A needle clamp kit

The technology of a needle head and a jig is applied in the field of clamping devices, which can solve the problems of scrapping, unable to insert the needle, and increase the offset, and achieve the effects of convenient use, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

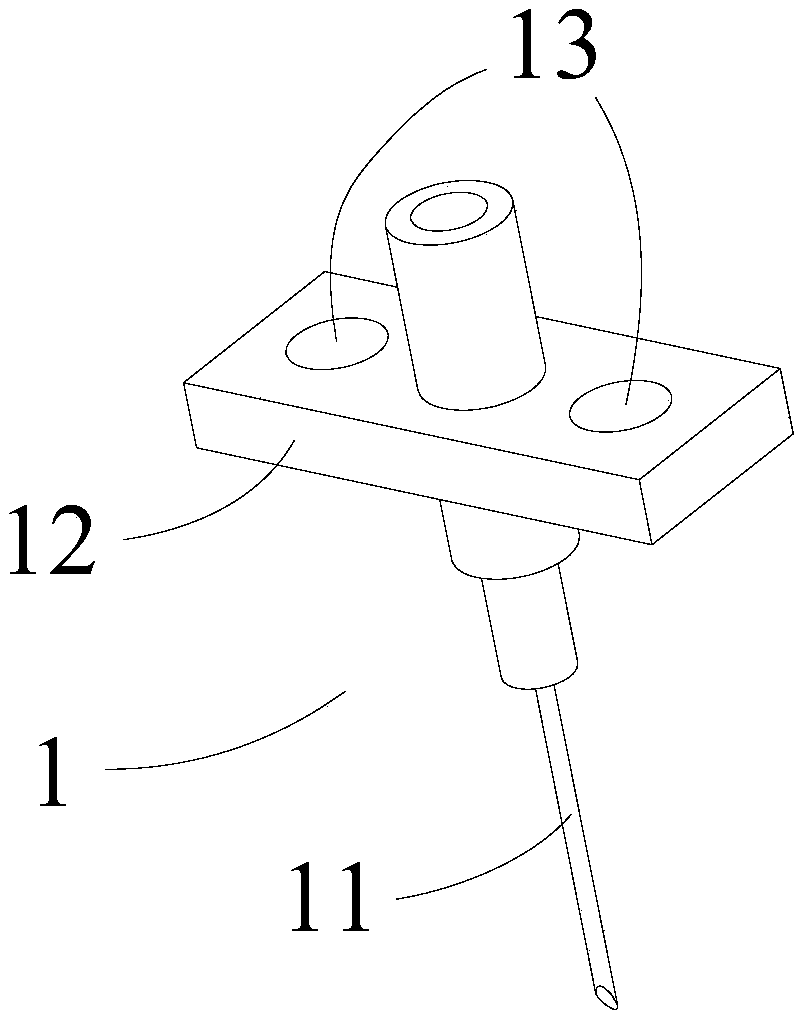

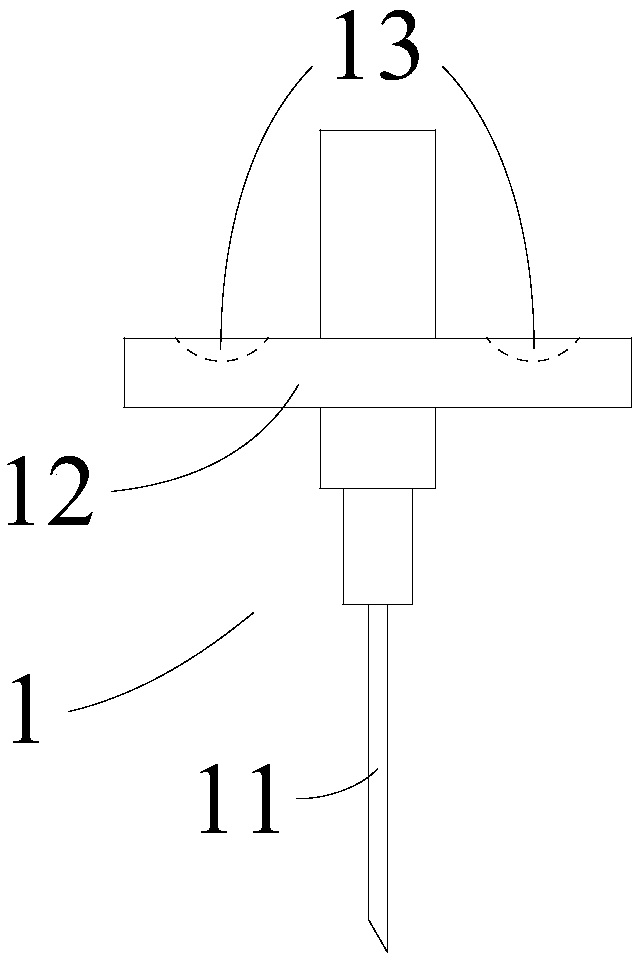

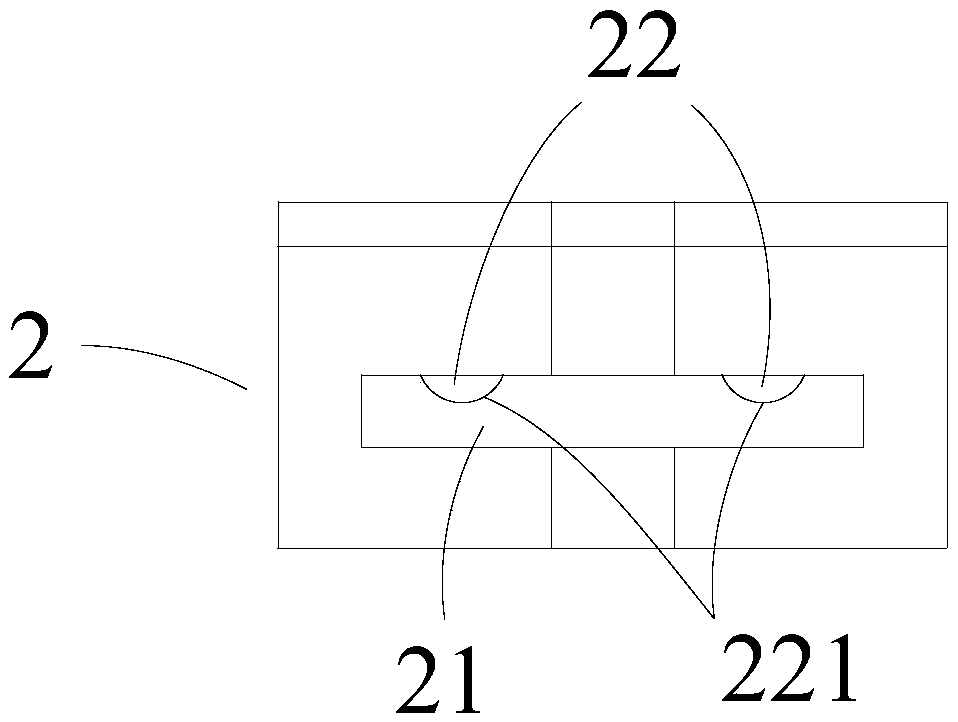

[0034] like Figure 1-5 As shown in the present invention, a needle 11 fixture set includes a clamping plate 1 and a clamping head 2 .

[0035] like figure 1 and 2 As shown, the clamping plate 1 includes a positioning piece 12 connected to the needle head 11, and the positioning piece 12 is provided with two spherical grooves 13, such as image 3 and 4 As shown, the chuck 2 includes a box body 23, and the box body 23 is provided with a locking groove 21 and at least one elastic lock head 22, and all the elastic lock heads 22 are arranged in the box body 23, each Each of the elastic lock heads 22 includes a spherical end 221, and the spherical end 221 can freely expand and contract in the engaging groove 21, and the engaging groove 21 is adapted to the positioning piece 12, and each of the spherical surfaces The end portion 221 is adapted to the spherical groove 13 .

[0036] Wherein, the needle head 11 and the positioning piece 12 are integrally formed to form the clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com