Can filling machine

A canning machine and rack technology, applied in the field of canning machines, can solve the problems that the canning volume cannot be accurately controlled, increase the labor cost of production enterprises, and affect the economic benefits of enterprises, so as to improve product quality and enterprise benefits , Reduce labor cost input, avoid waste of canned raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

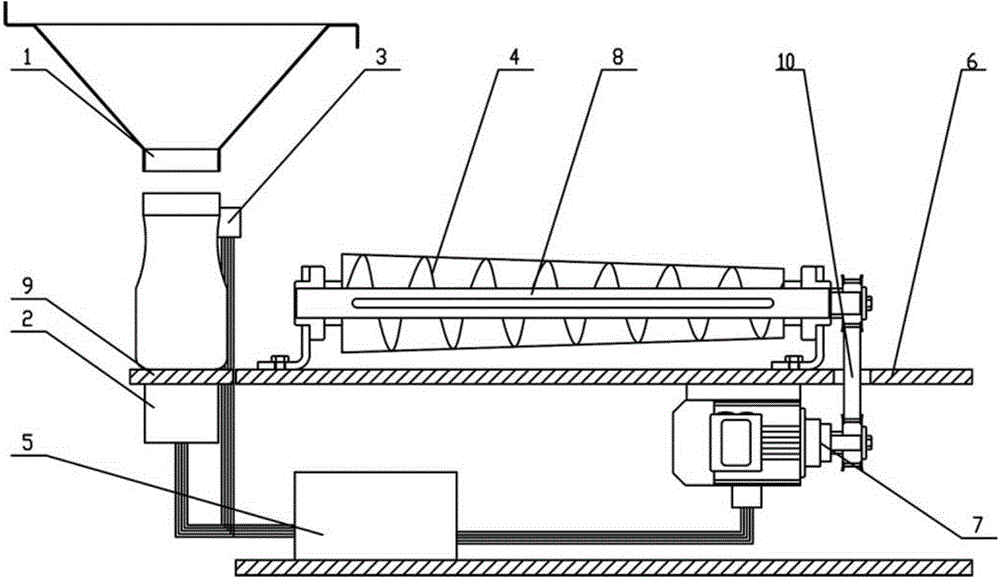

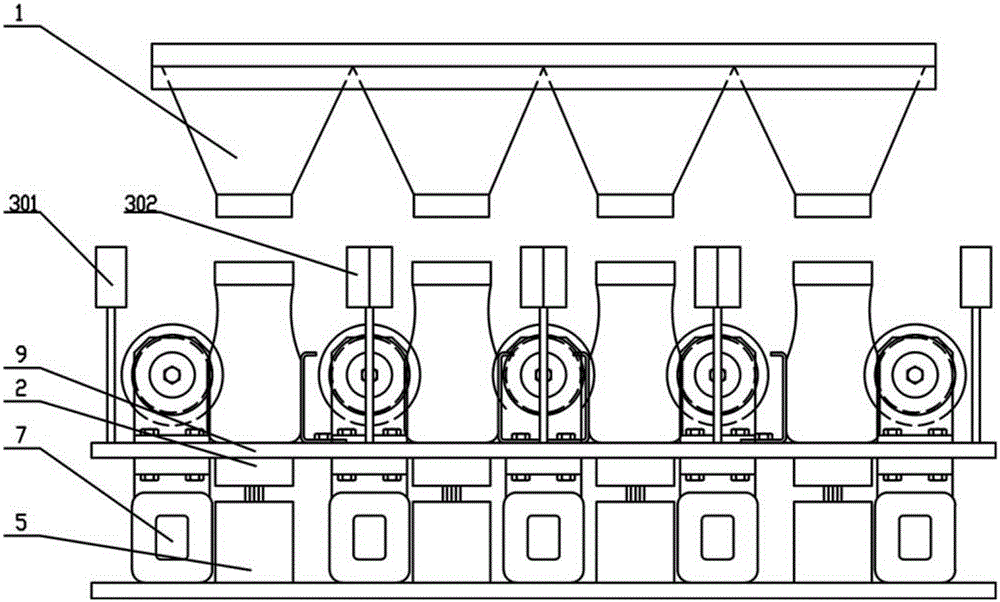

[0020] The device is installed between the empty bottle transportation line and the fruit material conveying network. After the fruit material is selected by the preliminary treatment, it will fall into the empty bottle above the weighing sensor device through the lower hopper. When the weighing sensor device senses that the weight reaches the preset After the standard value is set, the signal is transmitted to the control box. At this time, the control box controls the lower hopper to stop feeding, the power unit and the empty bottle conveyor belt start, and the empty bottle conveyor belt and the full can conveying device transport the weighed bottles to the next a process. The empty bottle conveyor belt continues to drive the empty bottle to move down the hopper. When the empty bottle reaches the empty bottle position sensing device, the empty bottle blocks the infrared emitting device. The infrared receiving device cannot receive the infrared rays emitted by the emitting dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com