Method for Determining Effective Drainage Radius Based on Gas Emission Characteristics of Perforated Boreholes

A technology of gas gushing and drilling through layers, which is used in special data processing applications, instruments, design optimization/simulation, etc. Simple and fast, simple process, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

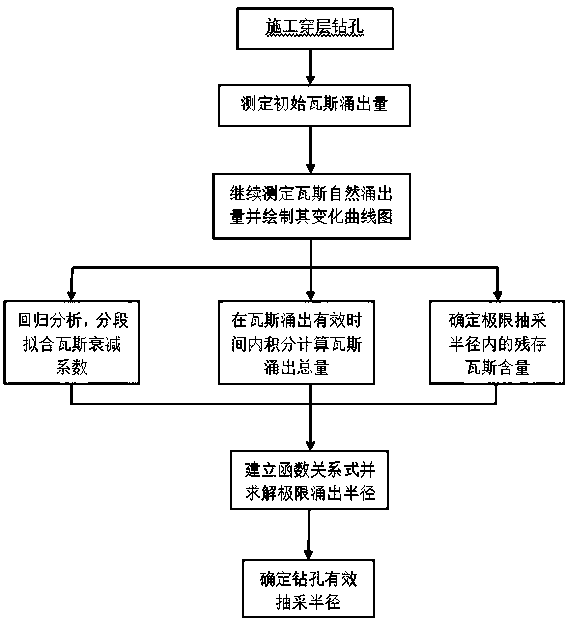

[0025] The method for determining the effective drainage radius based on the gas emission characteristics of the cross-layer drilling of the present invention, such as figure 1 As shown, the following steps are included:

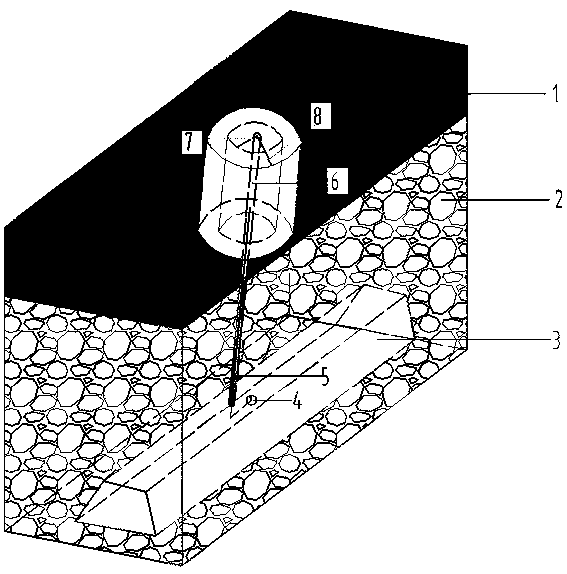

[0026] 1) For the convenience of drilling construction and the accurate observation of gas emission, the floor drainage roadway is selected for upward penetration drilling to ensure that the drilling penetrates the coal body to the overlying rock layer and seals the hole in time;

[0027]2) Measure the initial gas emission from the borehole, continue to measure the natural gas emission from the borehole, and draw the change curve between the total amount of gas emission from the borehole and the effective time of the gas emission based on the test data;

[0028] 3) Combined with the influence of the concentrated stress around the borehole on the gas emission from the borehole, the change curve is analyzed, and the gas emission is divided into two stages affe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com