Oil well temperature monitoring device

A monitoring device and oil well technology, applied in the field of temperature detection, can solve the problems of high processing cost, redundant insulation wrapping, poor derivation, etc., and achieve the effect of convenient maintenance and uncomplicated components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below by specific embodiment:

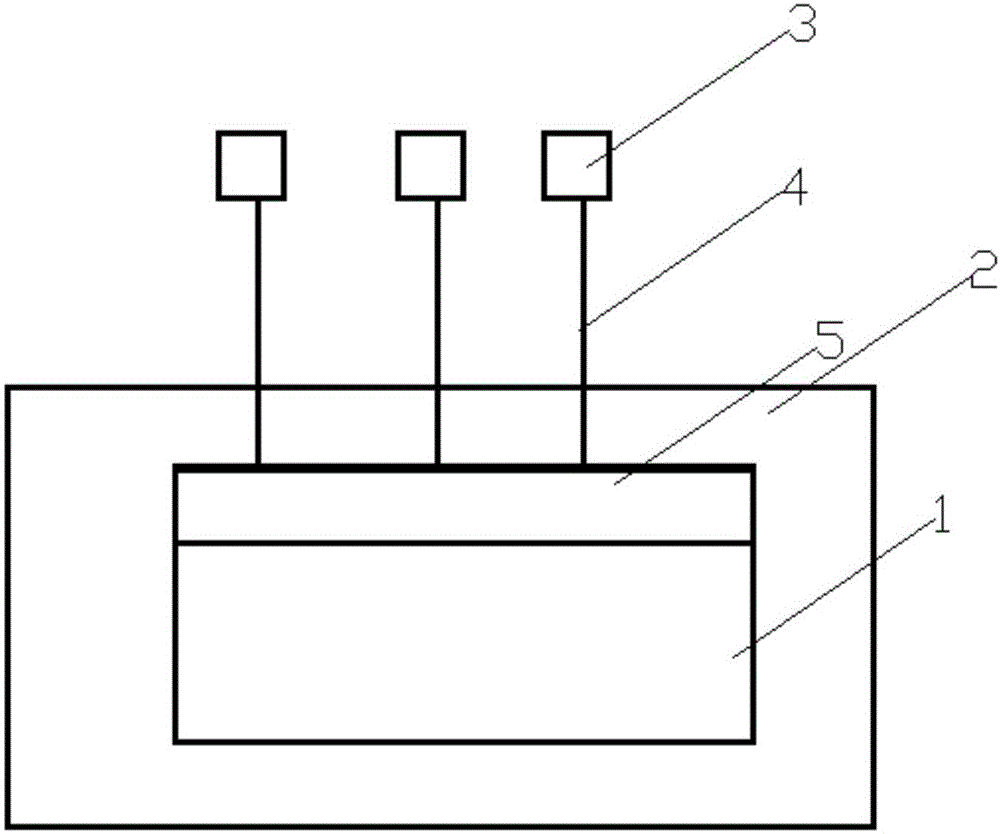

[0009] Such as figure 1 As shown, the oil well temperature monitoring device includes a bar-shaped module 1, the outer surface of the module 1 is attached with a transparent plastic cloth 2, and the transparent plastic cloth 2 protrudes from the main antennae 3 of the temperature sensing head and the temperature sensing head 4, The rear end of the temperature sensing head 4 extends into the opening groove 5 on the module 1 .

[0010] The working principle of the present invention is that the outer surface of the module 1 is attached with a transparent plastic cloth 2, and the transparent plastic cloth 2 protrudes from the main antennae 3 of the temperature sensing head and the temperature sensing head 4, and the rear end of the temperature sensing head 4 extends Inserted into the open slot 5 on the module 1, the components are uncomplicated and easy to maintain.

[0011] The above descript...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com