Continuous preparation method for bisphenol A-di(diphenyl phosphate)

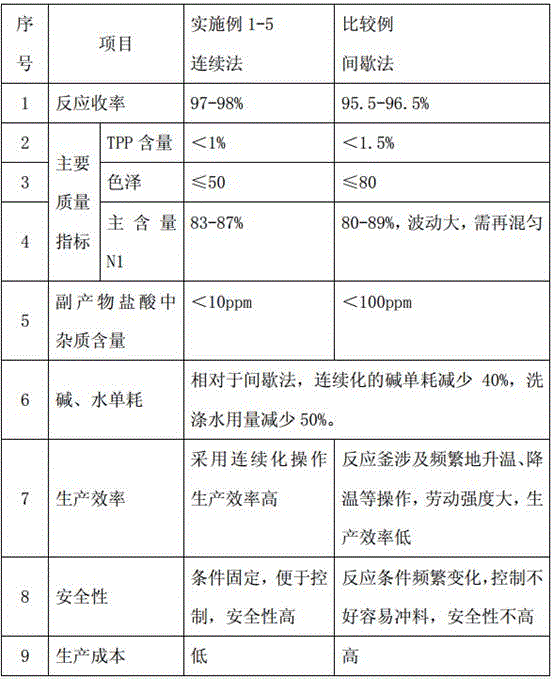

A technology of diphenyl phosphate and bisphenol, which is applied in the field of continuous preparation of bisphenol A-bis(diphenyl phosphate), can solve the problem that the product quality and yield are difficult to meet the process requirements, increase equipment investment and maintenance Costs, inability to achieve product quality and other issues, to achieve the effect of solving the difficulty of solid feeding, solving the problem of air tightness of the device, and improving product yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation of embodiment 1 BDP, its technological process is as figure 1 As shown, the specific steps are as follows:

[0031] 1. Continuous multi-stage cross-linking reaction process:

[0032] Put 2000Kg / h of phosphorus oxychloride into the premixing tank, recover 2500Kg / h of phosphorus oxychloride, and 15Kg / h of magnesium chloride, and then heat the mixed phosphorus oxychloride to 90-100°C by pump pressurization , at the same time, bisphenol A1500kg / h is continuously fed in proportion, and the cross-linking reaction is carried out in the first-stage cross-linking reactor: the reaction material passes through the bottom of the tank, pressurized by a pump, and goes to the gas-liquid separator tower and condenser to realize gas-liquid separation and condensation. Phosphorus oxychloride returned to the kettle. The reaction temperature in the kettle is 95-100°C, and the reaction material is transferred to the subsequent reactor for heat preservation by using the poten...

Embodiment 2

[0047] Substantially the same as Example 1, but remove the capping reaction and add magnesium chloride 10Kg / h, and the residence time of each reactor material is 3 hours. Other things remain unchanged, the final finished product is 4266.5kg / h, and the product yield is 96.80%. Product color 35, TPP content 0.86%, main content N 1 84.7% (HPLC).

Embodiment 3

[0049] It is basically the same as Example 1, but the amount of phosphorus oxychloride is changed to 5500kg / h, the amount of phenol in the continuous capping reaction process is changed to 2380kg, and 10Kg of added magnesium chloride is removed. Other things remain unchanged, the final finished product is 4288.49kg / h, and the product yield is 97.3%. Product color 35, TPP content 0.78%, main content N 1 87.4% (HPLC).

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com