Wall plastering plane real-time monitor for building construction

A real-time monitoring instrument, construction technology, applied in measuring instruments, reference lines/planes/fans, instruments, etc., can solve problems such as laborious and time-consuming, difficult to learn, difficult for beginners to learn, etc., to achieve simple structure, safe and reliable structure, improve The effect of plastering efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

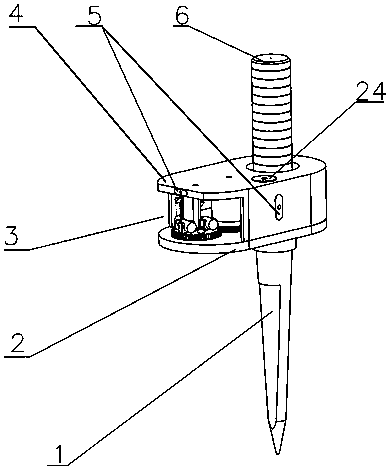

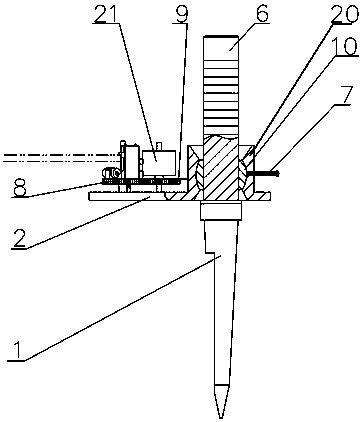

[0014] Such as figure 1 As shown, a real-time monitoring instrument for plastering a wall surface for building construction includes a top cover 4 and a base 2, and a window 3 is arranged on the top cover 4. Fig. 2 is a schematic diagram of the internal structure of the present invention after the top cover is removed. FIG. 3 is a top view of FIG. 2. Figure 4 is the left side view of Figure 2. Such as figure 2 , 3 , 4, the base 2 is provided with a drive gear turntable 9 and a toothed turntable 8, the drive gear turntable 9 and the toothed turntable 8 mesh and pivot relative to the base 2, the drive gear turntable 9 is driven by a micro motor 21, the micro The motor 21 is powered by a high-efficiency micro-battery 13, and is fixed on the base 2 with a micro-motor holder. On the toothed turntable 8, a green laser emitting tube 11, a red laser emitting tube 12, a vertical plate 17 and a button battery 22 are fixedly arranged. , the button battery 22 is electrically connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com