Carbon nanotube/polyaniline composite material with electrochemical anticorrosion effect, preparation method and application

A carbon nanotube and composite material technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of difficult dispersibility, difficult anti-corrosion application, etc., and achieve the effects of excellent anti-corrosion performance, excellent electrochemical anti-corrosion effect, and good dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Preparation of carbon nanotube / polyaniline composite materials:

[0031] Weigh 0.116g of carbon nanotubes, 0.93g of aniline and 0.10g of emulsifier 2A-1 and disperse them in 80mL of distilled water, transfer them to a 250mL three-neck flask, and stir ultrasonically for 60min. Then add 0.4g H 2 SO 4 , adjust the pH of the system to 1, continue ultrasonic stirring for 15 min and move to ice bath conditions.

[0032] Weigh 2.28g of initiator ammonium sulfate (APS) and dissolve it in 20mL of 0.05mol / L sulfuric acid aqueous solution, transfer it to a constant pressure dropping funnel, and slowly add it dropwise to the above mixing system for 40 minutes. The in-situ oxidative polymerization reaction was carried out for 6 hours under the condition of ice bath at 0-4°C.

[0033] After the reaction, the solid-phase product was washed with ethanol and deionized water, and finally vacuum-dried and ground at 80°C to obtain a carbon nanotube / polyaniline composite material (C-P...

Embodiment 2

[0041] 1. Preparation of carbon nanotube / polyaniline composite materials:

[0042] Weigh 0.116g of carbon nanotubes, 0.464g of aniline and 0.058g of emulsifier 2A-1 and disperse them in 80mL of distilled water, transfer them to a 250mL three-neck flask, and stir ultrasonically for 60min. Then add 0.4g H 2 SO 4 , adjust the pH of the system to 2, continue ultrasonic stirring for 15 min and move to ice bath conditions.

[0043] Weigh 2.28g of initiator APS and dissolve it in 20mL of 0.05mol / L sulfuric acid aqueous solution, transfer it to a constant pressure dropping funnel, and slowly add it dropwise to the above mixing system for 40min. React for 6 hours under the condition of ice bath at 0~4℃.

[0044] After the reaction, the product was washed with ethanol and deionized water, and finally vacuum-dried and ground at 80°C to obtain a carbon nanotube / polyaniline composite (C-PANI 2).

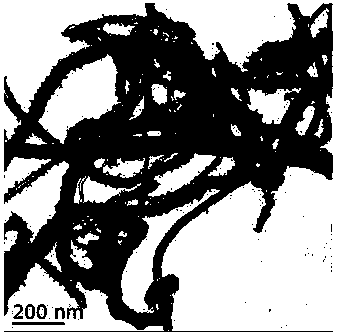

[0045] The transmission electron microscope image of the composite material made in this ...

Embodiment 3

[0049] 1. Preparation of carbon nanotube / polyaniline composite materials:

[0050] Weigh 0.116g of carbon nanotubes, 0.232g of aniline and 0.035g of emulsifier 2A-1 and disperse them in 80mL of distilled water, transfer them to a 250ml three-neck flask, and stir ultrasonically for 60min. Then add 0.4g H 2 SO 4 , adjust the pH of the system to 1, continue ultrasonic stirring for 15 min and move to ice bath conditions.

[0051] Weigh 2.28g of initiator APS and dissolve it in 20mL of 0.05mol / L sulfuric acid aqueous solution, transfer it to a constant pressure dropping funnel, and slowly add it dropwise to the above mixing system for 40min. React for 6 hours under the condition of ice bath at 0~4℃.

[0052] After the reaction, the product was washed with ethanol and deionized water, and finally vacuum-dried and ground at 80°C to obtain a carbon nanotube / polyaniline composite material (C-PANI 3).

[0053] The transmission electron microscope image of the composite material made...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com