A cable stripping tool

A tool and cable technology, applied in the field of cable stripping tools, can solve the problems of only applicable fixed size and low safety, and achieve the effect of improving stripping efficiency and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

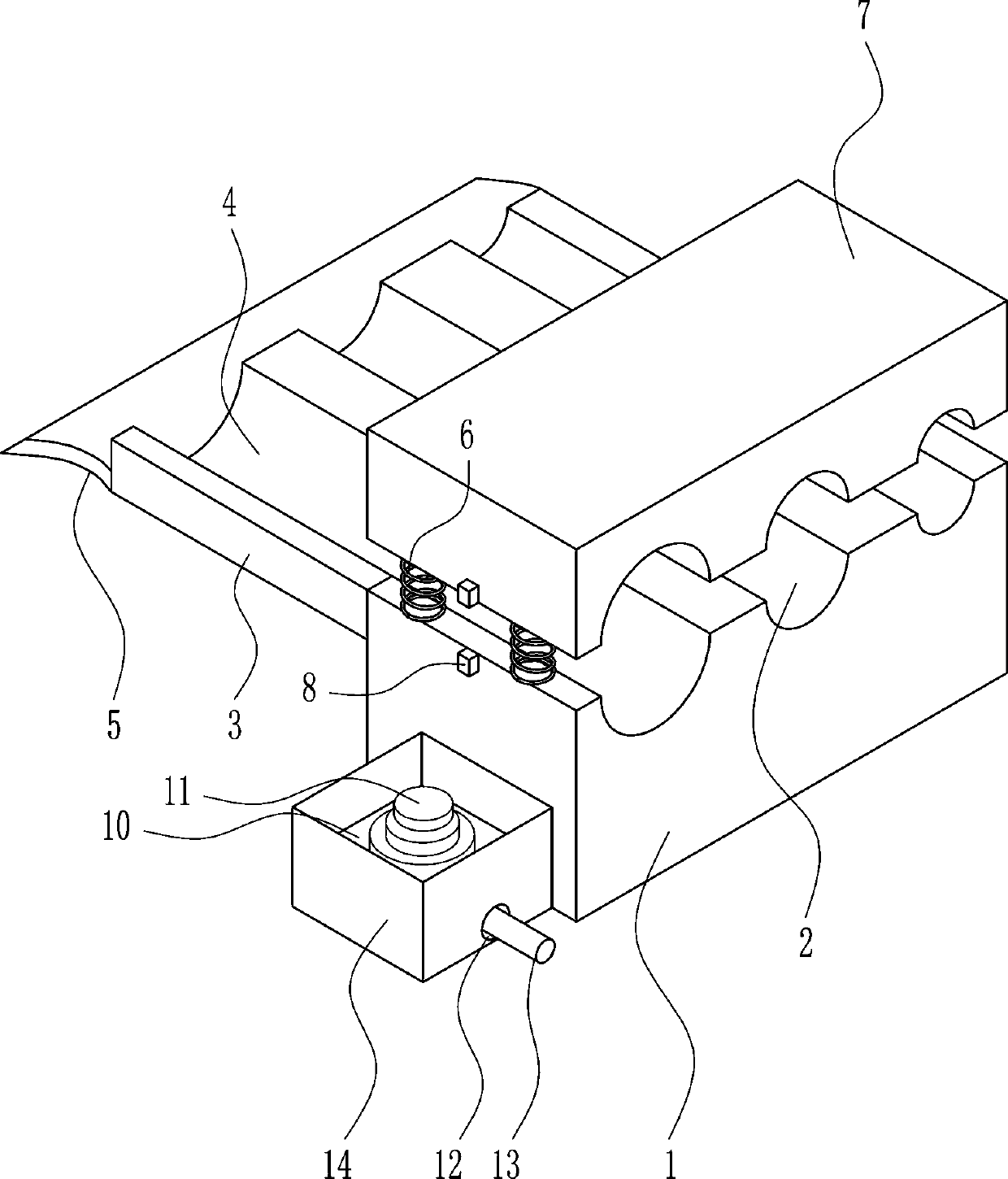

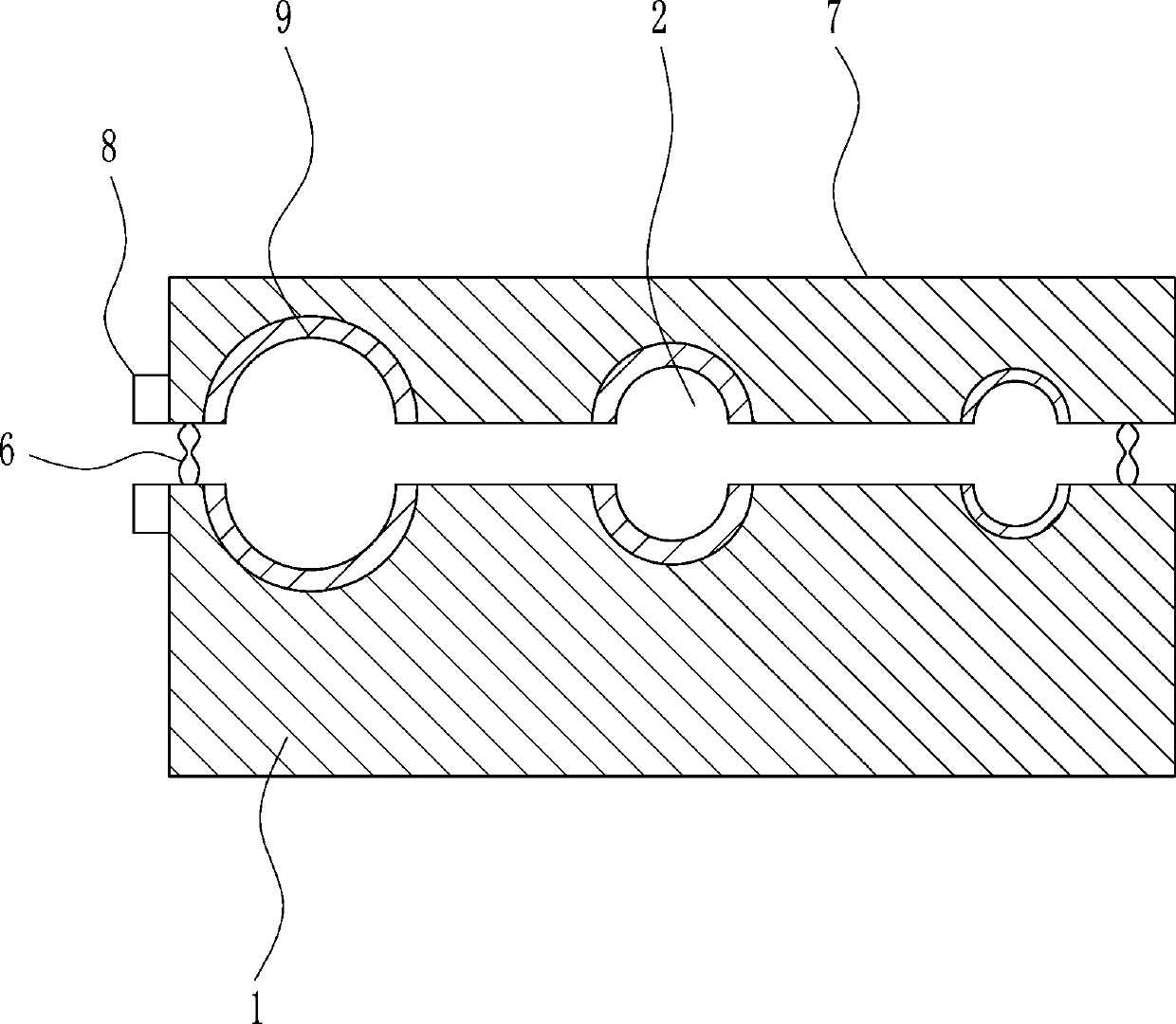

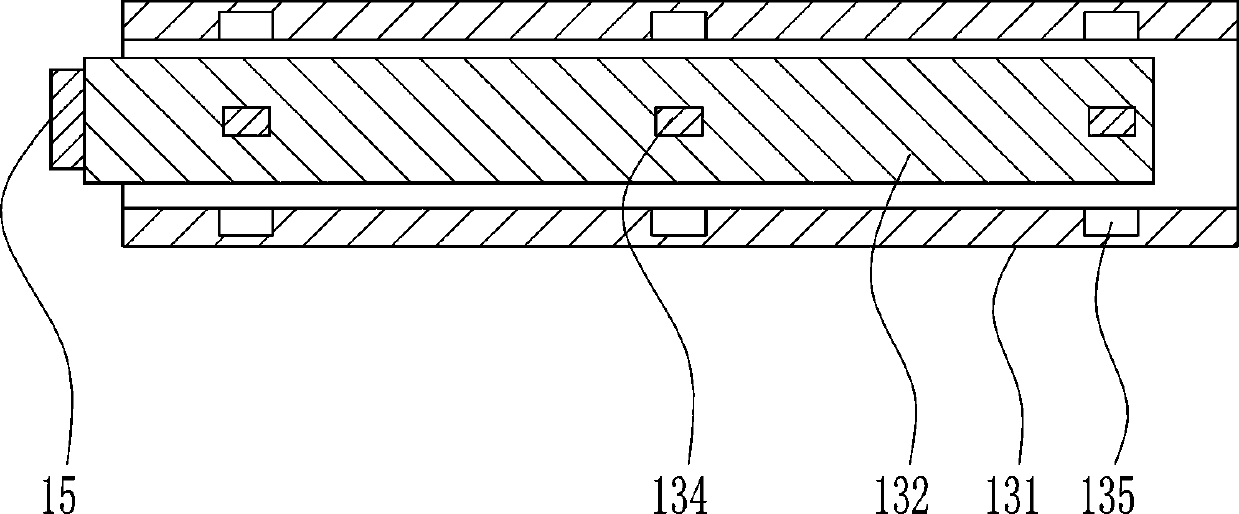

[0033] A cable stripping tool such as Figure 1-7 As shown, it includes a base 1, a placing table 3, an arc plate 5, a spring 6, a pressing table 7, a fixing device 8, and a blade 9. 3 second grooves 4 of different sizes are provided in turn, and the lower part of the rear wall of the placing table 3 is welded with an arc-shaped plate 5, and the left and right sides of the top of the base 1 are provided with springs 6, and the top of the spring 6 is provided with a pressing table 7, and the pressing table 7 The bottom and the top of the base 1 are sequentially provided with three first grooves 2 of different sizes from left to right, the first groove 2 matches the second groove 4, and the first groove 2 is provided with a blade 9, The lower part of the left wall of the press platform 7 and the upper part of the left wall of the base 1 are provided with a matching fixing device 8 .

[0034] The fixing device 8 includes a first block 81, a hinge 82 and a concave block 83, the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com