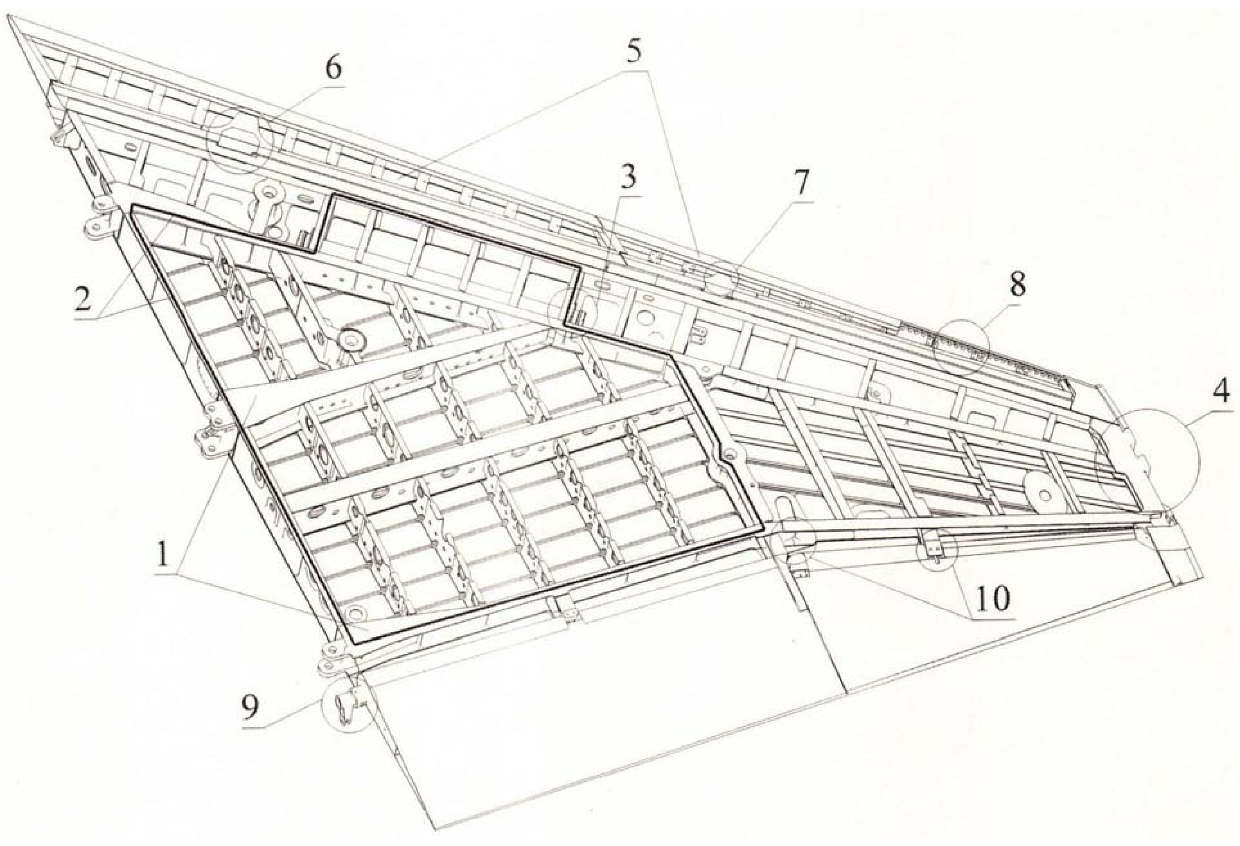

light fighter wing

A technology for fighter jets and wings, applied in the direction of wings, fuselage, aircraft parts, etc., to achieve the effect of meeting the strength, meeting the use and maintenance requirements, and simple installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

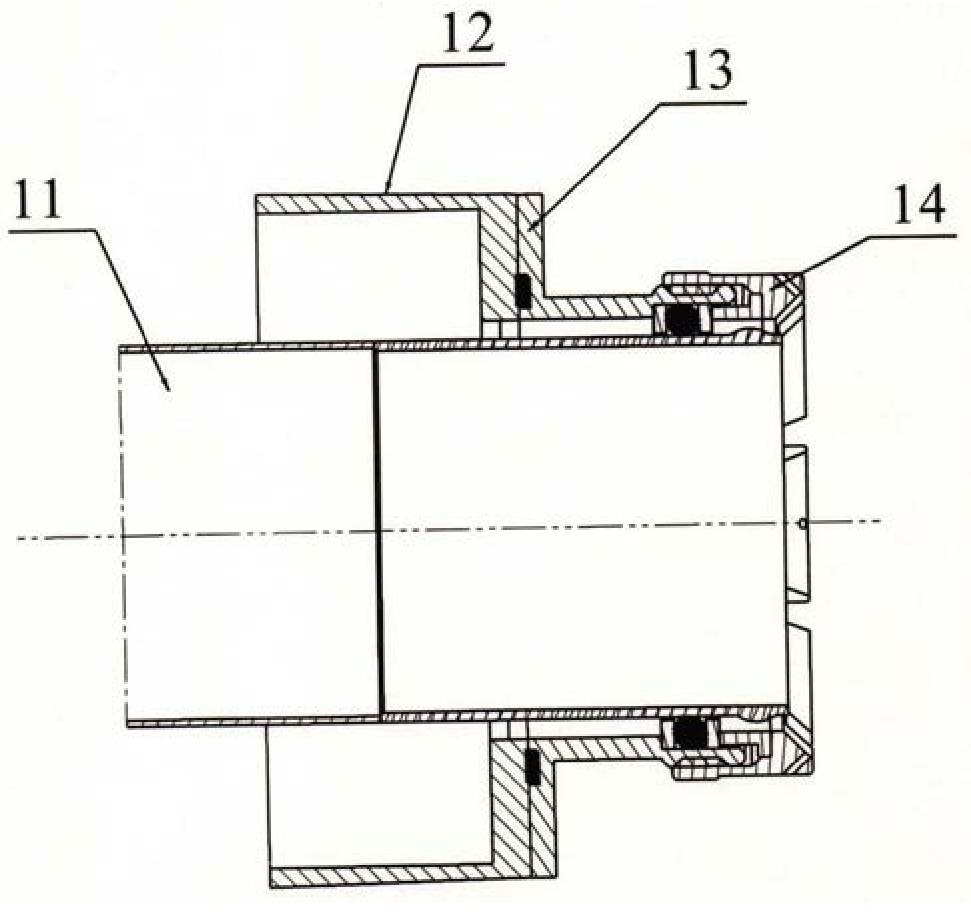

[0024] The swivel bearing material of the front skirt is made of stainless steel. Since the main girder and the rear girder are soaked in fuel oil, the main bearing girder 1 can

[0028] Fig. 3 has described the wing hanging wingtip projectile structure 4 shown in Fig. 1. Wingtip projectile structure design, in domestic light fighter design

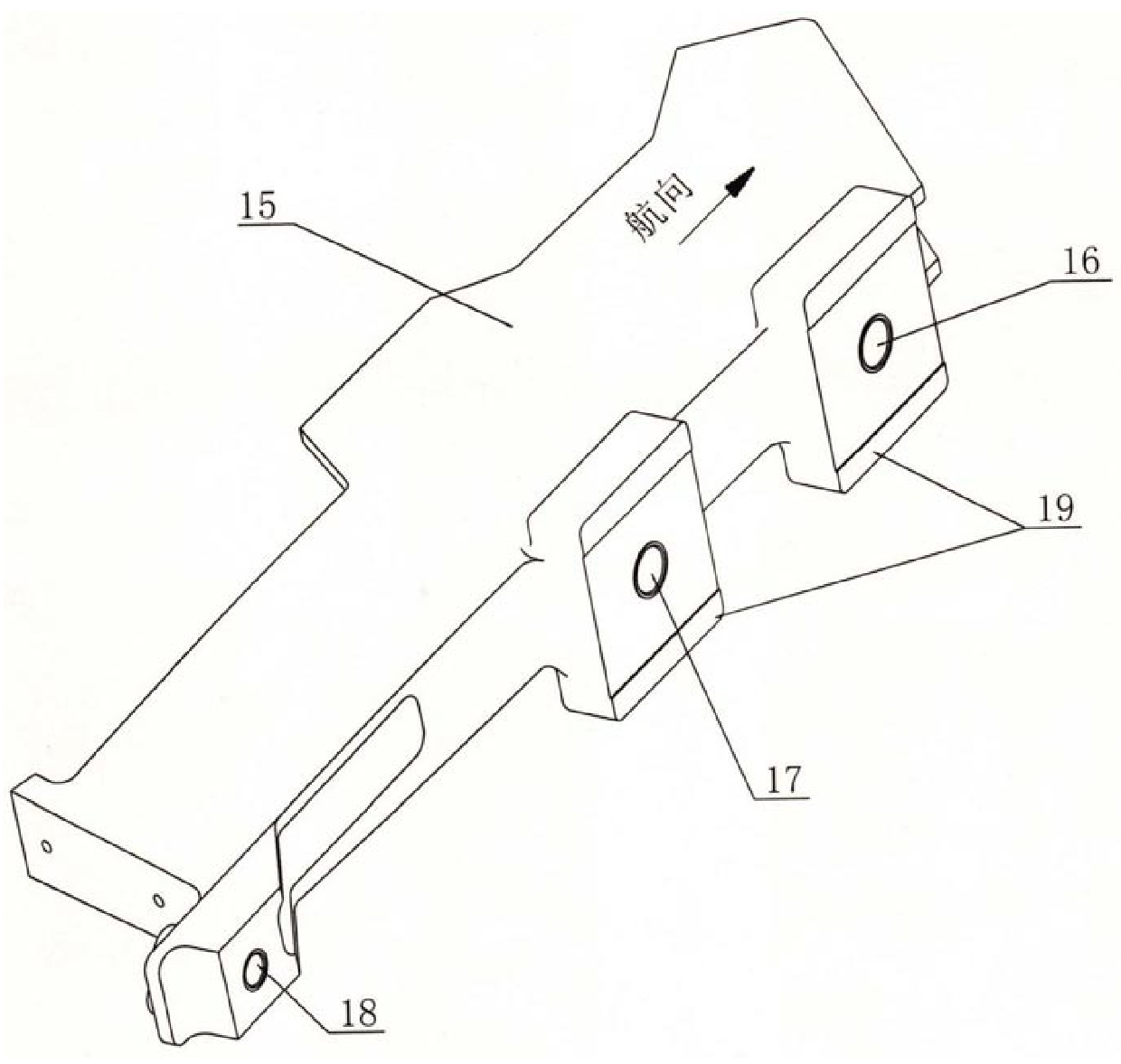

[0029] The trailing edge flap root joint 9 shown in FIG. 1 is depicted in FIG. 4 . The trailing edge flap passes through the root, middle, and tip three

[0031] The aileron root joint is connected with the seventh rib arm of the wing and the control rod. The root joint acts both as a turning rocker arm and

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com