Rapid and simple frame alignment device for silk screen frame

A technology of screen frame and screen, applied in screen printing, screen printing machine, printing and other directions, can solve problems such as poor adjustment effect, and achieve the effect of high accuracy, wide adjustment range and enlarged adjustment range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

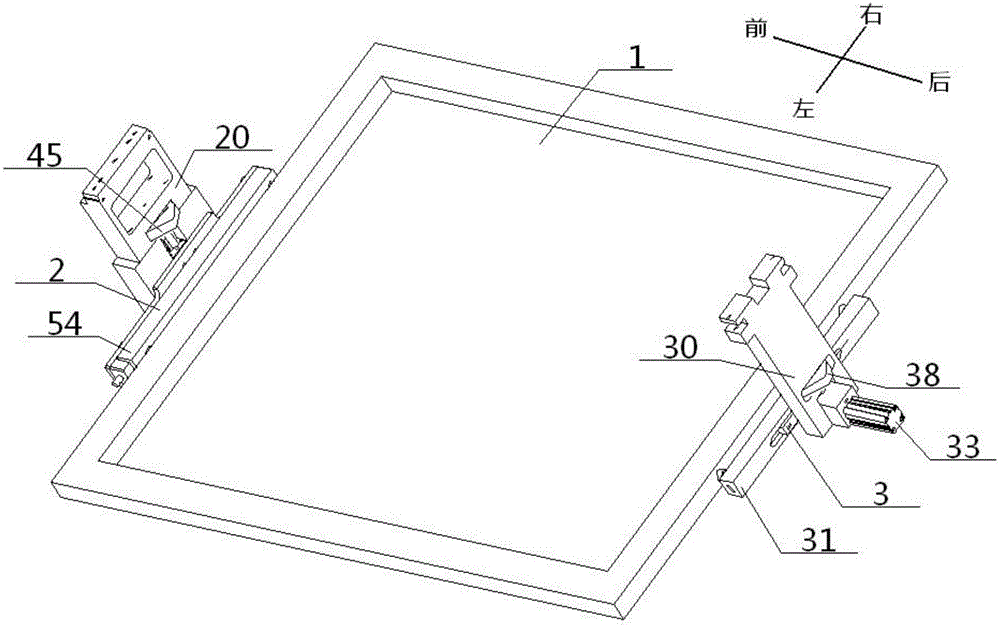

[0061] see Figure 1 to Figure 11 , a fast and simple frame alignment device for a screen frame of a screen, comprising a forearm clamping mechanism 2, a screen frame 1 of a screen and a clamping mechanism 3 of a rear arm, the screen frame 1 of the screen is arranged horizontally, and the screen frame 1 of the screen The front side of the screen frame 1 is connected with the forearm clamping mechanism 2, and the rear side of the screen frame 1 is connected with the rear arm clamping mechanism 3;

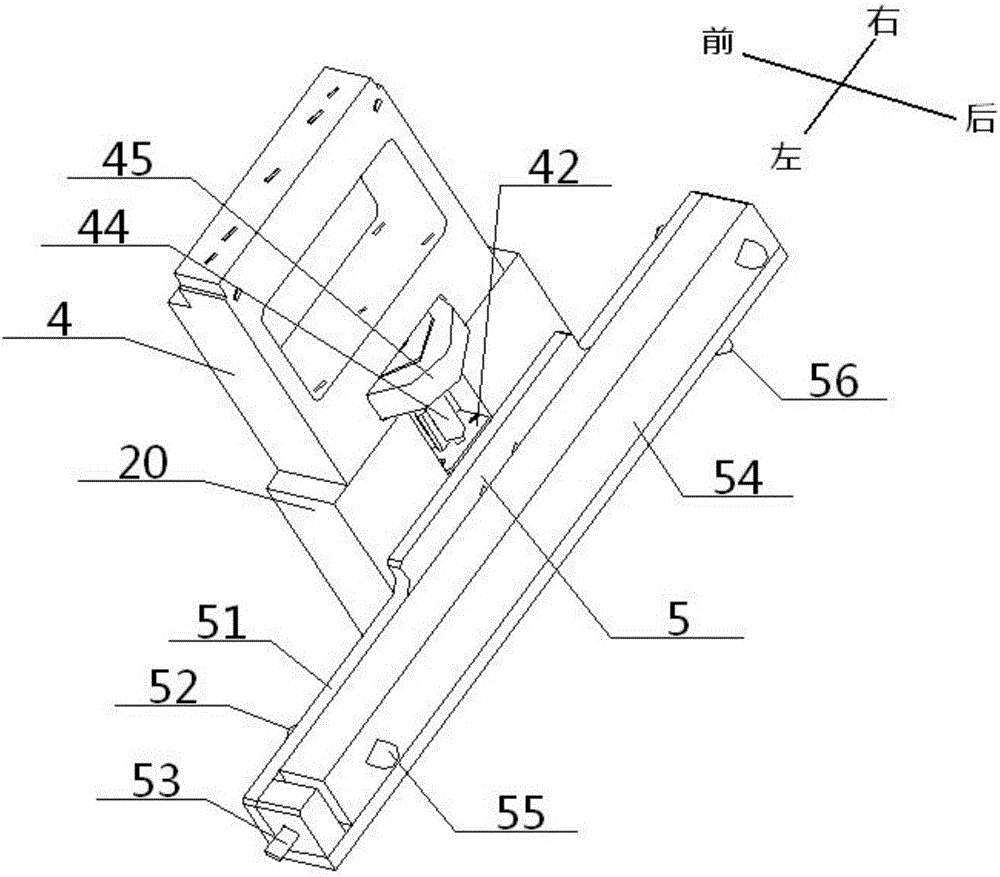

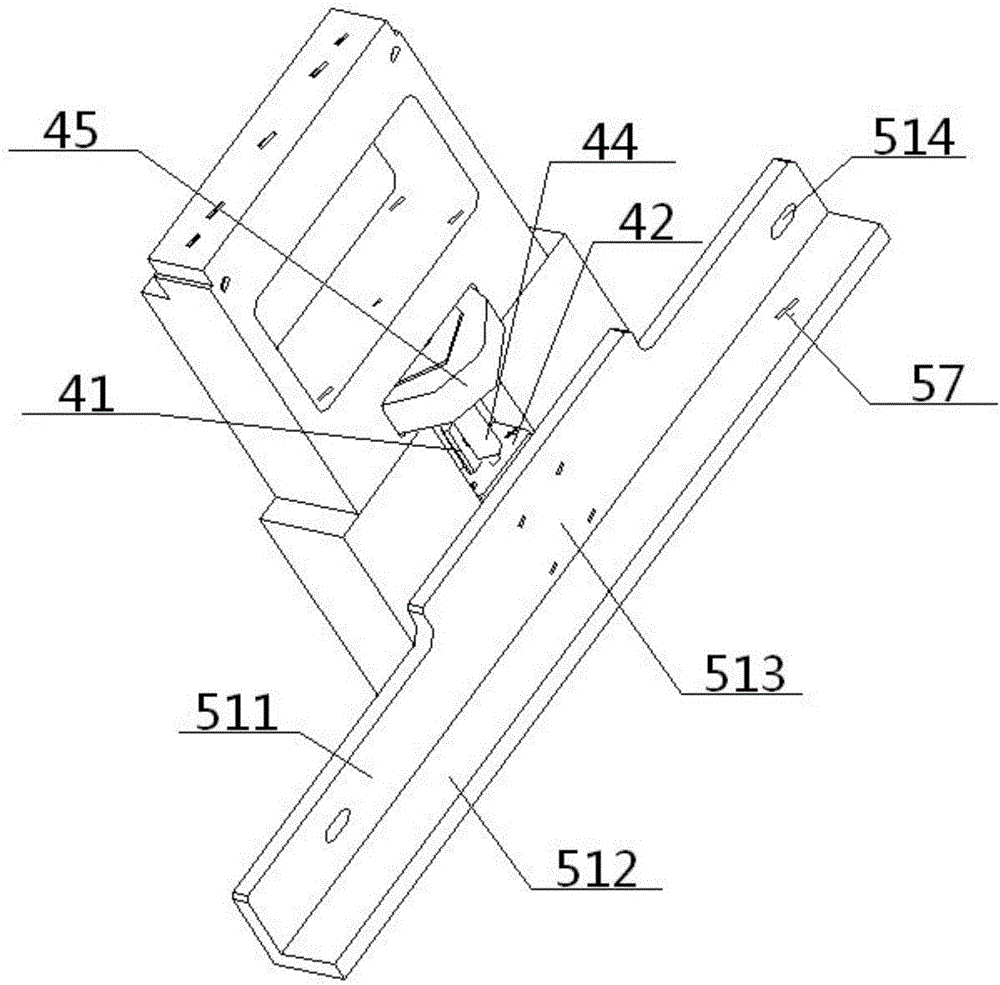

[0062] The forearm clamping mechanism 2 includes a vertical adjustment part 4 and a horizontal adjustment part 5; the horizontal adjustment part 5 includes a bracket 51, a front and rear adjustment rod 52, a left and right adjustment rod 53 and a left and right adjustment slider 54. Bracket 51 is an L-shaped structure. Bracket 51 includes a vertical plate 511 and a horizontal plate 512 that are vertically connected to each other. A front and rear adjustment hole 514 corresponding to...

Embodiment 2

[0064] Basic content is the same as embodiment 1, the difference is:

[0065] The bottom of the left and right adjusting sliders 54 near its right end is connected to one end of the positioning bottom pin 56, and the other end of the positioning bottom pin 56 passes through the track hole 57 provided on the horizontal plate 512 and extends to the bottom of the bracket 51. Externally, the raceway hole 57 is arranged near the right end of the horizontal plate 512 , and the diameter of the raceway hole 57 is larger than the diameter of the positioning bottom pin 56 .

Embodiment 3

[0067] Basic content is the same as embodiment 1, the difference is:

[0068] The vertical direction adjustment part 4 includes a vertical guide rail 41, a vertical cylinder 42 and a vertical base 43, the vertical guide rail 41 passes through the inside of the vertical cylinder 42, the bottom of the vertical guide rail 41 is connected with the vertical base 43, and the vertical cylinder 42 The side is connected with the back connecting portion 513 on the vertical plate 511 , and the vertical cylinder 42 is slidably fitted along the vertical guide rail 41 . The top of the vertical cylinder 42 is connected with the front adjusting disc 45 through the front fine adjustment rod 44 , and the front adjusting disc 45 is arranged higher than the vertical guide rail 41 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com