PCB (Printed Circuit Board) lift etching machine and using method thereof

A technology for corrosion machines and lifting motors, which is applied in chemical/electrolytic methods to remove conductive materials, manufacture electrical components, and printed circuits. Speed up PCB board corrosion and other problems, and achieve the effect of easy promotion, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

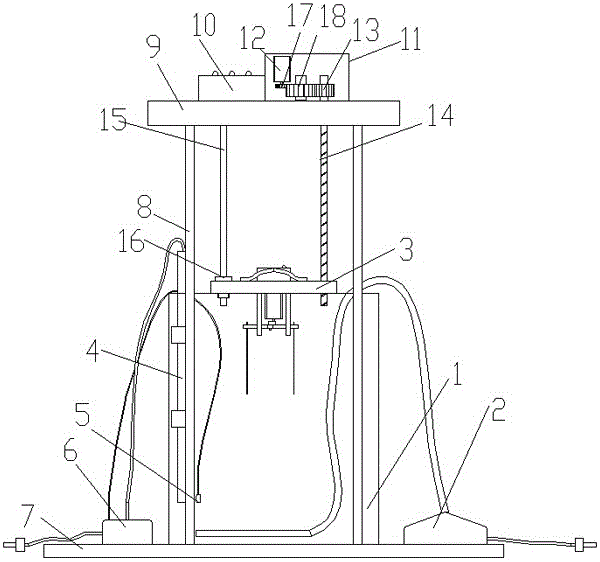

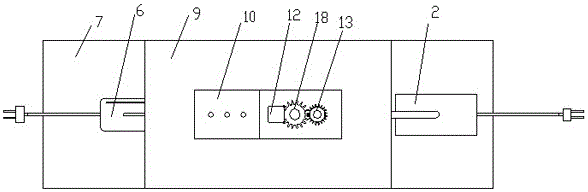

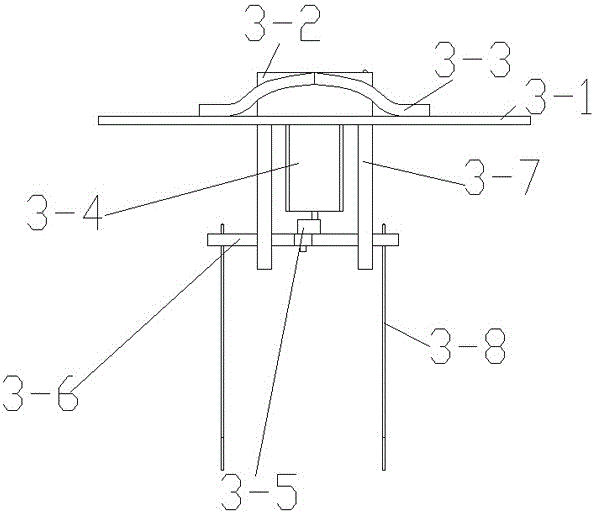

[0025] Such as Figure 1-6 As shown, a pcb board lifting corrosion machine includes a base 7, and the base 7 is provided with a corrosion box 1, a bubble generator 2, and a heating temperature control device, and the heating temperature control device heats the corrosion box 1, and the bubbles The generator 2 communicates with the corrosion box 1 through a gas pipe, and the corrosion box 1 is provided with an upper cover 3-1, and a lifting device for driving the upper cover 3-1 to lift is arranged above the upper cover 3-1, and the upper cover 3-1 -1 is provided with a vibrating device 3, the lifting device includes a top plate 9, a lifting control box 10, a transmission device, the base 7 is provided with a support column 8 supporting the top plate 9, and the transmission device includes a lifting motor 12. Drive gear 17, transmission gear 18, output gear 13, guide rod 15, screw rod 14, the upper end of screw rod 14 is pierced with top plate 9, the lower end is pierced with u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com