Backlight module

A technology for a backlight module and a backplane, which is applied in the field of optical modules, can solve the problems of increasing the manufacturing cost and assembly process of the backlight module, and the bending deformation of the optical film, thereby achieving the effect of saving the manufacturing cost and the assembly process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of a preferred embodiment with reference to the drawings. The directional terms mentioned in the following embodiments, such as: up, down, left, right, front or back, etc., are only referring to the directions of the drawings. Accordingly, the directional terms are used to illustrate and not to limit the invention.

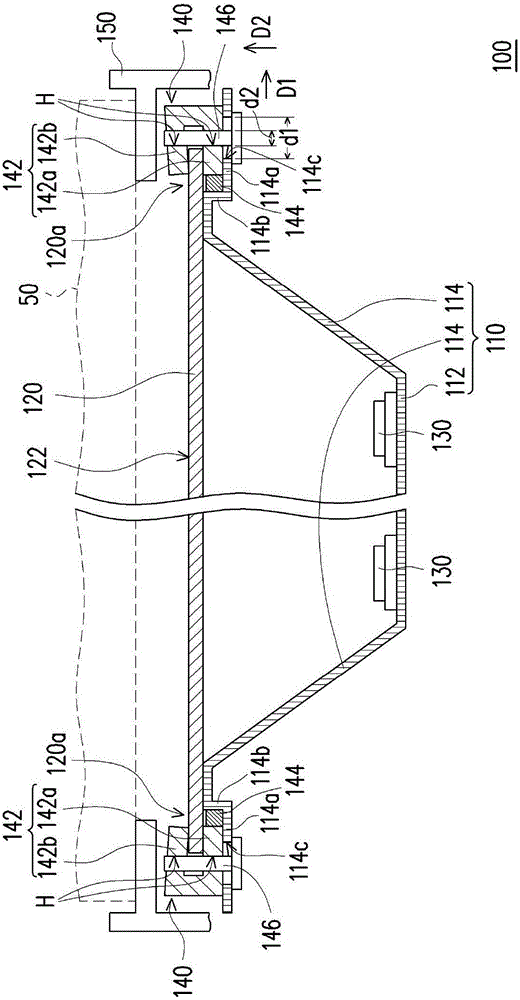

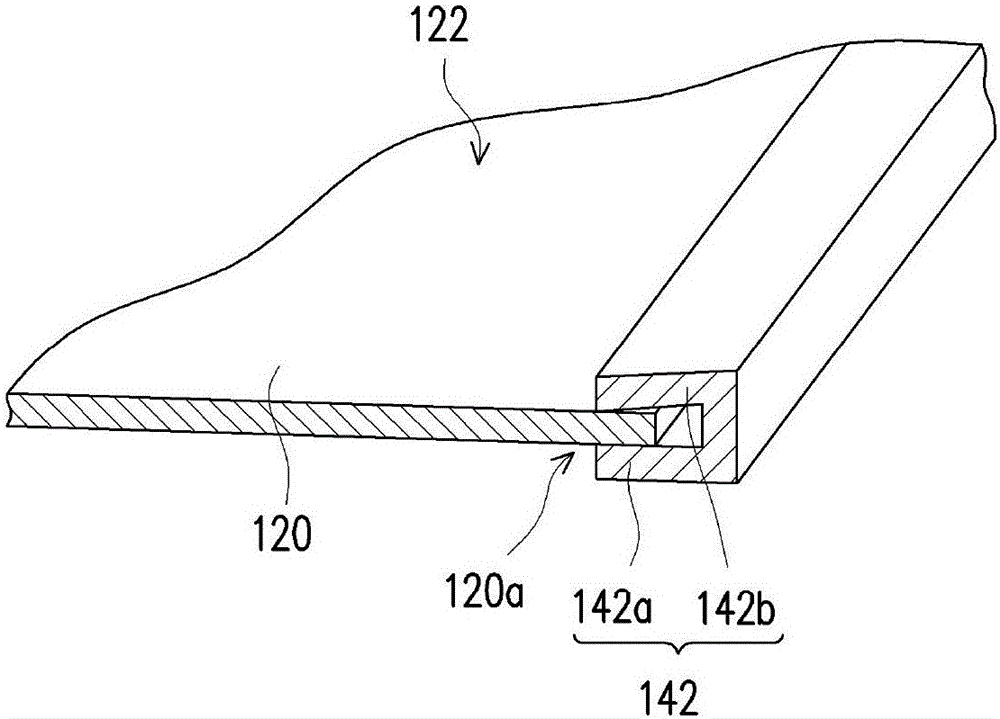

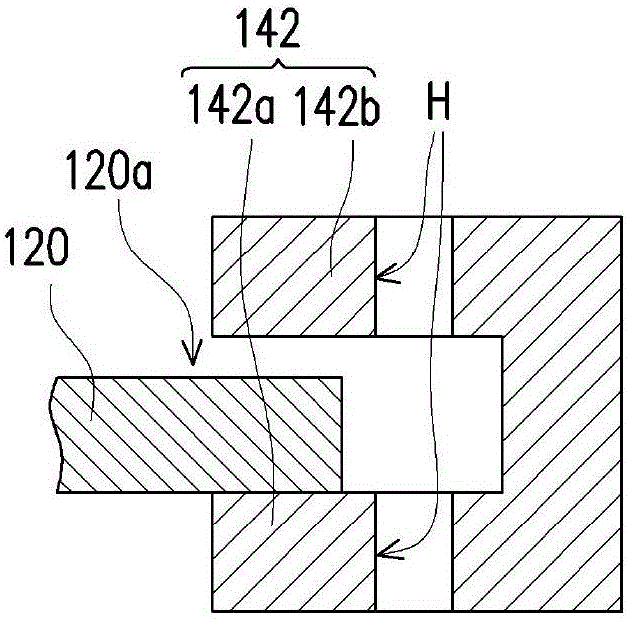

[0025] figure 1 is a schematic diagram of a backlight module according to an embodiment of the present invention. figure 2 yes figure 1 Partial perspective view of the clamping structure and the optical film. Please refer to figure 1 and figure 2 , the backlight module 100 of this embodiment includes a backplane 110 , an optical film 120 , a plurality of light sources 130 and two clamping components 140 . The backboard 110 includes a bottom board 112 and a plurality of side boards 114 connecte...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap