True triaxial sand fracturing testing machine and testing method

A technology of sand fracturing and true triaxial, which is applied in the direction of soil material testing and material inspection, which can solve the problems of crushing deformation, inconsistent with the real process, large triaxial pressure difference, etc., and achieve high compression resistance and physiological inertia Effect of small and low viscosity-temperature coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

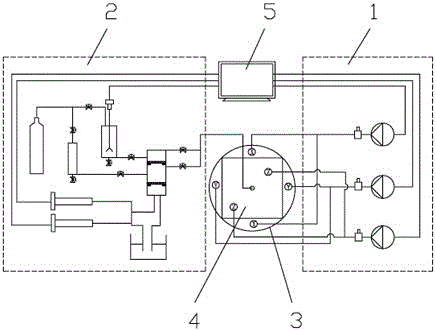

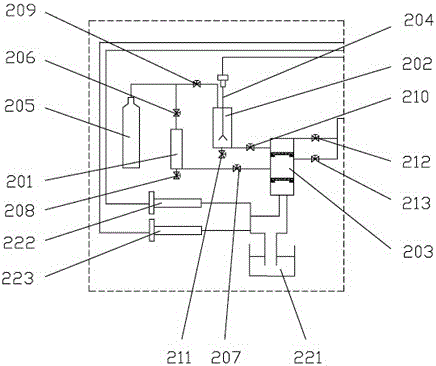

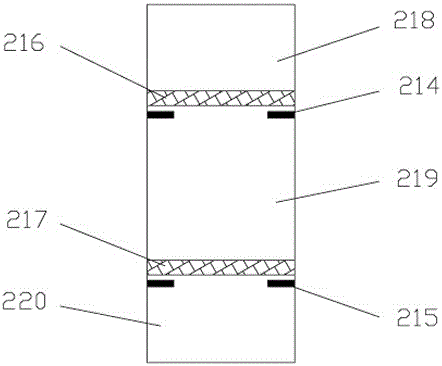

[0048] Such as figure 1 As shown, according to an embodiment of the true triaxial sand fracturing testing machine of the present invention, it includes a confining pressure system 1, an injection system 2 and a true triaxial test frame 3, the confining pressure system 1 and the injection system 2 is connected with the true triaxial test frame 3, and the downhole core 4 is placed in the true triaxial test frame 3; the injection system 2 and the confining pressure system 1 are connected with a computer 5, and the injection system 2 includes pressure Cracking fluid container I 201, fracturing fluid container II 202 and piston container 203, a stirring mechanism 204 is installed in the fracturing fluid container II 202, the stirring mechanism 204 is connected to the computer 5, and a piston plate baffle I 214 is installed in the piston container 203 And the piston plate baffle II 215, the middle parts of the two piston plate baffles are all open.

[0049] The fracturing fluid con...

Embodiment 2

[0069] According to another embodiment of the true triaxial sand fracturing test method of the present invention, the true triaxial sand fracturing test machine used is the same as that of the first embodiment, the test procedure is the same as that of the first embodiment, and the test parameters are different . In this example, the total volume of the pre-fracturing fluid, sand-carrying fracturing fluid and replacement fracturing fluid injected into the downhole core is 800ml, of which the pre-fracturing fluid, sand-carrying fracturing fluid and replacement fracturing fluid The fluids are 40%, 50% and 10% of the total volume respectively, that is, the injected pre-fracturing fluid is 320ml, the sand-carrying fracturing fluid is 400ml, and the replacement fracturing fluid is 80ml.

Embodiment 3

[0071] According to another embodiment of the true triaxial sand fracturing test method of the present invention, the true triaxial sand fracturing test machine used is the same as that of the first embodiment, the test procedure is the same as that of the first embodiment, and the test parameters are different . In this example, the total volume of the pre-fracturing fluid, sand-carrying fracturing fluid and replacement fracturing fluid injected into the downhole core is 600ml, of which the pre-fracturing fluid, sand-carrying fracturing fluid and replacement fracturing fluid The fluids are 40%, 50% and 10% of the total volume respectively, that is, the injected pre-fracturing fluid is 240ml, the sand-carrying fracturing fluid is 300ml, and the replacement fracturing fluid is 60ml.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com