Discharging machine applicable to wheat berry production

A technology of cutting machine and production equipment, applied in the direction of solid separation, filter screen, grille, etc., can solve the problem of falling to other areas of the screen, slow screening efficiency of wheat kernel particles, affecting the work efficiency of the screen, etc. problem, to achieve the effect of convenient and uniform distribution, increase the loading capacity, and improve the distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

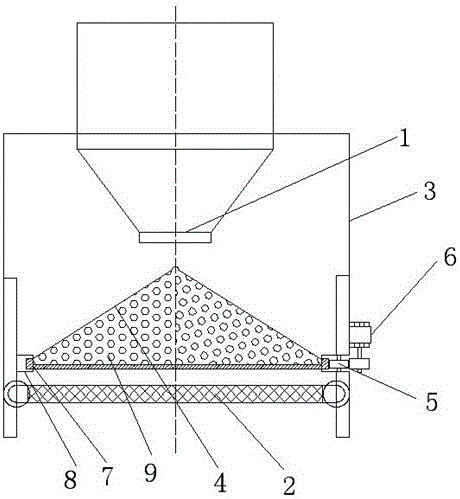

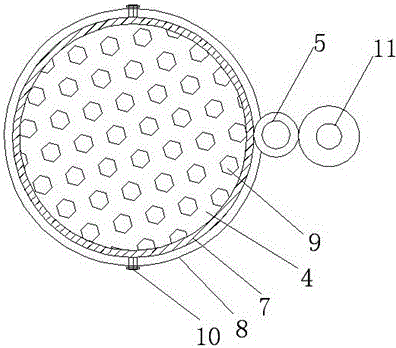

[0015] Embodiment 1: as figure 1 and 2 Shown is a feeder suitable for wheat kernel production, the feeder is installed between the feed port 1 and the screen 2 of the wheat kernel production equipment, and the feeder includes a retaining shell 3. The distribution sieve plate 4, the transmission wheel 5 and the transmission motor 6, the material retaining shell 3 is set between the discharge port 1 and the screen material net 2, and the distribution sieve plate 4 is a conical cloth material protruding upward The sieve plate, the cloth sieve plate 4 is evenly distributed with a plurality of wheat kernel through holes 9, the outer side of the bottom of the cloth sieve plate 4 is provided with a transmission layer 7, and the inner side of the material retaining shell 3 is provided with a ring and transmission layer 7 matching fixed ring rail 8, the cloth sieve plate 4 is movably installed in the fixed ring rail 8 through the transmission layer 7, and the transmission wheel 5 is i...

Embodiment 2

[0016] Embodiment 2: as figure 1 and 2 As shown, the diameter of the wheat kernel through-hole 9 is 4-8 mm, and the distance between two adjacent wheat kernel through-holes 9 is the same as the diameter of the wheat kernel through-hole 9; The wheat kernel through hole 9 on the sieve plate 4 distributes the wheat kernel particles downward. Since the particle size of the wheat kernel itself is 2 to 3 mm, in order to ensure the normal feeding speed and avoid the accumulation of wheat kernel particles, the diameter of the wheat kernel through hole 9 It must be relatively large while ensuring its distribution effect, and the aperture of the wheat kernel through hole 9 should not be too large.

Embodiment 3

[0017] Embodiment 3: as figure 1 and 2 As shown, the transmission layer 7 and the transmission wheel 5 are driven by gears or friction, and the transmission layer 7 is a gear transmission ring or a friction transmission ring; the cloth sieve plate 4 mainly rotates through the close contact between the transmission wheel 5 and the transmission layer 7 , to avoid the accumulation of wheat kernel particles, and at the same time, through the dual action of centrifugal force and gravity, the uniform distribution of wheat kernel particles is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com