Multifunctional coating barrel

A paint bucket, multi-functional technology, applied in unloading devices, containers, lighting and heating equipment, etc., can solve problems affecting paint characteristics, pits on the outer surface of paint buckets, economic losses, etc., to improve thermal insulation performance, The effect of saving working time and saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

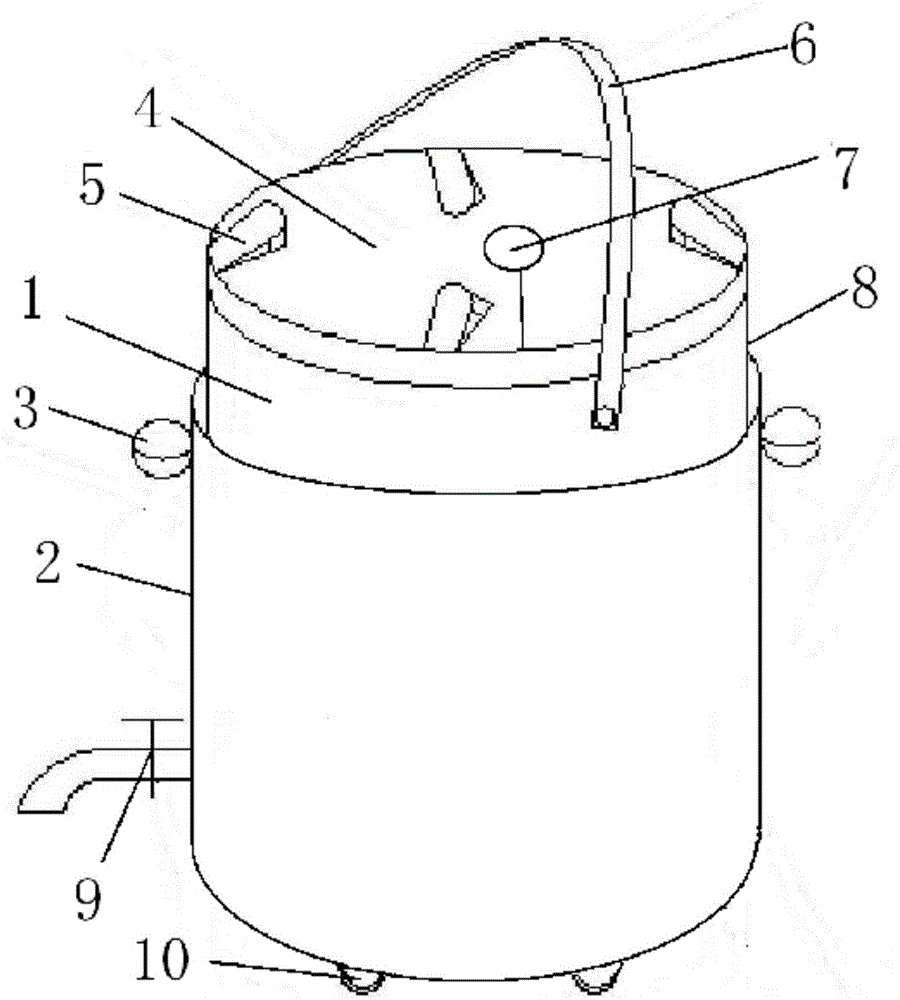

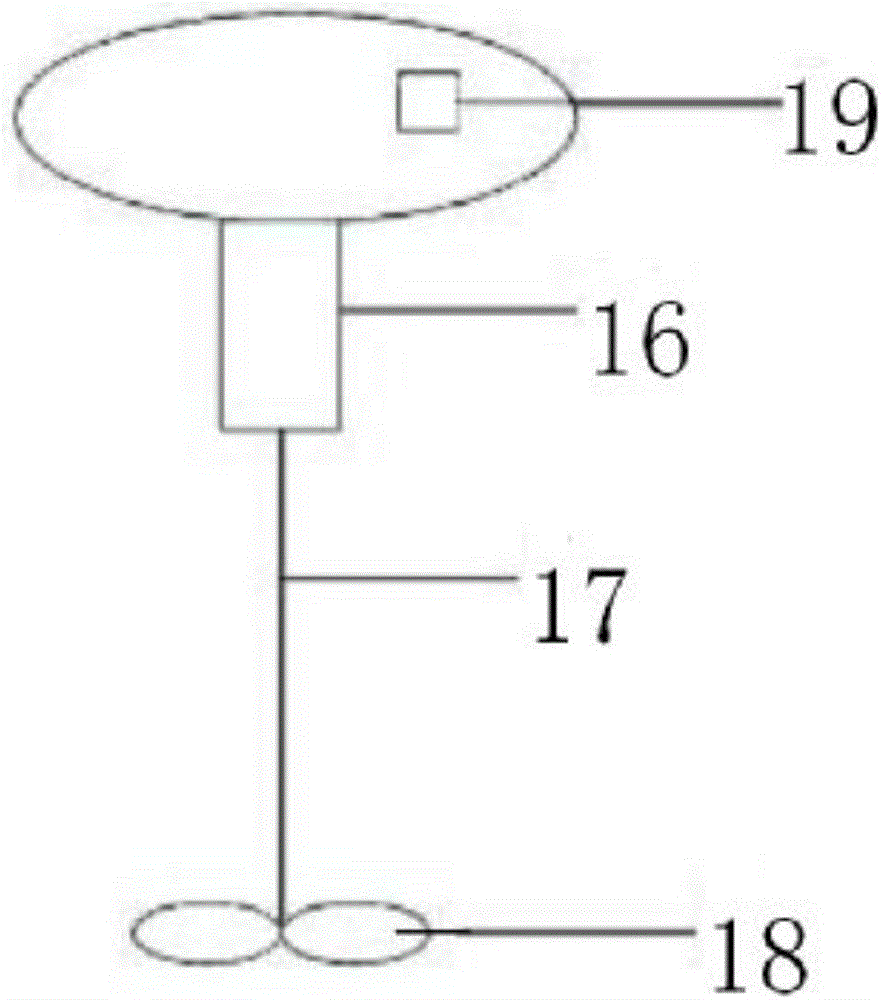

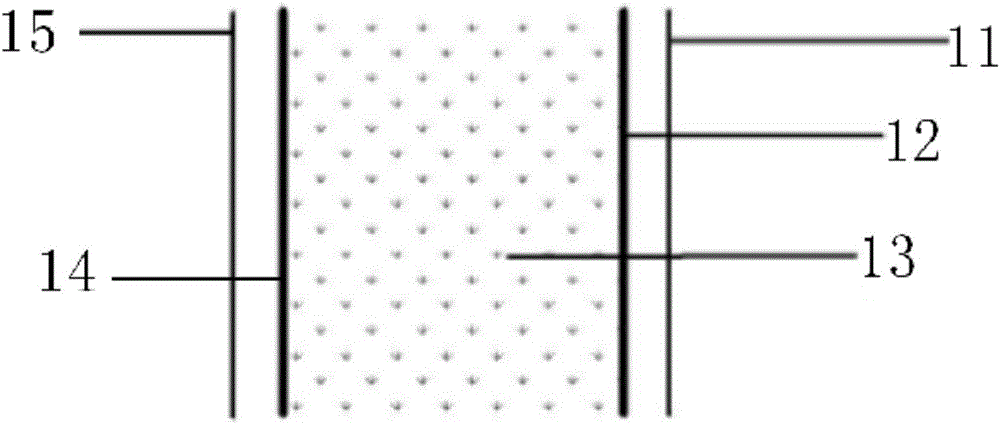

[0023] see figure 1 As shown, a multi-functional paint barrel of the present invention includes a barrel body 1, and the outer cover of the barrel body is provided with a protective cover 2 made of rubber, the size of the protective cover is adapted to the size of the barrel body, and the protective cover is It is a hollow cylinder with one end open and one end closed. The outer surface of the protective sleeve is provided with elastic protrusions 3 near the lid, and the lid 4 at the top of the cylinder is evenly equipped with a plurality of protective protrusions made of rubber. 5. The barrel cover is provided with paint bucket handles 6 and a stirring and mixing device 7, and the outer wall of the barrel is provided with an insulating layer 8; the barrel body is provided with a discharge valve 9 near the bottom, and the barrel body The bottom is provided with a roller 10; the elastic protrusion is spherical or ellipsoidal; the protective protrusion is a gradual change in lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com