Media transport in rotor shaft

A technology of rotor and hollow shaft, which is applied in the field of medium conveying system in the rotor shaft, which can solve the problems of excessive weight of the rotor shaft, excessive medium volume, and limited low weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

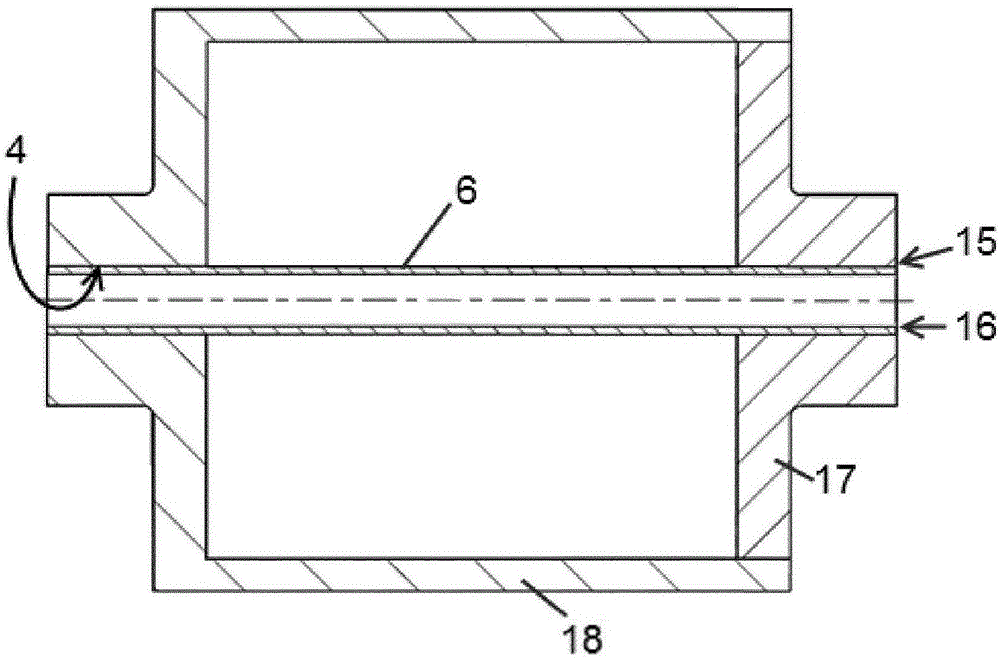

[0024] figure 1A rotationally symmetrical rotor hollow shaft for a rotor of an electric machine is shown. The rotor hollow shaft comprises a cylindrical barrel 2 which is closed on both sides by end flanges 1 made of steel, wherein in each case a journal is positioned on the end flange 1 3. Here, the journal may be formed on the end flange in an inseparable form, or may be a separate part held on the end flange. In this case, coaxial access holes 4 are provided on the two journals, which, as long as they are not closed, provide access to the shaft cavity 5 surrounded by the cylindrical barrel 2 . As a guide element, a hollow cylindrical tube 6 is provided, consisting of a soft material such as aluminium or plastic, the outer diameter of which can be seen being smaller than the inner diameter of the shaft cavity 5 . On the side of the shaft chamber 5 , the tube piece 6 is pressed on both sides into a screwed annular receptacle 7 , which emerges around the inlet opening 4 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com