Bearing device for fixed length moving cutting of textile fabric

A bearing device and textile fabric technology, applied in the direction of mechanical devices, textile material cutting, measuring devices, etc., can solve the problems of many people, inconvenient measurement, laborious moving process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

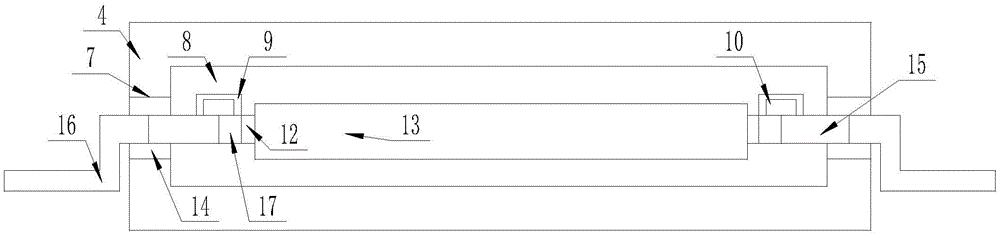

[0020] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4As shown, a carrying device for fixed-length mobile cutting of textile cloth, comprising a strip-shaped carrying base (1), the upper surface of the strip-shaped carrying base (1) is fixedly connected by a strip-shaped hollow shell (2) , the upper surface of the strip-shaped hollow shell (2) has a No. 1 semicircular through groove (3), and the No. 1 semicircular through groove (3) is embedded with a No. 1 semicircular coverless shell ( 4), one end of the upper surface of the No. 1 semicircular coverless housing (4) is provided with a plurality of No. 1 rotating shafts (5), and the plurality of No. 1 rotating round shafts (5) are sleeved with a The No. 2 semicircular bottomless casing (6) matching the No. 1 semicircular bottomless casing (4), the No. 1 semicircular bottomless casing (4) is provided with a bearing mechanism, and The front surface of the shaped hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com