Seat belt pretensioner and method for assembling a seat belt pretensioner

A technology of seat belts and tensioners, applied in the field of rotating tensioners and assembling such seat belt tensioners, can solve problems such as impact and achieve the effect of simplification of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

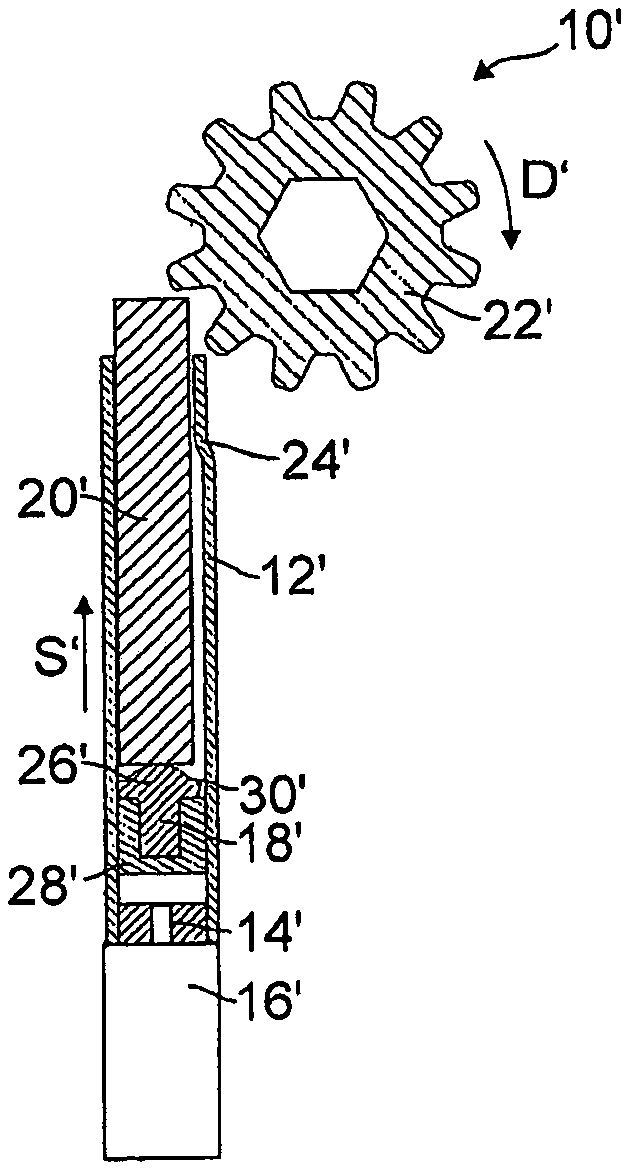

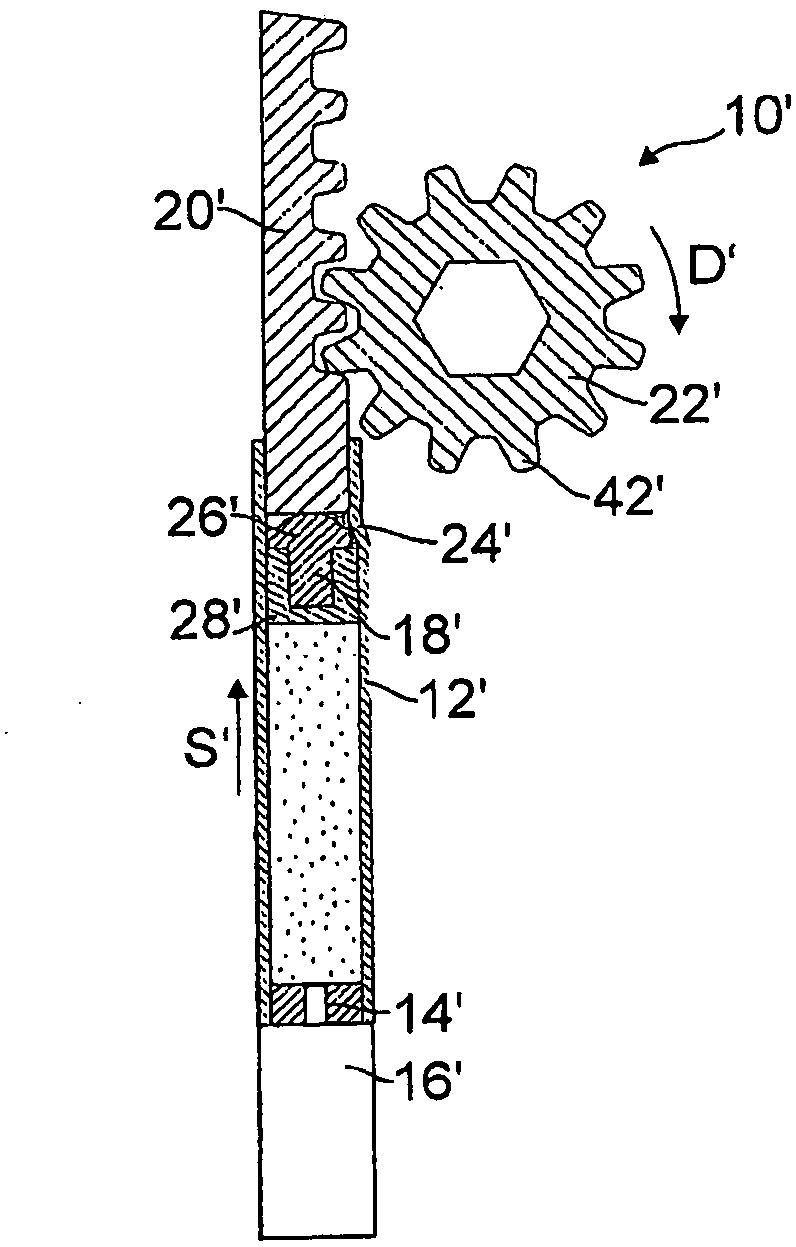

[0024] exist figure 1 and 2 A seatbelt pretensioner 10' for a prior art vehicle is shown in FIG. 2 , comprising an elongated, cylindrical pressure vessel 12' to which a gas generator 16' is connected via a channel 14'. Arranged in the pressure vessel 12' is a piston 18' mounted movably in the tensioning direction S' and a thrust mechanism 20' cooperating with a gear 22', here a push rod, which is in the tensioning direction S' It is arranged in front of the piston 18' and bears against it.

[0025] The longitudinal extension of the thrust mechanism 20' is longer than the distance of two teeth of the gear 22'. The thrust mechanism 20' is made of a relatively soft material so that the teeth of the gear 22' can press into the thrust mechanism 20' as the thrust mechanism moves over the gear 22'.

[0026] On the front end of the pressure vessel 12 ′ in the tensioning direction S′, a stop 24 ′ is provided, which limits the movement of the piston 18 ′ in the tensioning direction S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com