Power stage fast control prototype platform for motor control algorithm development

A motor control and fast control technology, applied in general control systems, control/regulation systems, instruments, etc., can solve the problem of inability to detect PWM control current effects, inability to simulate strong electrical signals of motor controllers, and inapplicable motor control algorithm simulation Verification and other issues, to achieve the effect of shortening the development cycle, flexible configuration, and complete functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

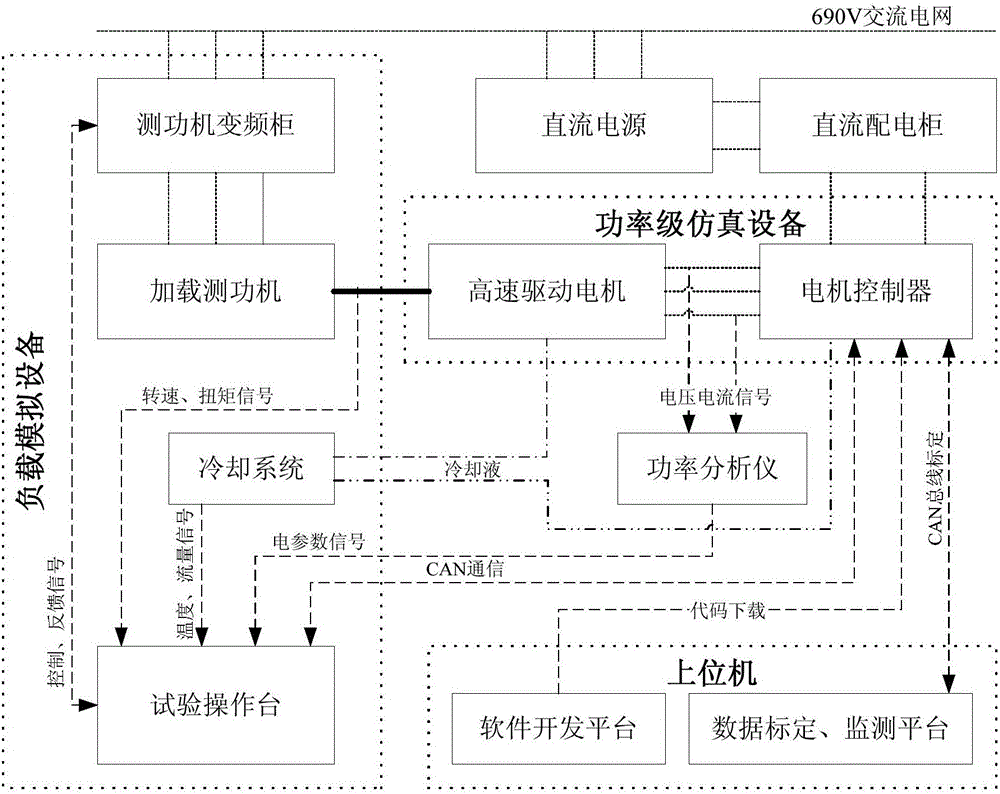

[0057] The technical solution adopted in this embodiment is: a power level rapid control prototype platform for motor control algorithm development, consisting of load simulation equipment, DC power supply and power distribution cabinet, power level simulation equipment, and power analyzer (optional) , host computer, and information exchange channels between functional modules. Load simulation equipment includes dynamometer frequency conversion cabinet, loading dynamometer, mechanical connection equipment, cooling system and test console. Power stage simulation equipment includes high speed drive motors and motor controllers. The upper computer includes a software development platform and a data calibration and monitoring platform. figure 1 A schematic diagram of the overall structure of the power stage rapid control prototype platform for motor control algorithm development proposed by the present invention is shown.

[0058] The connection mode of the platform of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com