Reciprocating type magnetic liquid self-circulating lubrication sealing device

A magnetic liquid and sealing device technology, which is applied in the direction of engine sealing, engine lubrication, engine components, etc., can solve problems such as safety threats, missing devices, and malfunctioning staff, so as to improve service life, reduce and prevent leakage, The effect of reducing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

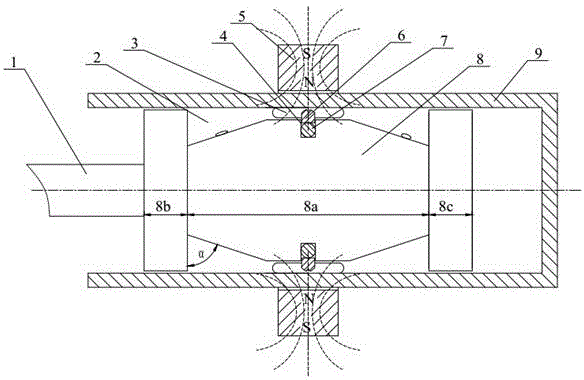

[0034] like figure 1 As shown, a reciprocating magnetic liquid self-circulating lubrication sealing device includes a piston shaft 1, a magnetic liquid lubricant 3, a ring magnet 5, a piston 8 and a cylinder 9;

[0035] The piston 8 includes a piston middle part 8a, a piston end part I8b and a piston end part II8c; the piston middle part 8a is spindle-shaped, and the middle section has the largest diameter and is cylindrical in shape, and the middle section accounts for 30% of the total length of the piston middle part 8a, extending to both ends of the piston middle part 8a The diameter gradually decreases; the two ends of the middle part of the piston 8a are respectively connected with the piston end I8b and the piston end II8c, and the connection forms an angle α of 70°; the piston end I8b is connected with the piston shaft 1;

[0036] The piston 8 is placed inside the cylinder 9, and the inner diameter of the cylinder 9 is 16mm. There is a 2.65×2.65mm annular groove 4 in t...

Embodiment 2

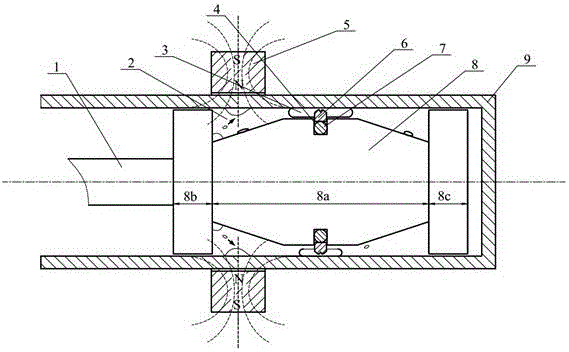

[0039] With reference to the structure of embodiment 1, the difference between the present embodiment and embodiment 1 is that the section of the ring magnet 5 is an isosceles triangle with an apex angle of 120°, the magnetic field strength in the middle of the magnet is greater than that on both sides, and the scattered magnetic liquid lubricant 3 droplets are captured by the magnet. After capture, snap to the center from both sides, such as Figure 4 shown.

Embodiment 3

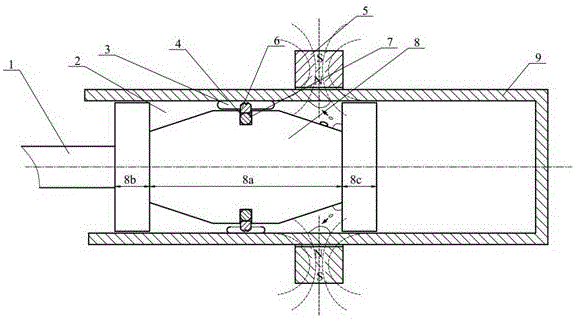

[0041] Referring to the structure of Embodiment 1, the difference between this embodiment and Embodiment 1 is that the angle α between the middle part of the piston 8a and the connection between the piston end I8b and the piston end II8c is 45°, and the piston end I8b and the piston end II8c are close to the gap 2 One side protrudes to form a sharp corner, such as Figure 5 As shown, reducing the angle α can prevent lubricant leakage more effectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com