A separate thickening belt filter press and sludge dewatering process

A belt filter press, extrusion dehydration technology, used in dehydration/drying/concentrated sludge treatment, water/sludge/sewage treatment, sludge treatment, etc. The problems of large dosage and waste can achieve good dehydration effect, intensify gravity separation, and increase dehydration rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

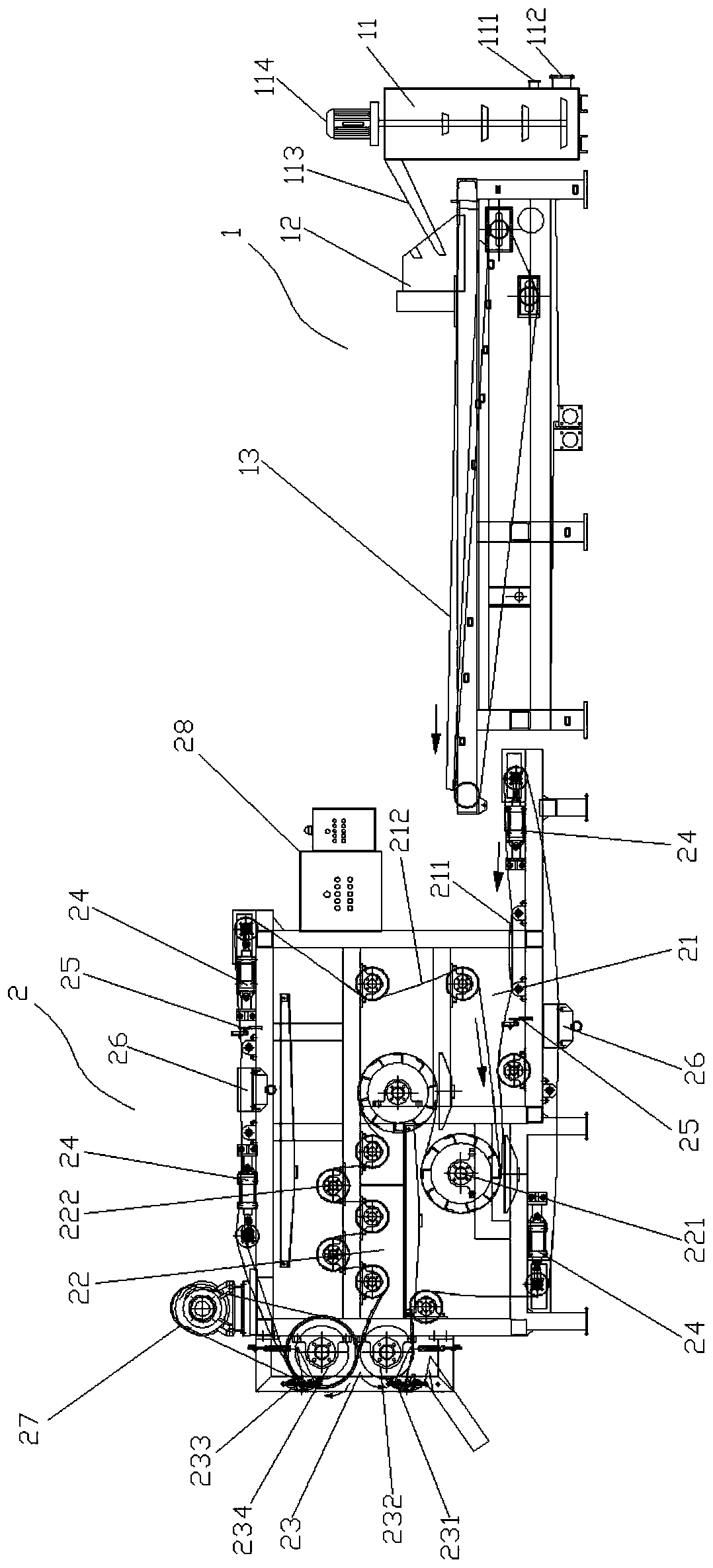

[0031] Such as figure 1 Shown is a schematic structural view of a split concentration belt filter press in a specific embodiment of the present invention. The split concentration belt filter press includes a feed dehydration device 1 and a squeeze dehydration device 2 that are not connected, and one end of the feed dehydration device 1 near the squeeze dehydration device 2 is arranged on the squeeze dehydration device 2 above, which is convenient for the flexible arrangement of equipment.

[0032] The feed dehydration device 1 includes a dynamic mixer 11, a distribution hopper 12 and a slope-type gravity dewatering mesh belt 13, the distribution hopper 12 is located at one end of the slope-type gravity dewatering mesh belt 13 near the dynamic mixer 11, and the dynamic mixer 11 includes a bottom Feeding ports 111 , 112 , top overflow pipe 113 and spiral stirring device 114 , and the outlet of top overflow pipe 113 communicates with distribution hopper 12 . In this embodiment,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com