Two-material co-pyrolysis heterogeneous reaction device

A technology of co-pyrolysis and heterogeneous phase, applied in the preparation of test samples, etc., can solve the problem of providing experimental basis, inability to infer co-pyrolysis synergistic mechanism, homogeneous phase, heterogeneous phase, hot volatile matter and semi-coke reaction process And the reaction product is not clear and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

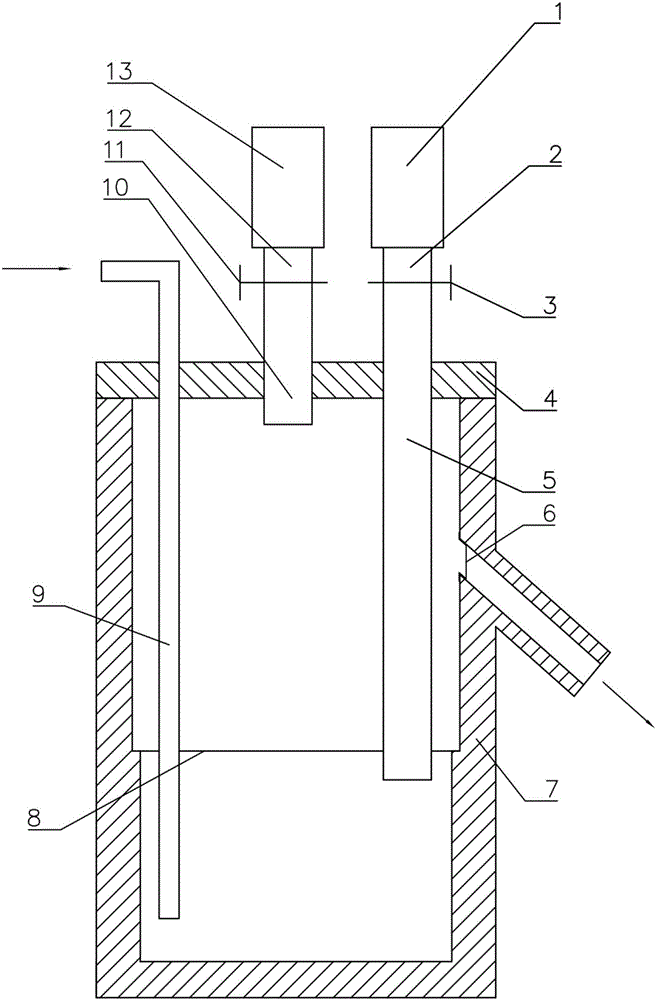

[0019] The following is attached with the manual figure 1 The present invention is described further:

[0020] A device for co-pyrolysis heterogeneous reaction of two materials, comprising a reaction vessel 7, a cover 4, a long standpipe 5, a short standpipe 10 and a stainless steel multi-mesh net 8; the reaction vessel 7 is sealed by a cover 4; The inner side wall of the reaction vessel 7 is provided with a stainless steel multi-mesh net 8; the stainless steel multi-mesh net 8 divides the reaction vessel 7 into upper and lower parts; one end of the long vertical pipe 5 passes through the cover 4 and extends out of the stainless steel multi-mesh Net 8; the other end of the long vertical pipe 5 is equipped with a first feeding sealing cover 1; the long vertical pipe 5 between the first feeding sealing cover 1 and the cover 4 is provided with a first valve switch 3; One end of the short standpipe 10 passes through the cover 4; the other end of the short standpipe 10 is equipped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com