Hamburger machine

A hamburger machine and heating plate technology, which is applied in kitchen utensils, household utensils, roasters/barbecue grills, etc., can solve problems such as low safety, difficult to clean stains, and insufficient temperature, so as to ensure the safety and convenience of man-machines cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

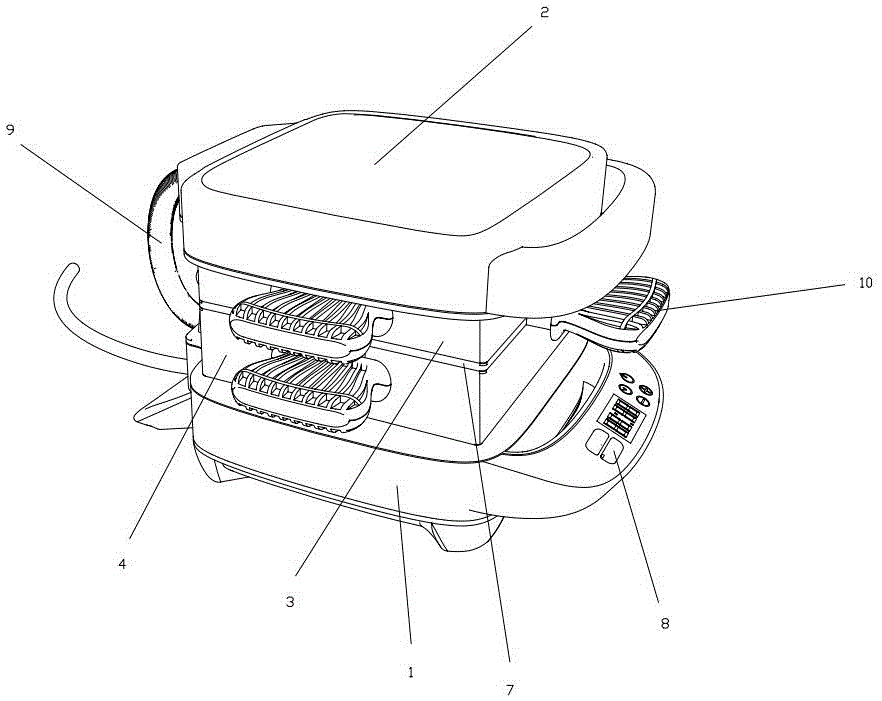

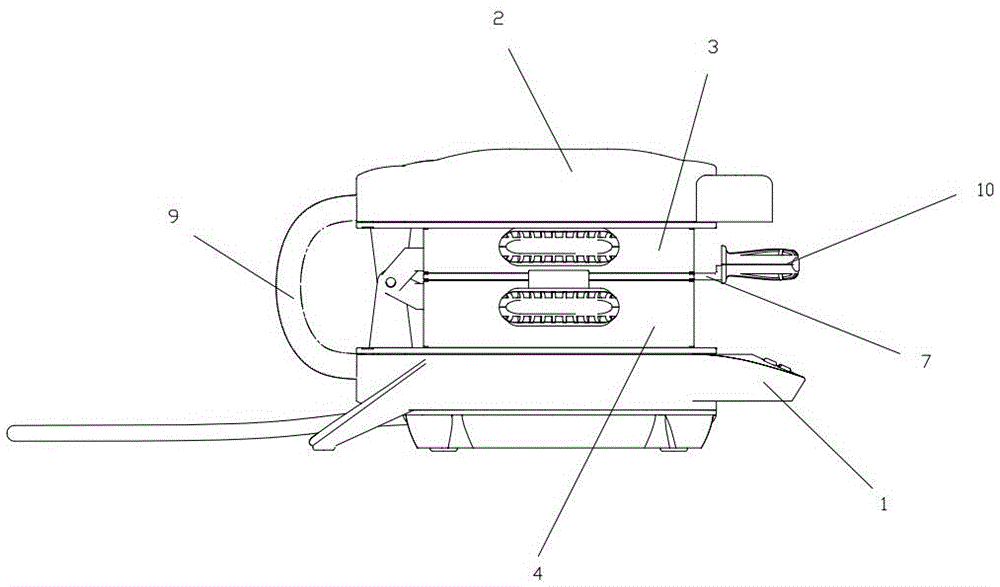

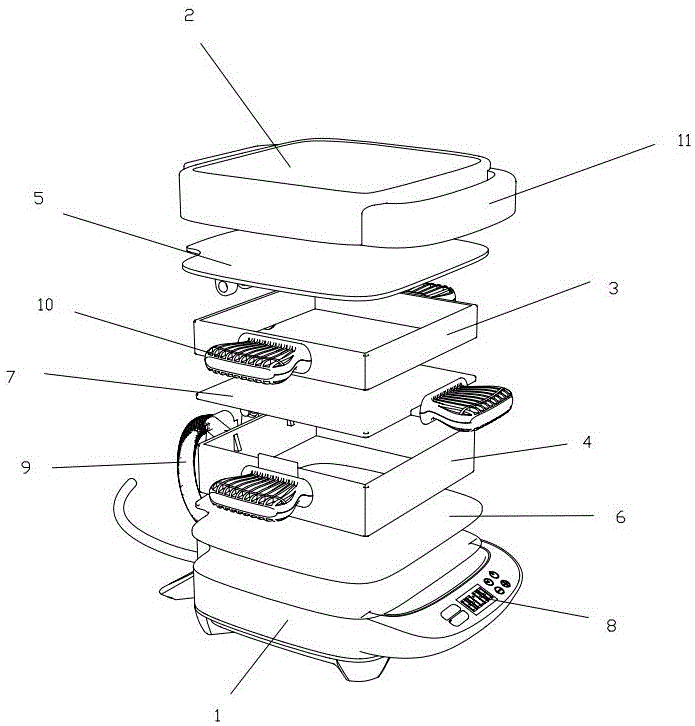

[0015] A kind of hamburger machine described in this embodiment 1, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a heating base 1, a top cover 2 that is hingedly installed with the heating base and can be turned up and down, an upper heating plate 3 and a lower heating plate 4 that are sequentially located between the top cover and the heating base, and the bottom of the top cover is provided with a cover The upper heating plate 5 that lives on the top opening of the upper heating plate, the top of the heating base is provided with the lower heating plate 6 that is close to the bottom of the lower heating plate, and the upper heating plate and the lower heating plate are provided with a cover that is close to the bottom of the upper heating plate. The detachable heat-conducting interlayer plate 7 at the top of the lower heating plate is also provided with a control panel 8 inclined downwards on the heating base.

[0016] A gap is left between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com