Accurately positioned and automatically packaged sample collector

A technology of precise positioning and sample collector, applied in the direction of sampling device, etc., can solve the problems of misalignment between the mouth of the sample barrel and the discharge flow pipe, inaccurate positioning of the sample barrel, difficulties in equipment manufacturing and installation, etc., and achieve the goal of eliminating human factors impact, simple and reliable workflow, and the effect of reducing water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to more fully explain the implementation of the present invention, implementation examples of the present invention are provided. These implementation examples are only illustrations of the present invention, and do not limit the scope of the present invention.

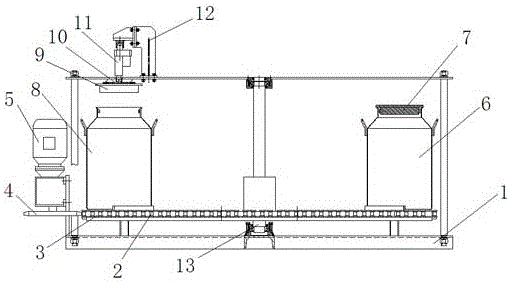

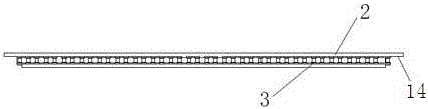

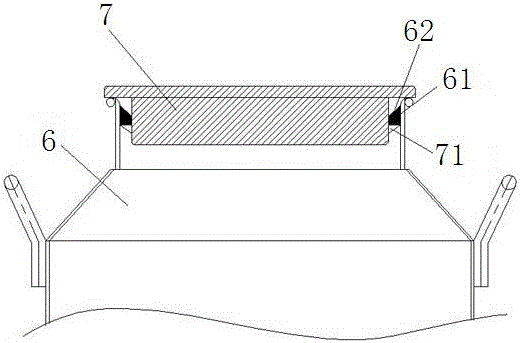

[0010] The present invention is further explained in detail in conjunction with the attached drawings. In the accompanying drawings, each mark is: 1: rack; 2: bottom plate; 3: chain; 4: sprocket; 5: motor; Limiting part; 62: Inclined surface; 7: Sample bucket one lid; 71: Lock bolt 8: Sample bucket two; 9: Sample bucket two lid; 10: Electromagnet; 11: Electric push rod; 12: Bracket; 13 : central rotation axis; 14: convex edge; as shown in the accompanying drawings, a precise positioning automatic packaging sample collector includes a sample collector frame 1 and a lower plate 2 for placing sample barrels, and the upper surface of the lower plate 2 is provided with Multiple sample barrel fixing positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com