Electric power circuit stringing device across river

A technology for power lines and rivers, applied in the direction of overhead lines/cable equipment, etc., can solve problems such as damage from crossing the bridge, stagnation of power lines, affecting the construction process, etc., to ensure stability, ease of erection, and ease of transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

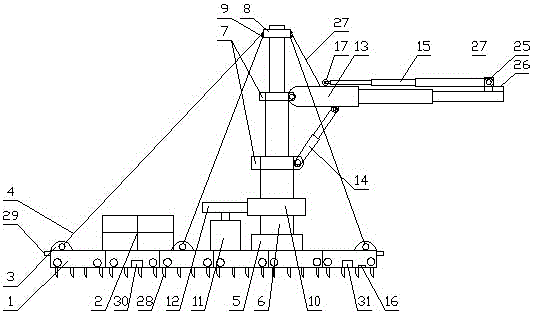

[0029] like figure 1 and figure 2 As shown, a power line stringing device across a river includes a ground anchor mechanism for enhancing stability, a support mechanism arranged on the ground anchor mechanism, and a spanning mechanism arranged on the support mechanism. The anchor mechanism, the support mechanism and the span mechanism are all connected to the control mechanism 16 .

[0030] The ground anchor mechanism includes a ground anchor plate 1 composed of a plurality of ground anchor units, a counterweight unit 2 arranged on the ground anchor plate 1, a load-bearing ring 3 arranged on the side of the ground anchor plate 1, and a load-bearing ring connected with the ground anchor plate 1. 3 connected pull ropes 4 .

[0031] The support mechanism includes a rotary base 5 that is rotated on the ground anchor plate 1, a telescopic rod 6 that is mounted on the rotary base 5, and a fixed seat 7 that is mounted on the telescopic rod 6. The telescopic rod 6 The upper end is...

Embodiment 2

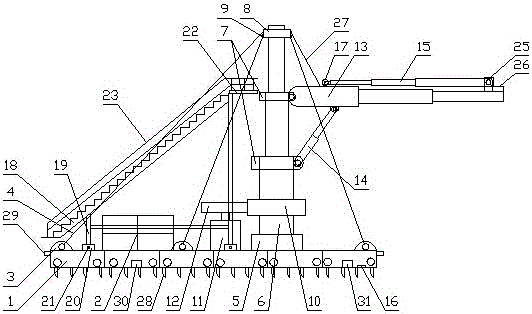

[0043] like image 3 As shown, the difference between it and the second embodiment is that a temporary freight elevator 18 is provided on the ground anchor mechanism, and a chute 20 is provided on the ground anchor plate 1 corresponding to the positions of the four legs 19 of the temporary freight elevator 18. The side of the chute 20 is provided with locking pins 21 for locking the four legs 19 of the temporary freight elevator 18, the temporary operating platform 22 is arranged on the top of the temporary freight elevator 18, and the two side edges of the temporary freight elevator 18 and the Safety fences 23 are all set around the temporary operating platform 22.

[0044] In this embodiment, in order for the construction personnel to easily climb the telescopic rod and the main telescopic arm for operation and maintenance, a temporary freight elevator is set on the ground anchor mechanism, and a temporary operating platform is set on the upper part of the temporary freight ...

Embodiment 3

[0046] like Figure 4 and Figure 5 As shown, the difference between it and Embodiment 2 is that an automatic wire feeding mechanism 24 is provided at the lower part of the main telescopic arm 13, and the automatic wire feeding mechanism 24 includes a bracket 241 arranged at the lower part of the main telescopic arm 13, which is rotatably arranged on The driving wheel set 242 at the inner lower part of the bracket 241, the driven wheel set 243 arranged on the upper inner side of the bracket 241 and matched with the driving wheel set 242, and the output motor arranged at the upper left side of the bracket 241 244, the output motor 244 is electrically connected to the control mechanism 16, the output end of the output motor 244 is connected to the rotating shaft of the driving wheel set 242, and the driving wheel set 242 is connected to the driven wheel set 243 to form a gap for transmitting electric power lines.

[0047] In this embodiment, an automatic wire transmission mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com