Switched reluctance motor starting methods

An electric motor, reluctance motor technology, applied in the direction of a single reluctance motor starter, motor control, motor generator/starter, etc., can solve the problems of unacceptable, long duration of the first step, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

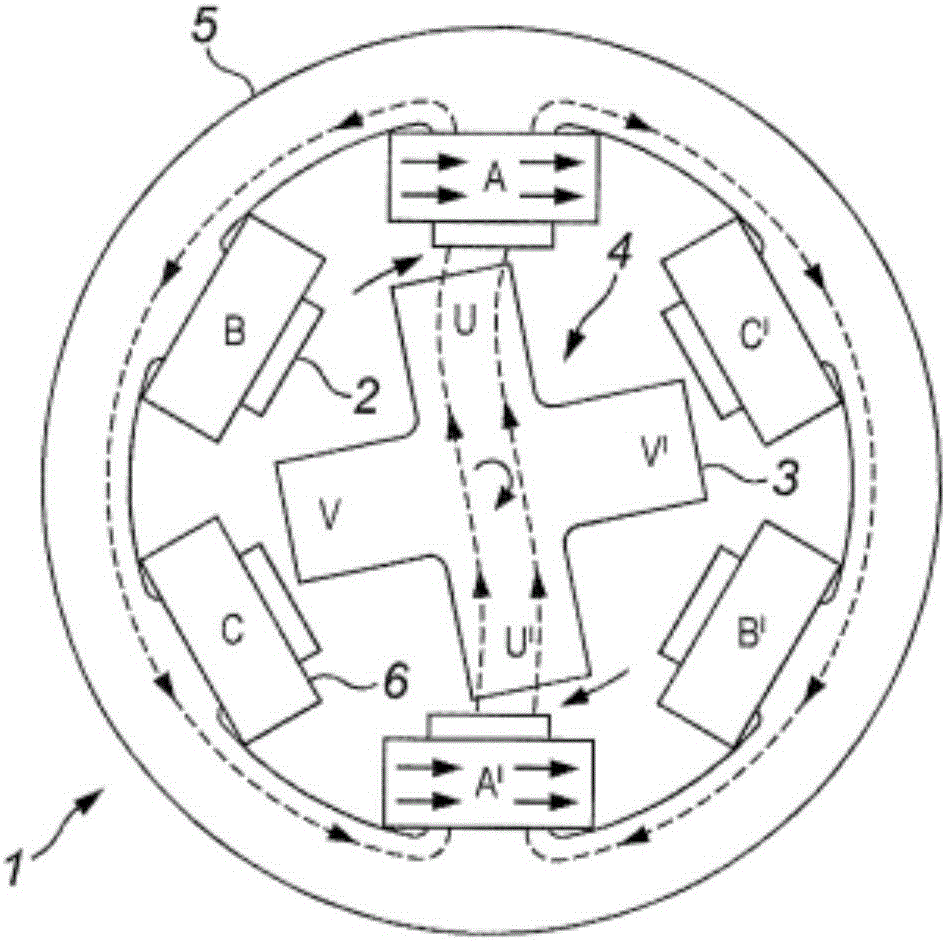

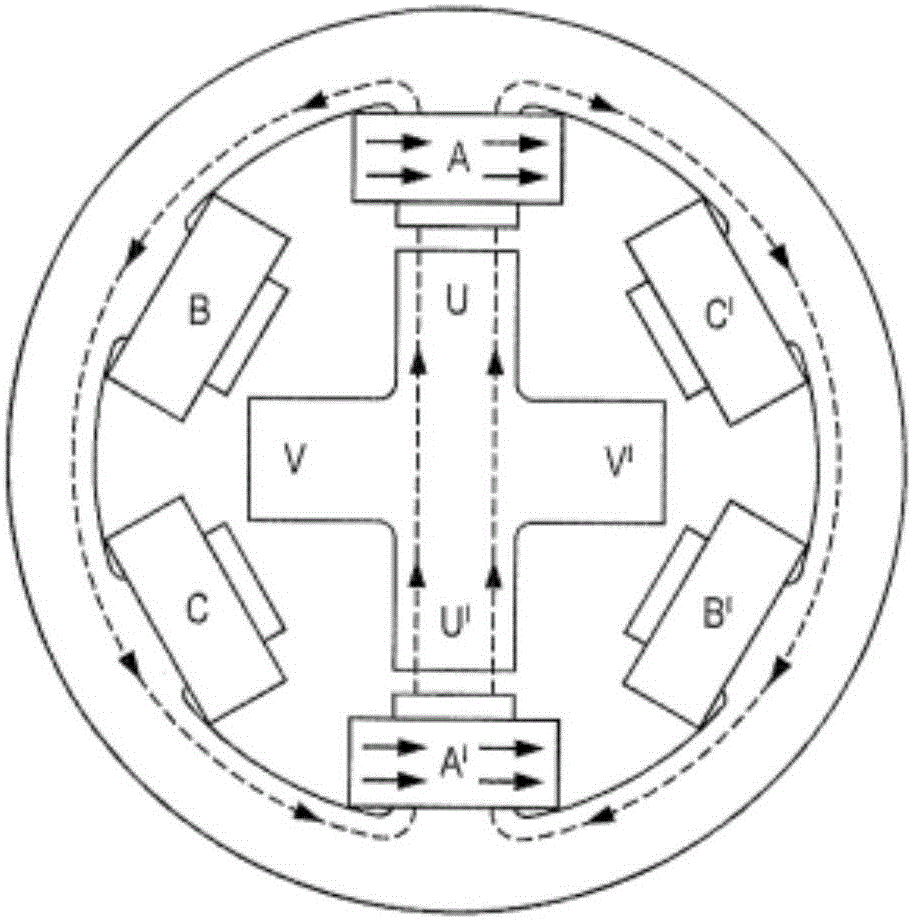

[0077] Figure 12 The flowchart of shows an example method of starting a switched reluctance motor as Figures 9 to 11 As shown, the stages of rotation of the switched reluctance motor are demonstrated. The motor in this example is similar to that of Figures 1 to 8, with six stator poles and four rotor poles (similarly labeled ABCA'B'C' and UVU'V'). (ABCA'B'C' likewise denote poles and individual coils of poles). It operates a motor control circuit similar to Figure 5 motor control circuit, except for the control circuit 10'( Figure 13 ) are arranged to control the switches 21 to 26 to turn on and off the coils of the motor as described in this example. In order to do this, a start-up controller 50 is provided (preferably implemented with additional programming in a microcontroller).

[0078] The rotor starts at any position, where the rotor may be stationary or slowly moving, such as Figure 9 as shown ( Figure 12 In step 101), all coils are turned off. In such a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com