High-strength wrinkle-resistant environment-friendly hot-melt plate for decoration and preparation method thereof

A hot-melt plate, high-strength technology, applied in chemical instruments and methods, lamination devices, lamination, etc., can solve the problems of formaldehyde pollution, etc., to achieve the effect of solving pollution, not easy to mold, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

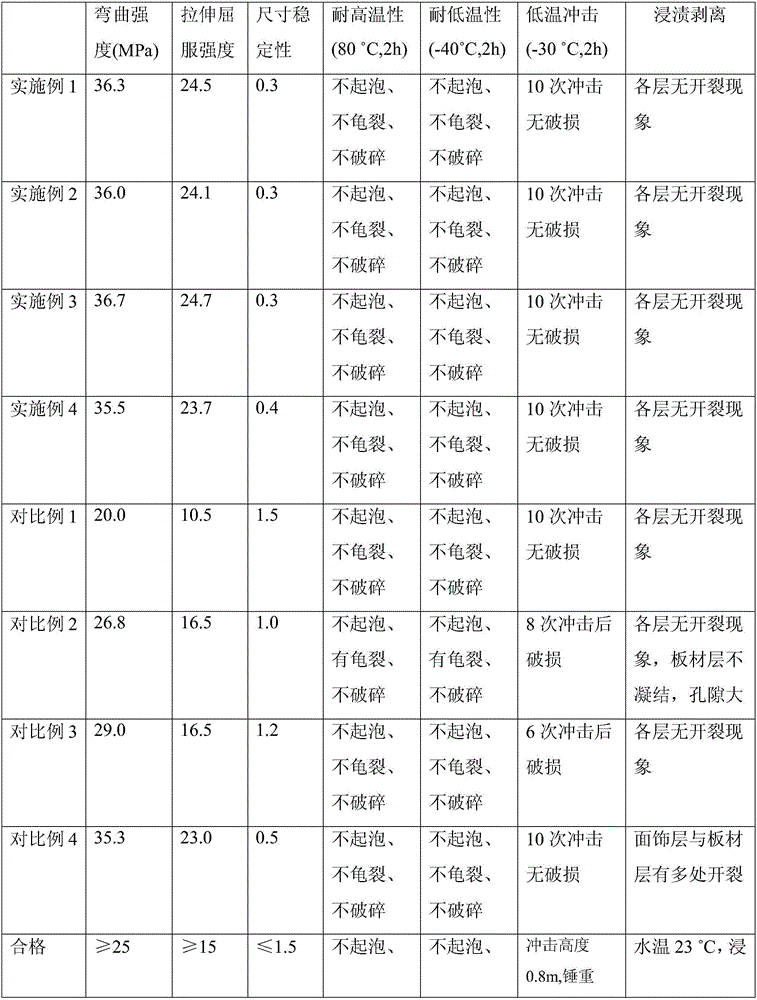

Examples

Embodiment

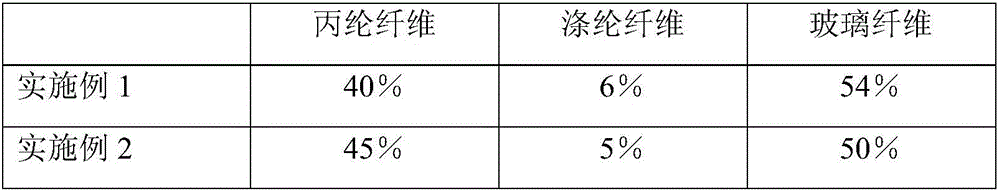

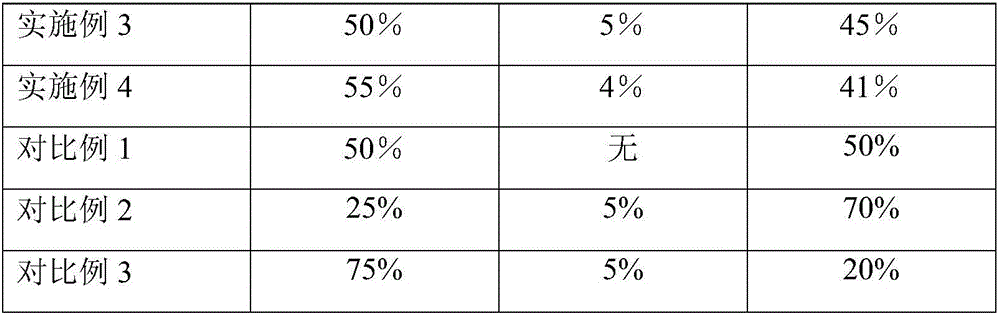

[0045] Raw materials used:

[0046] Polypropylene fiber, Shanghai Petrochemical Y1600, Yangzi Petrochemical S700, Yanshan Petrochemical S1003, etc.

[0047] The polyester fiber is polyester staple fiber with a thickness of 6d and a length of 51mm from Suzhou Yinghu Chemical Fiber Factory, and polyester staple fiber with a thickness of 2.5d and a length of 64mm from Jiangmen Diguan Chemical Fiber Co., Ltd.

[0048]Glass fiber, medium-alkali glass fiber roving (thermoplastic type) CR17-2400, CR21-2400, CR27-2400 from Wuhu Baiyun Fiberglass Co., Ltd., medium-alkali glass fiber yarn RH2400TEX from Anhui Ronghua Fiberglass Co., Ltd., etc.

[0049] As the surface layer, use commercially available chemical fiber cloth or chemical fiber wall covering.

[0050] PE film, low-density polyethylene protective film of Wuxi Xinrun Protective Film Co., Ltd. (medium-high viscosity, thickness 0.04-0.20), low-density polyethylene protective film of Wuhan Kaidi Plastic Products Co., Ltd. (medium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com