A Method for Analyzing and Suppressing Rotor Vibration Noise of Active Semi-Strapdown Inertial Measurement System

An inertial measurement and rotor vibration technology, which is used in weapon accessories, ammunition testing, ammunition and other directions, can solve problems such as the reduction of measurement accuracy, and achieve the effect of improving measurement accuracy, improving attitude calculation accuracy, and solving the reduction of measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A method for analyzing and suppressing rotor vibration and noise of an active semi-strapdown inertial measurement system, the method is realized by the following steps:

[0017] Step S1: When the active semi-strapdown inertial measurement system is running, use the hardware circuit to collect the specific force data output by the system's Y-axis accelerometer, the specific force data output by the Z-axis accelerometer, and the relative rotation angle data output by the photoelectric encoder ;

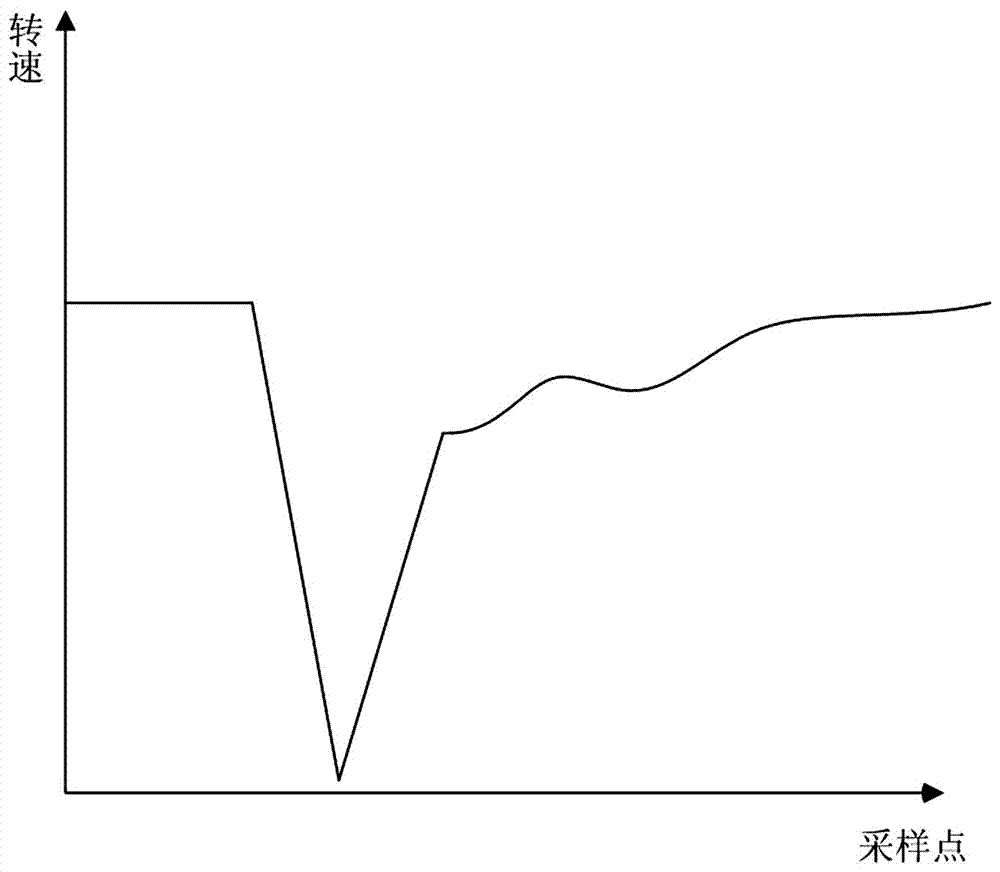

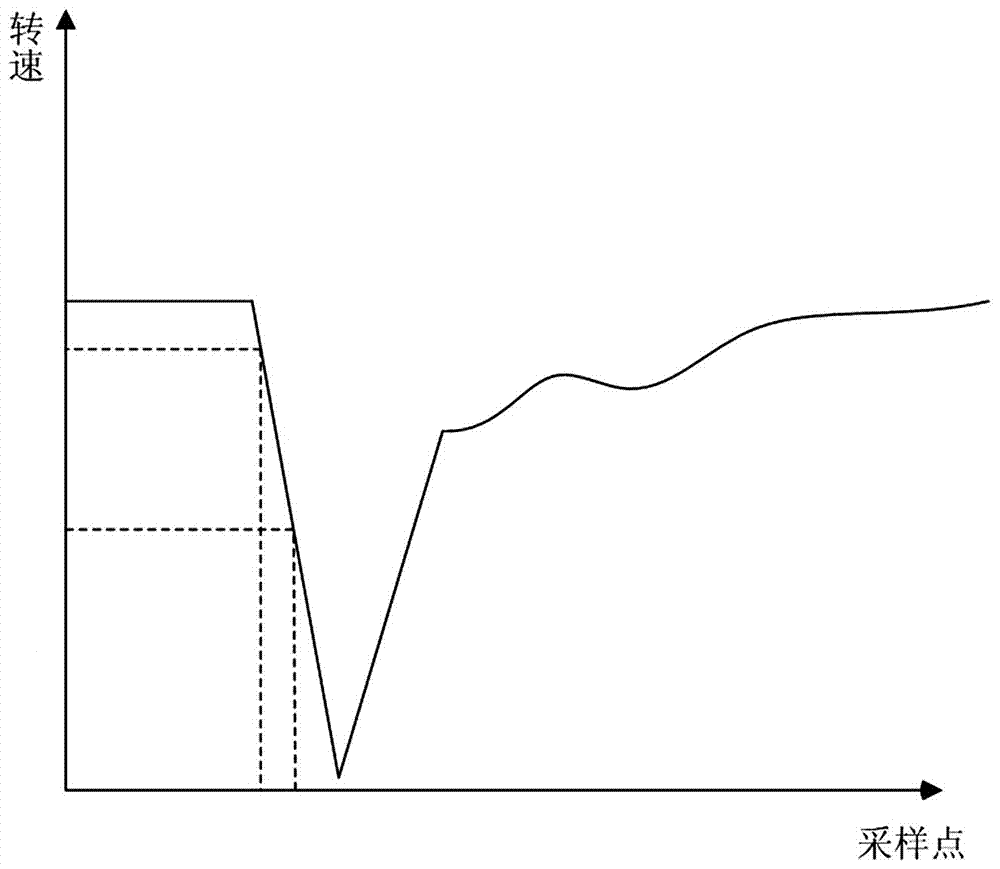

[0018] Step S2: Differentiate the relative rotation angle data output by the photoelectric encoder, thereby obtaining the motor speed data of the system;

[0019] Step S3: Set the initial time interval to 1s, and segment the motor speed data with the initial time interval, thereby obtaining several motor speed data segments; then adjust the time interval until the maximum motor speed in each motor speed data segment is less than twice the minimum motor speed, record the data poi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com