Wire connection device

A technology of wire connection and screw connection, which is applied to the parts, connections, coupling devices and other directions of the connection device, which can solve the problems of affecting the safe operation of the equipment, prone to heat generation, and easy to swing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

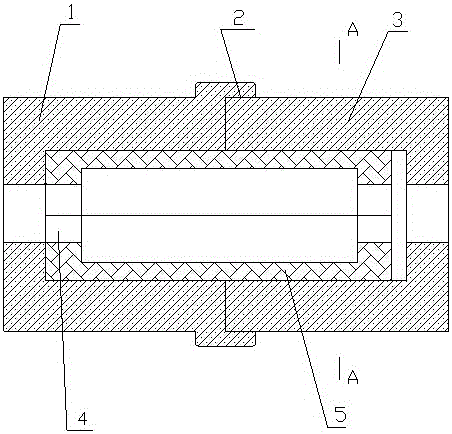

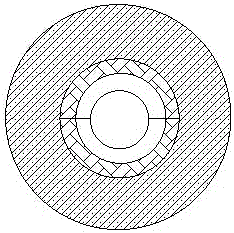

[0011] It can be seen from the drawings that the wire connection device is characterized in that: the wire connection device is composed of an outer sleeve I1, an outer sleeve II3, and an inner sleeve made of insulating materials 4, and the outer sleeve I1, the outer sleeve The sleeve II3 is threadedly connected with the inner sleeve 5 . The inner sleeve 5 is composed of two symmetrical rings, and a stepped through hole 4 is provided in the inner sleeve 5, and the diameter of the through holes at both ends is smaller than the diameter of the through hole in the middle. A cylindrical concave hole 2 is provided at the junction of the end faces of the outer sleeve I1 and the outer sleeve II3, and the outer diameter of the outer sleeve II3 is placed therein.

[0012] Of course, the above description is not a limitation of the present invention, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com