Method and equipment for making pickled peppers

A kind of equipment and technology for pickling peppers, which is applied in the field of pickled peppers production method and its equipment, can solve the problems of insufficient mixing of peppers and salt, inconsistent fermentation degree and taste of peppers, uneven mixing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

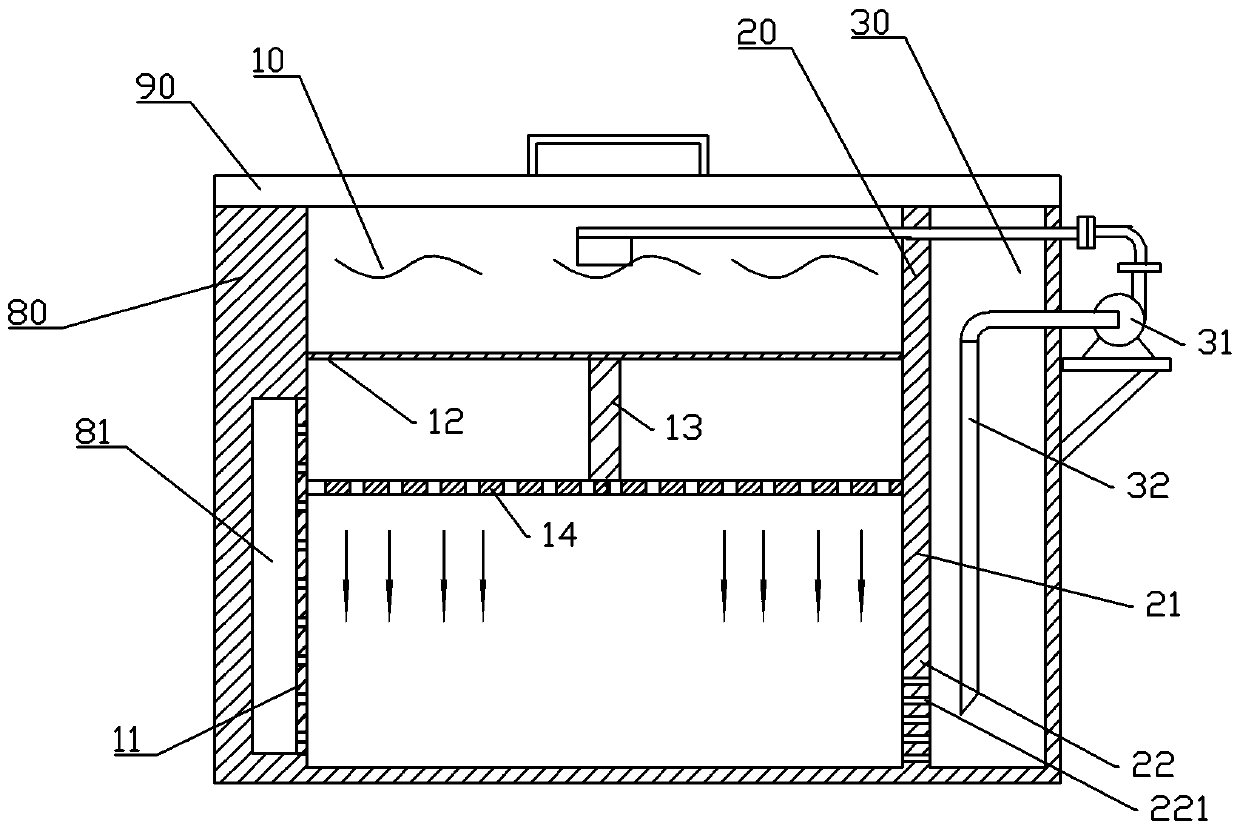

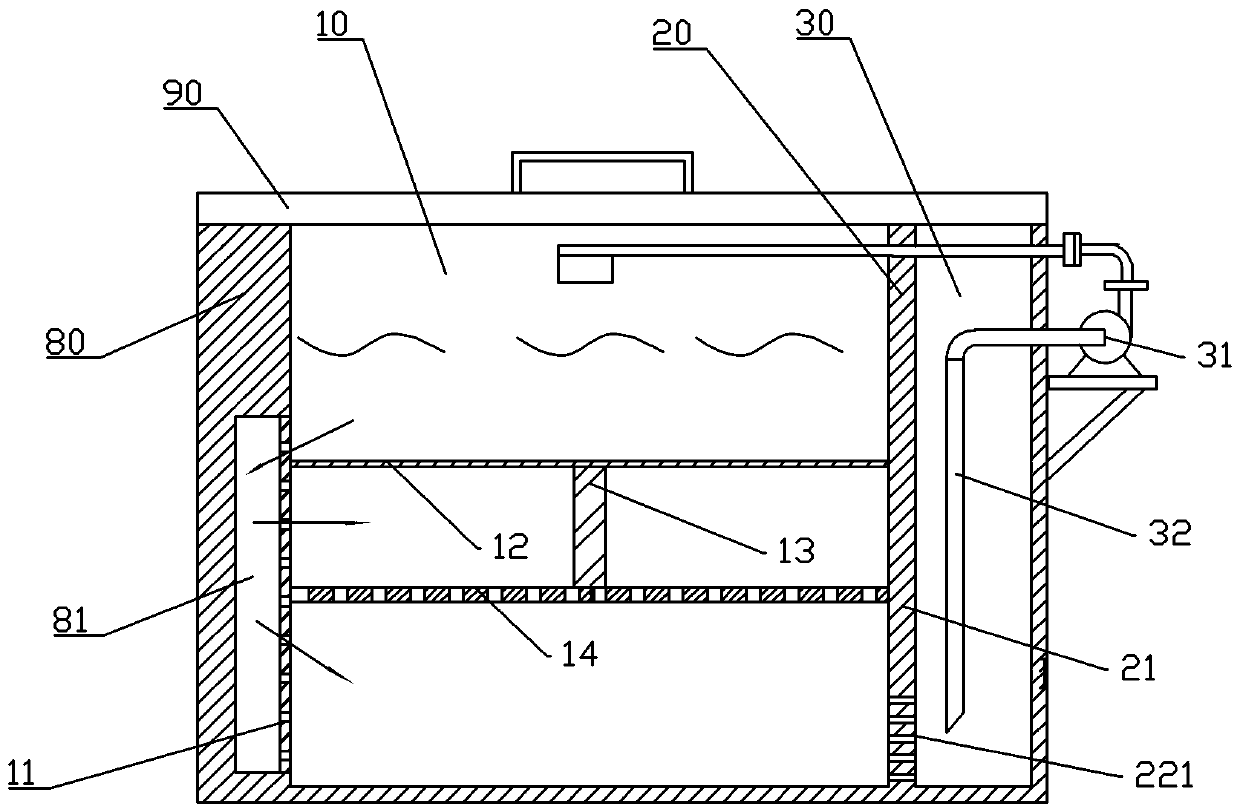

[0021] Example 1 as figure 1 A kind of pickled pepper production equipment shown includes a pickling pool 80 and a sealing cover 90 that can close the pickling pool. There is a partition 20 across the pickling pool, and the partition 20 separates the pickling pool 80 into pickling pools on the left. Control zone 10 and right circulation zone 30, the upper part of the partition 20 is a solid partition part 21, the bottom of the partition 20 is a filter part 22, and a group of permeation holes 221 are opened in the filter part 22; a circulation device is installed in the circulation zone 30 With the pipeline 32, the circulation device is an anti-corrosion pump 31, and the anti-corrosion pump 31 pumps salt water from the bottom of the circulation area through the pipeline 32, and then injects it into the pickling area 10 through the outlet pipe; there are valves fixed together in the pickling area 10 Plate 12, connecting column 13 and floating plate 14, also have the filter plate...

Embodiment 2

[0023] Embodiment 2: The difference between embodiment 2 and embodiment 1 is that the helical stirring blade is pivotally connected under the floating plate. The pool wall of the pickling pool is equipped with a limited step below the floating plate.

[0024] When in use, when the floating plate is pushed down by the valve plate, the spiral stirring blade will rotate by itself, so that the peppers around the spiral stirring blade will rotate horizontally, so that the salt water and peppers can be mixed more fully. In the process of pressing down the floating plate, the limit step can limit the floating plate to prevent it from over-extruding the peppers.

Embodiment 3

[0025] Embodiment 3: a kind of method for making pickled peppers, wherein: step 1, according to one layer of capsicum, one layer of salt is laid in the pickling pond, step 2, uses the strainer to cover the top of capsicum, then injects water in the pickling pond, until Water floods the filter screen by 10-20cm; step 3, slide the fixed valve plate, connecting column and floating plate into the pickling area, and the floating plate is located above the valve plate; step 4, use the sealing cover to cover the pickling pool Tighten, keep the pickling tank in a sealed state; step 5, open the circulation device after sealing it for a week, so that the water circulates in the circulation area and the pickling area, and the time for the circulation device to be opened is 0.5 to 1 hour; step 6, seal it for two weeks and then again Turn on the circulation device, and the second opening time of the circulation device is 0.5 to 1 hour; step 7, seal at 25-35°C for 25 days, then it can be fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com