Combined wrench and socket device structure

A combined structure and wrench technology, which is applied in the direction of wrenches, screwdrivers, manufacturing tools, etc., can solve the problems of elastic fatigue of elastic parts 7, joints on screw parts, inconvenient use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

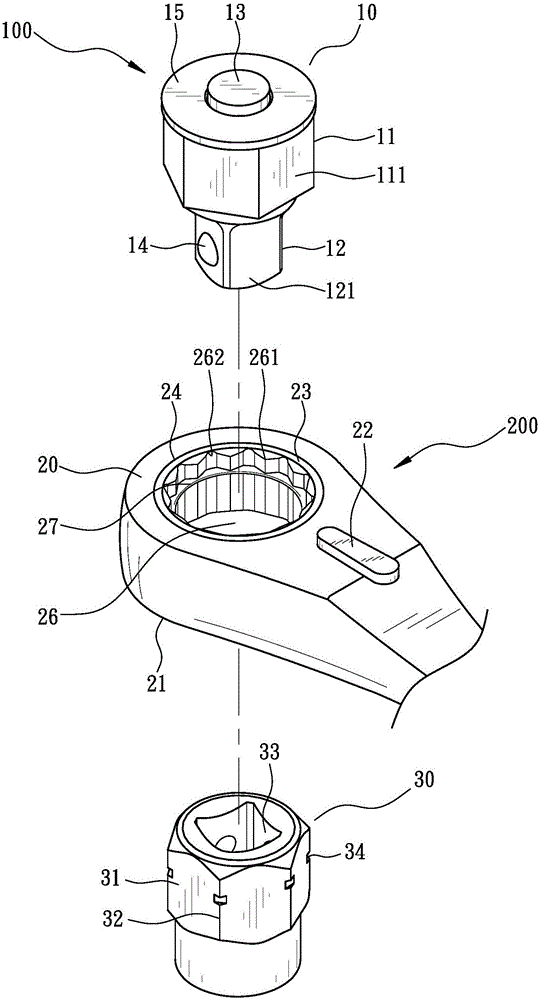

[0066] In order to illustrate the central idea of the present invention expressed in the column of the above-mentioned summary of the invention, it is expressed in specific embodiments. Various objects in the embodiments are drawn according to proportions suitable for illustration and description, rather than according to the proportions and drawings of actual components, and are described first.

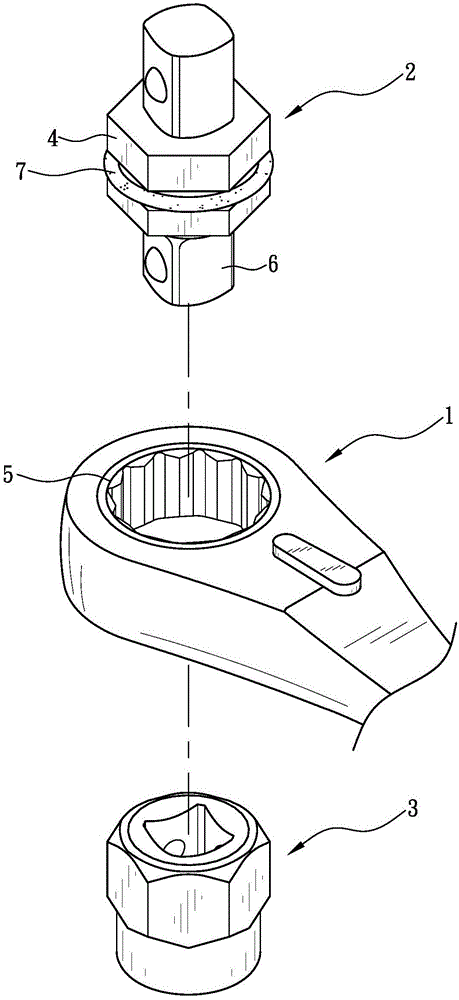

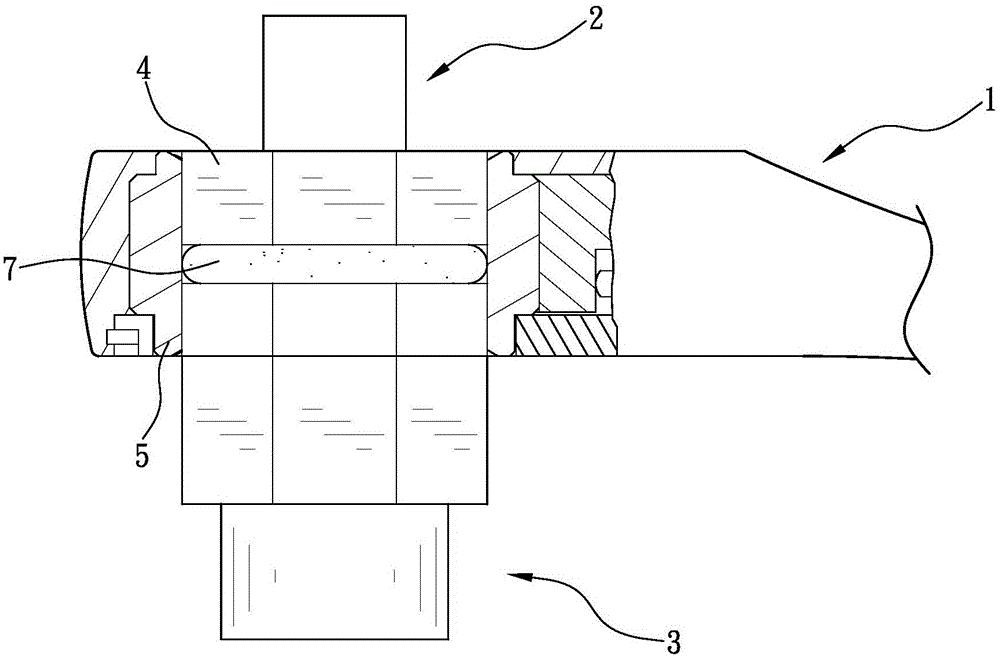

[0067] see Figure 3 to Figure 7 As shown, the combined structure of the wrench and the receiving device of the present invention includes a receiving device 100 and a wrench 200 . The receiving device 100 of the present invention includes a first receiving tool 10 and a second receiving tool 30, the first receiving tool 10 and the second receiving tool 30 can be coupled to each other, and the first receiving tool 10 can be disassembled on the wrench 200 . Wherein, the first receiving tool 10 in the present invention is an adapter, and the second receiving tool 30 is a sleeve. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com