Cleaning flexible shaft and pipeline cleaning system and method

A cleaning system and flexible shaft technology, applied in cleaning methods and utensils, chemical instruments and methods, and smoke and dust removal, etc., can solve the problems of low cleaning efficiency and single function of air-conditioning pipes, and achieve the goal of reducing air pressure impulse and slowing inhalation rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Embodiments of the present invention will be described in detail below.

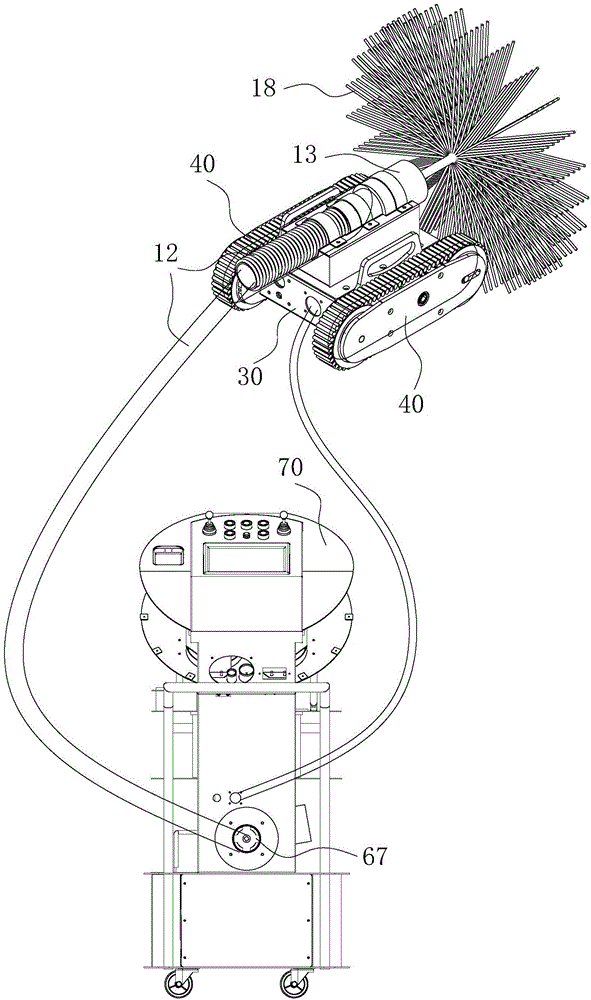

[0048] Such as Figure 1 to Figure 11 As shown, the pipeline cleaning system includes a seat body 30, a traveling mechanism 40, a control terminal and a cleaning flexible shaft,

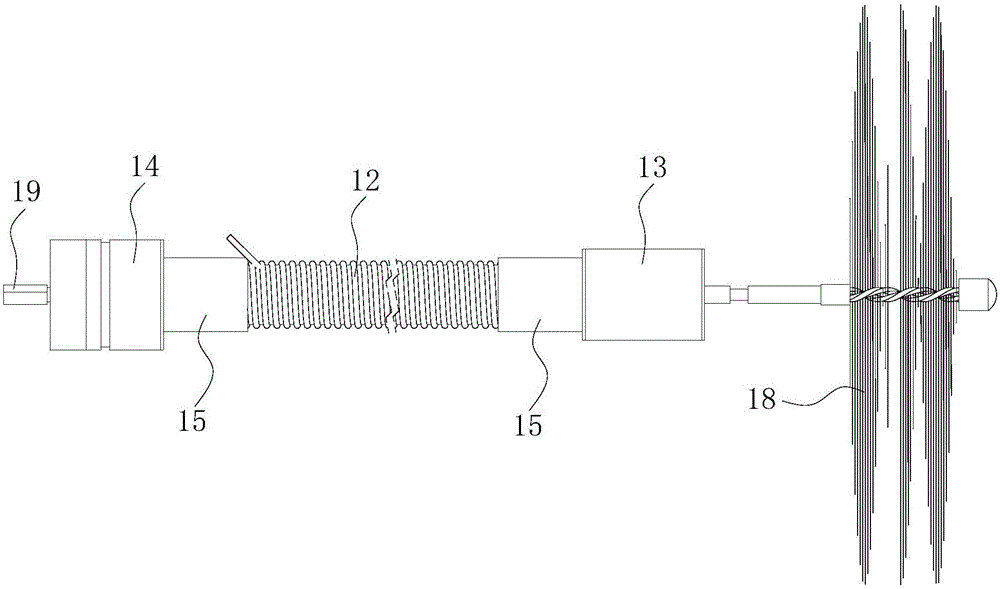

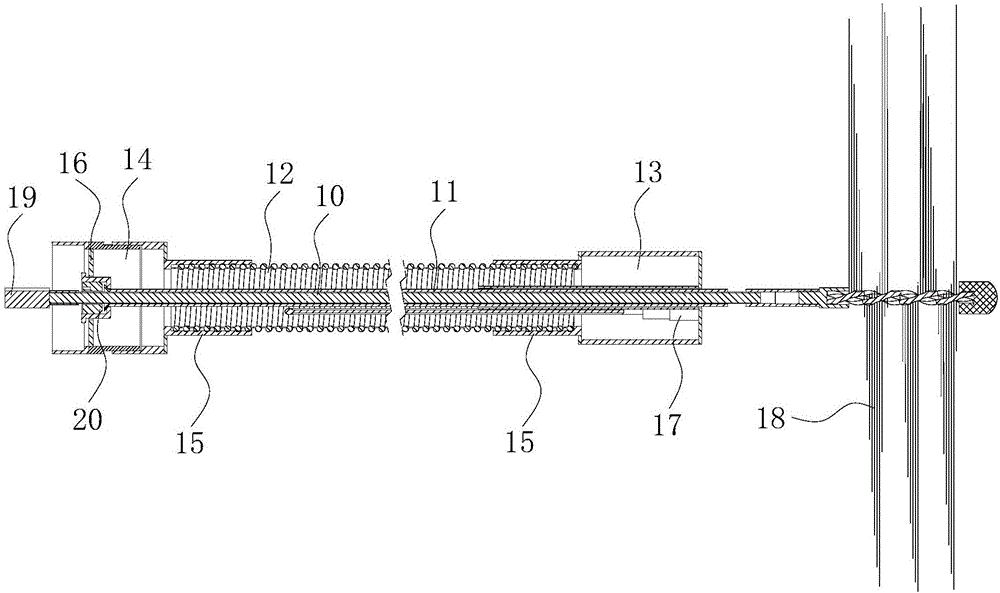

[0049] Clean the flexible shaft, including the flexible shaft shaft core 10, the shaft core sleeve 11, the ventilation pipe 12, the dust suction end piece 13 and the connecting piece 14, the shaft core sleeve 11 is sleeved on the flexible shaft shaft core 10; 12 sets of ventilation pipes Set on the shaft core sleeve 11, there is a gap between the ventilation pipe 12 and the shaft core sleeve 11 to form a ventilation channel; one end of the ventilation pipe 12 is connected to the dust suction end piece 13, and the other end is connected to the connector 14; The dust end piece 13 has a front panel 131, the front panel 131 is provided with a first ventilation hole, a support plate 16 is provided between the connecting piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com