Pre-positioning tightening mechanism for arc tenon tooth blades

A positioning mechanism and pre-positioning technology, applied in positioning devices, metal processing machinery parts, clamping, etc., can solve the problems of low machining accuracy of blade roots and inconsistent positioning references

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

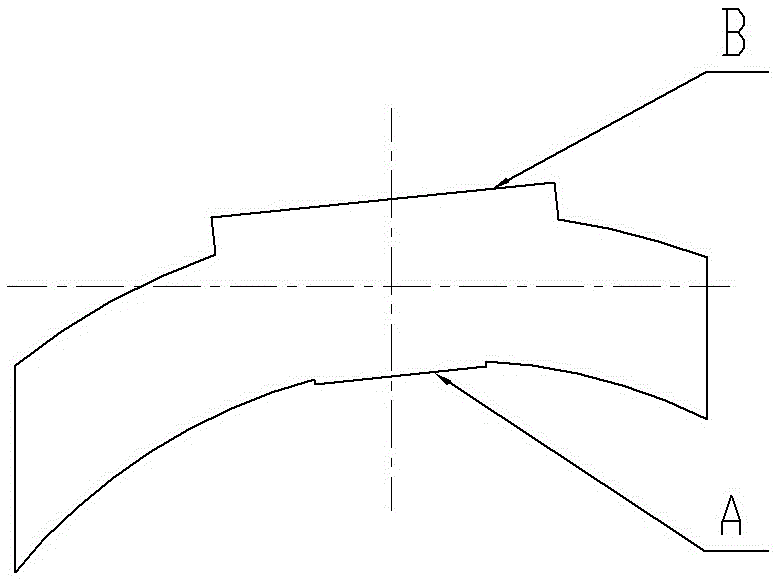

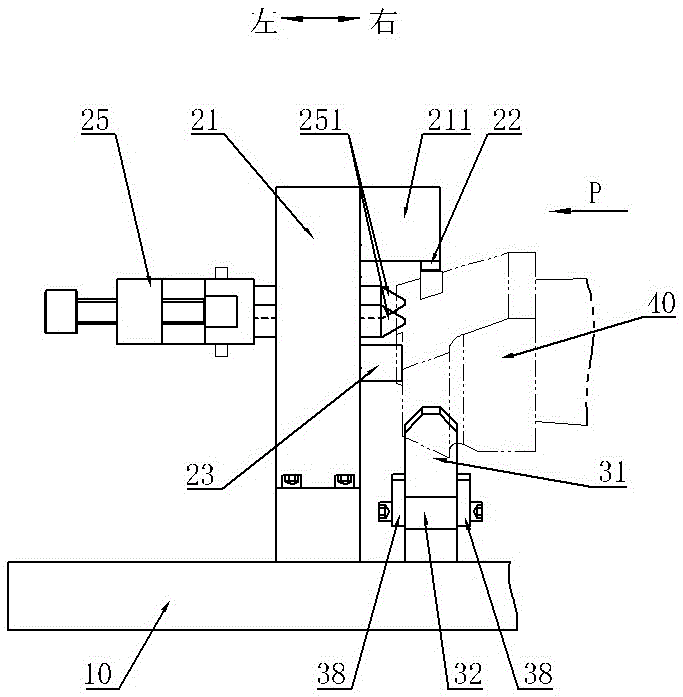

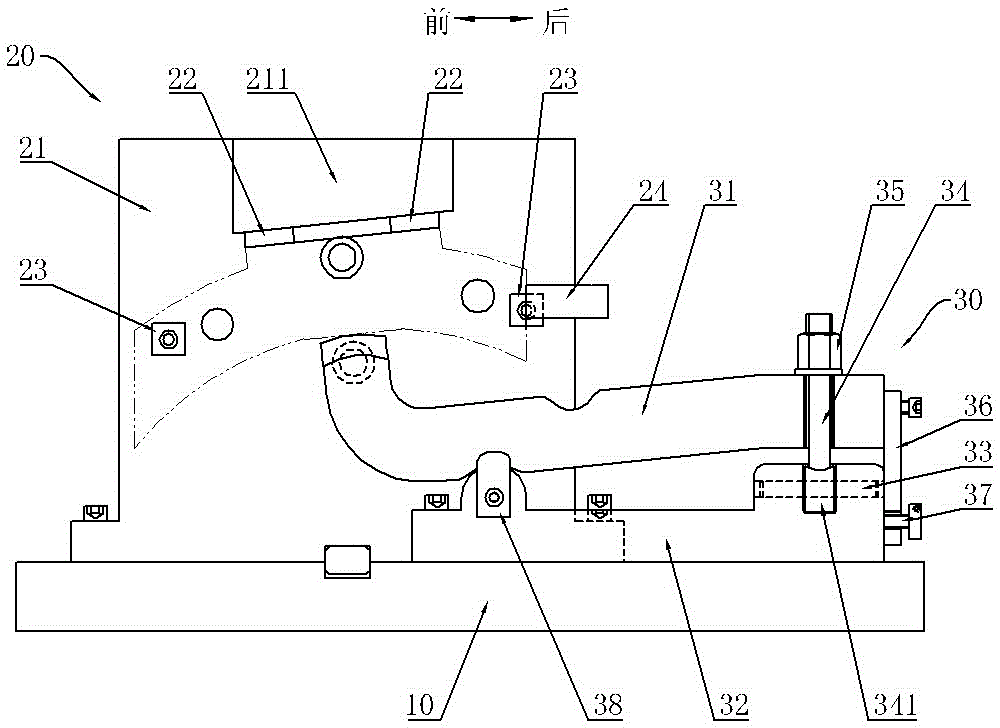

[0023] See figure 2 and image 3 The mechanism of the present invention includes a base plate 10, on which a positioning mechanism 20 and a tightening mechanism 30 are installed, wherein the positioning mechanism 20 includes a positioning seat 21, and the top of the positioning seat 21 is provided with a right convex portion 211, and the bottom surface of the right convex portion 21 is fixed. Equipped with a positioning support plate 22 for positioning the arc-shaped mortise blade root back craft B, the clamping mechanism 30 includes a clamping lever 31 and a clamping seat 32, and the clamping lever 31 is rotatably supported on the clamping seat 32, the top tight seat 32 is fixedly mounted on the base plate 10 and is located below the right convex portion 211 of the positioning seat 21, and the front end of the top tight lever 31 is provided with an upturned and curved top tight portion 311, and the rear end can be aligned with the top tight seat. 32 is locked and connected,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com