Fluked burying devices

A fluke and chain link technology, applied in the field of fluke embedding devices, can solve the problems of cost, handling and operation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

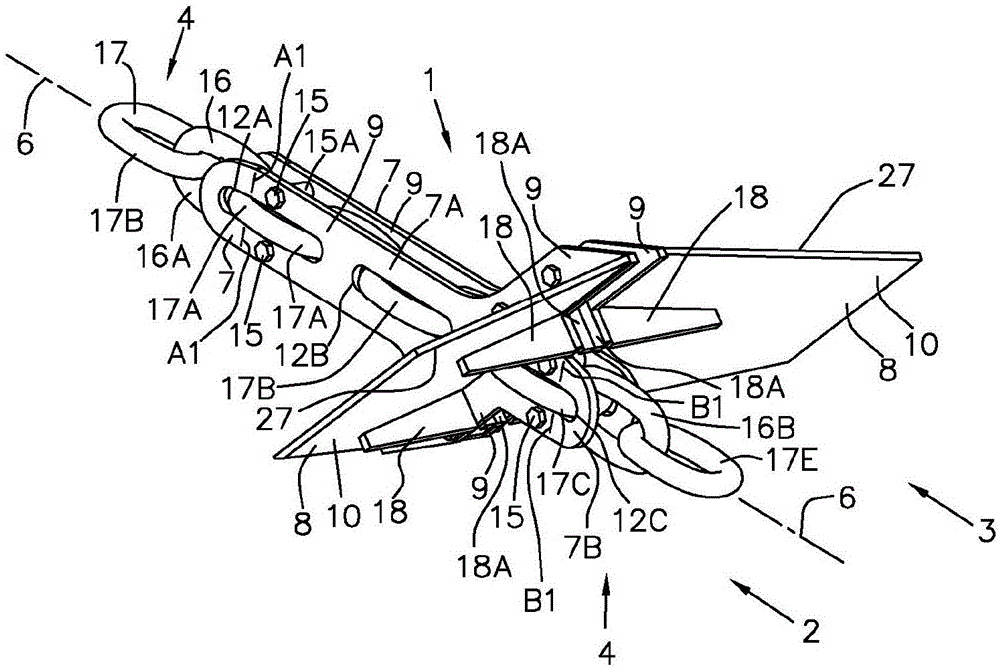

[0043] refer to Figure 1 to Figure 6 , the fluke embedding device 1 is formed by two parts 2, 3, that is, the fluke embedding device 1 comprises a port half 2 and a starboard half 3 arranged to surround the chain cable 4 and They are attached opposite each other in parallel with the chain cables 4 . The fluke embedding device 1 is about the symmetry plane 5 ( Figure 4 and Figure 5 ) symmetrical, the plane of symmetry 5 contains the axis 6 of the chain cable 4 which extends inwardly within its shank 7 . When the anchor fluke embedding device 1 is buried in the seabed 39 ( Figure 8 ) in the seabed soil 38, the plane of symmetry 5 is oriented vertically. The port half 2 and the starboard half 3 comprise a shank 7 and a fluke 8 . The handle 7 includes a front handle 7A extending to the front of the fluke 8 and a rear handle 7B extending to the rear of the fluke 8 . The shank 7 and the fluke 8 are respectively formed by a plate 9 and a plate 10 joined together at a joint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com