Nitrogen gas supply equipment for bulk carrier

A technology for supplying equipment and bulk carriers, which is applied to bulk cargo, fire rescue, etc., and can solve problems such as hydrogen explosions, ship accidents, and limited berthing ports, and achieve suppression of construction costs, fewer design changes and modifications, and suppression Effects of Construction Costs and Retrofit Costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

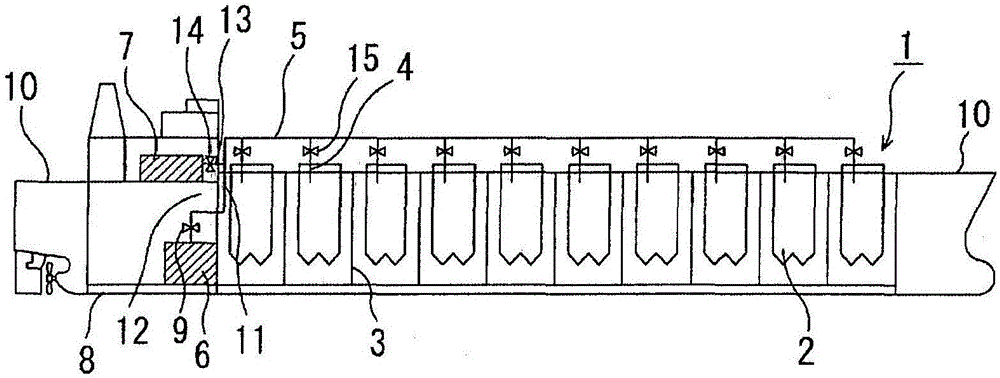

[0037] figure 1 It is a figure which shows the outline|summary of Embodiment 1 of this invention, and the bulk carrier 1 has several cargo holds 2 for loading bulk cargo. These several cargo holds 2 are arrange|positioned side by side with the bulkhead 3 interposed between them in the ship's length direction, and 2 - several cargo holds 2 are arrange|positioned with the bulkhead (not shown) in the ship width direction similarly.

[0038] A gas supply branch pipe 4 is provided on the upper part of each cargo compartment 2, and, although not shown in the figure, there is provided an input piping that can be connected to a loading and unloading piping on the land side, and a load that is discharged from the input piping is provided. input port.

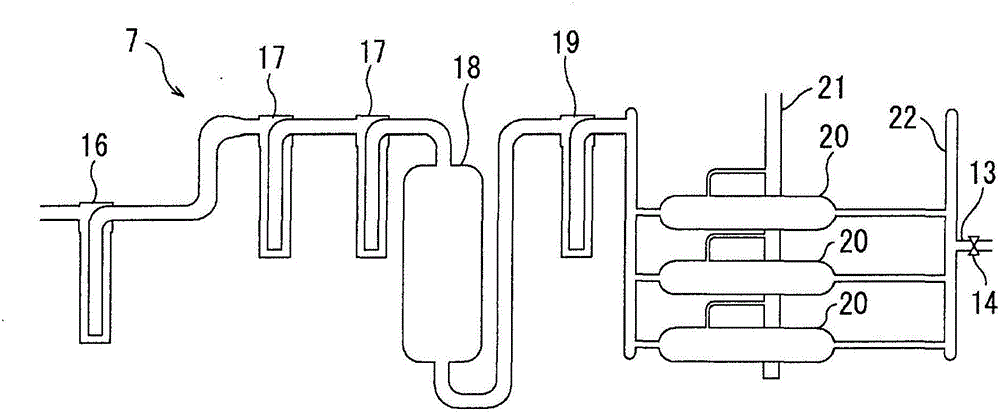

[0039] And each gas supply branch pipe 4 is branched from the gas supply main pipe 5, and the carbon dioxide sent from the carbon dioxide supply equipment 6 or the nitrogen sent from the nitrogen generator 7 can be passed through the ga...

Embodiment 2

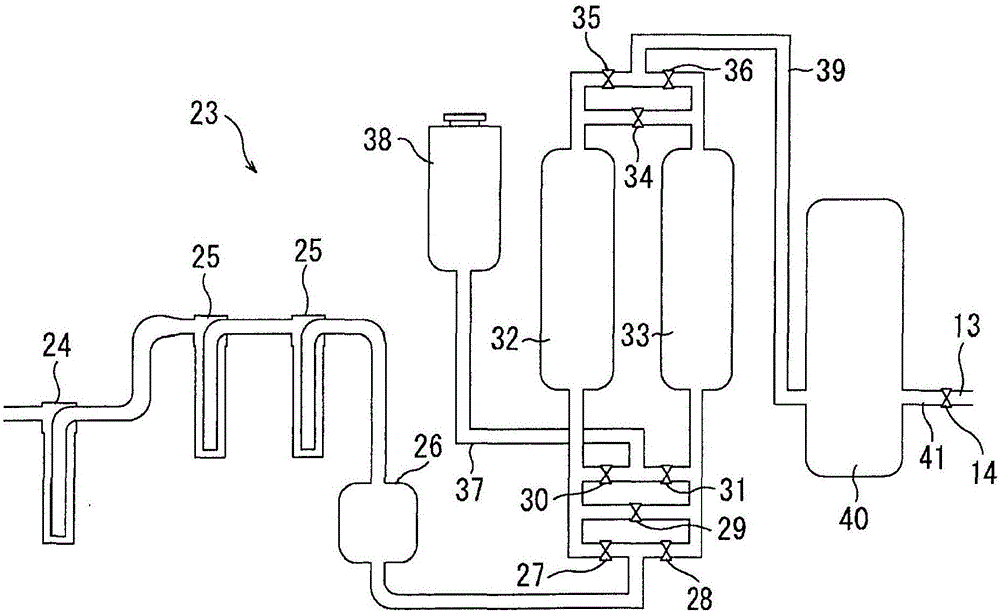

[0056] In Example 2, the nitrogen generator 7 using the so-called membrane separation method, such as the membrane unit 20 in Example 1, is replaced by one that absorbs nitrogen and oxygen in the air in a pressurized state, and utilizes the difference in the adsorption speed of the two. The nitrogen generator 23 of the so-called PSA system for separation is completely the same as that of the first embodiment in other configurations.

[0057] figure 2 It is a schematic diagram showing the structure of the nitrogen generating device 23 of Example 2, including: an air compressor 24, an air filter 25 (two in series), an activated carbon tank 26, a first valve 27, a second valve 28, a first Three valves 29, fourth valve 30, fifth valve 31, first adsorption tower 32, second adsorption tower 33, sixth valve 34, seventh valve 35, eighth valve 36, exhaust outlet pipe 37, muffler 38, The connecting pipe 39 , the product tank 40 , and the nitrogen gas outlet pipe 41 are connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com