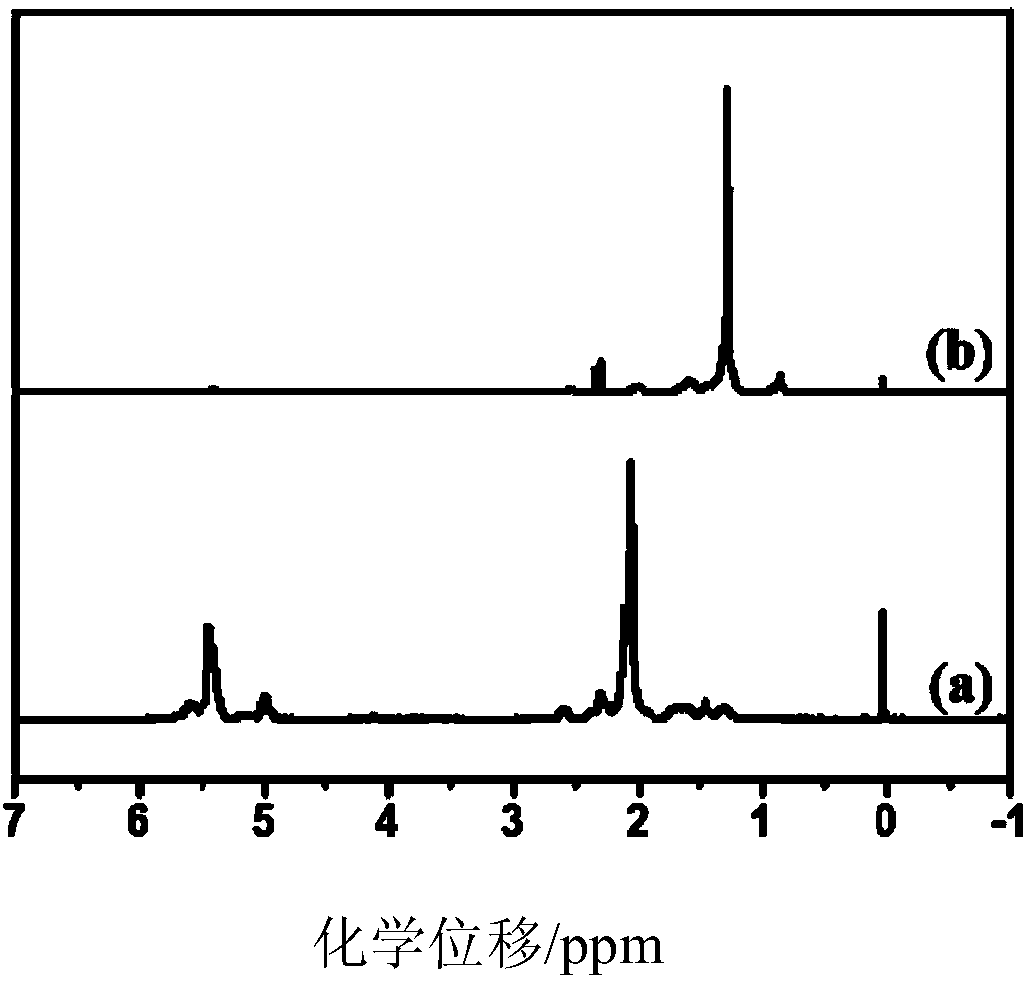

[0042] After the prepared PdRu BMNPs are dissolved in ethanol, the nanopa...

Embodiment 2

[0044] Prepare PdRu BMNPs catalyst according to embodiment 1 method, wherein K 2 PdCl 4 with RuCl 3 The mol ratio is set to 5:5, and in step 2), the ratio of the sum of the moles of PVP and the two metal salts is 20.

[0045] Produced Pd 5 Ru 5 BMNPs.

Embodiment 3

[0056] According to the steps of preparing PdRu BMNPs catalysts in Example 2, the microwave reaction temperature was set to 100°C, 120°C, and 180°C respectively, and PdRu BMNPs were prepared at different microwave reduction temperatures, which were respectively denoted as PdRu-100, PdRu-120, and PdRu -180, the nanoparticles prepared under the microwave reaction temperature of 150° C. in Example 2 are designated as PdRu-150.

[0057] The hydrogenation conditions are the same as in Test Example 1, and the hydrogenation results are shown in Table 2.

[0058] Table 2 Effect of different microwave reduction temperatures on Pd 5 Ru 5 Effect of Catalytic Hydrogenation of NBR

[0059]

[0060]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap