Control method for adding water into mixture of sintering machine

A control method and technology for mixing materials, which are applied to controllers with specific characteristics, electric controllers, etc., can solve problems such as the determination of adjustment parameters affecting the automatic control system, the inaccurate setting of water addition, and the difficulty in determining the range of parameters. Achieve the effect of improving the accuracy of feedback correction, solving the lag problem of mixing and adding water, and improving the accuracy and real-time performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

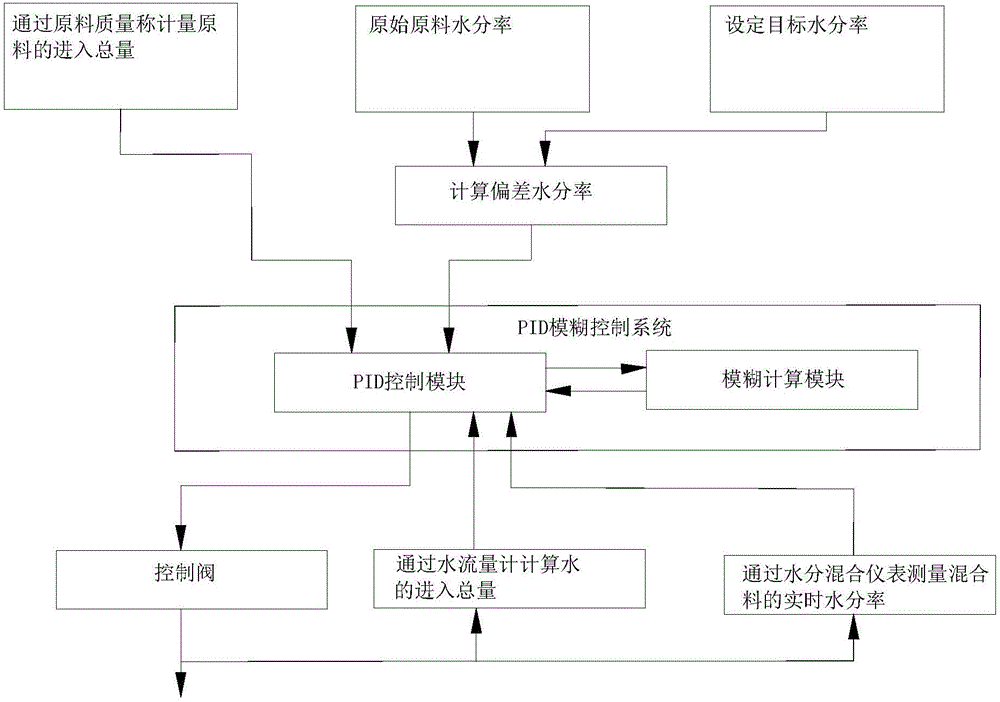

[0031] This embodiment provides a control method for adding water to the sintering machine mixture, including the following steps:

[0032] Step 1. First, set the target moisture content of the mixture according to the purpose of the mixture, and then put the raw materials into the transmission area at multiple feeding points. The transmission area is a conveyor belt for transporting the falling raw materials into the mixing area. The conveyor belt is provided with a raw material moisture meter for measuring the moisture content of the original raw material, the raw material mass scale is installed on the feeding point, and the water flow meter is installed on the control valve of the water inlet system, and the raw material mass scale is used to measure the raw material The total amount of water entering is measured by a water flow meter.

[0033] Step 2. Measure the real-time moisture rate of the mixture through the mixing moisture meters at multiple tracking measurement poi...

Embodiment 2

[0037] Different from Example 1, the real-time original tracking moisture rate of raw materials is calculated by the PID control module according to the real-time moisture content of the measured mixture, the real-time water addition amount and the real-time addition total amount of raw materials, and obtained after fuzzy processing Raw material tracking moisture rate correction value KD, the calculation of the raw material tracking moisture rate correction value KD firstly calculates corresponding The original tracking moisture ratio MI1 of multiple raw materials, the calculation formula of the original tracking moisture ratio MI1 of the raw materials is:

[0038] A plurality of raw material original tracking moisture ratios MI1 and raw material original moisture ratios MI0 pass through the fuzzy calculation module to obtain the corrected output value of the raw material tracking moisture ratio correction value KD.

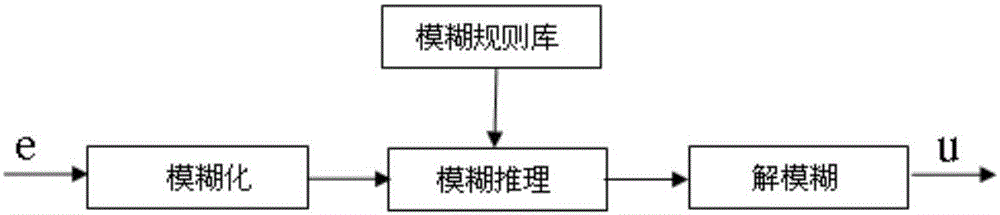

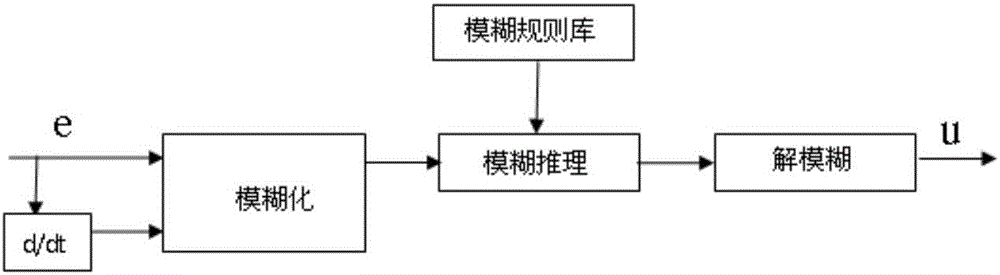

[0039] Such as figure 2As shown, the fuzzy calculation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com