A separate microchannel low-temperature heat pipe heat exchanger and its application method

A technology of heat pipe heat exchanger and microchannel, which is applied in the field of separated microchannel low-temperature heat pipe heat exchanger, can solve the problems of high production and maintenance costs, unreasonable structural design, and low degree of automation, and achieve low production cost and structural design. Simple and reasonable, high degree of automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

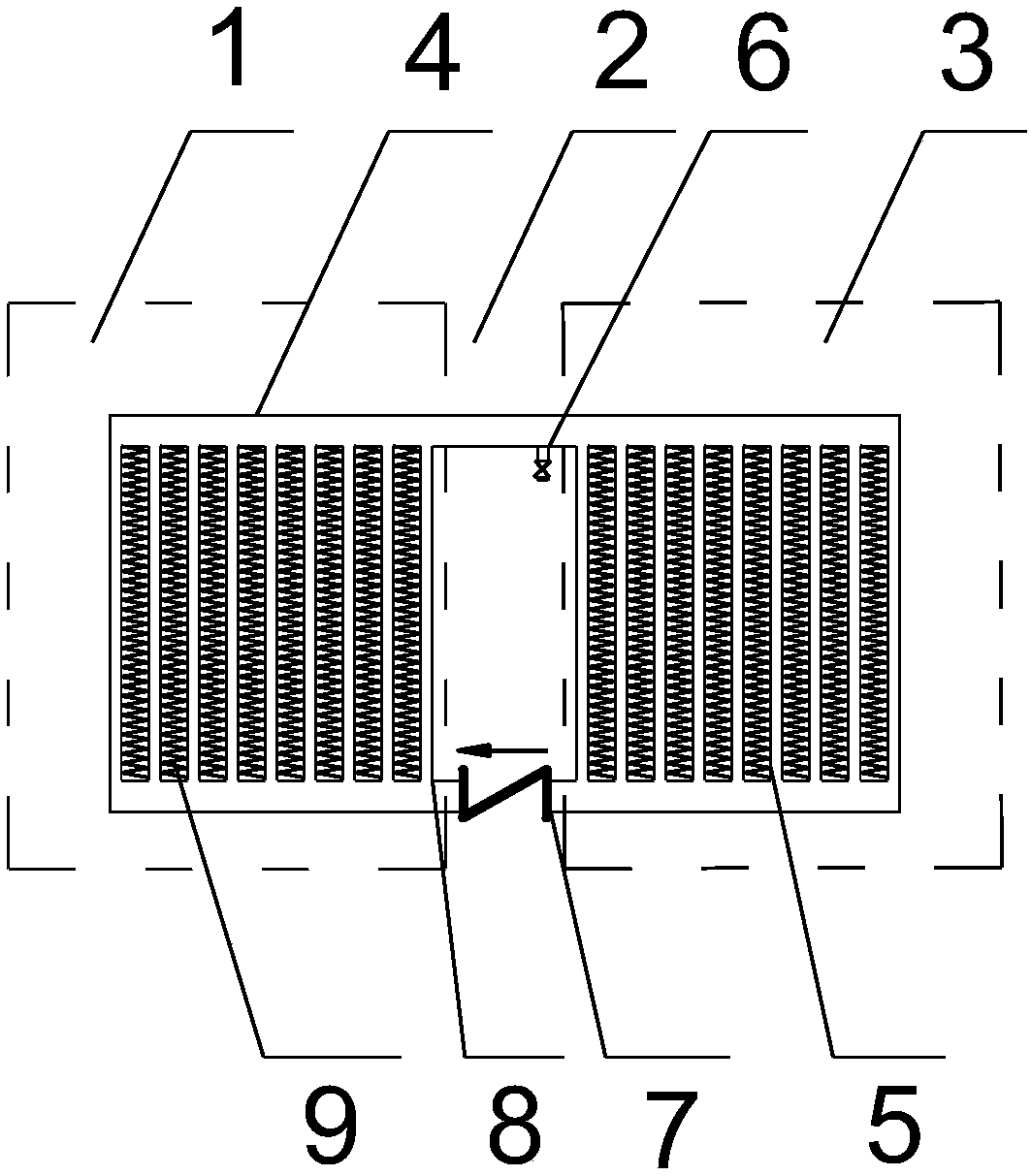

[0020] Attached below figure 1 A separate microchannel low-temperature heat pipe heat exchanger of the present invention and its application method are described in detail.

[0021] A separate microchannel low-temperature heat pipe heat exchanger, the heat exchanger includes an evaporation section 1, an intermediate section 2 and a condensation section 3, the intermediate section is located between the evaporation section and the condensation section; the evaporation section is connected to the main pipe 4 through the The condensing section is connected and forms an annular passage; the microchannel branch pipe 5 connected with the main pipe is arranged in the evaporating section and the condensing section; The main pipes are connected; the main pipes are also provided with a one-way check valve 7 . The middle section is also provided with a middle partition 8, and the inner wall of the branch pipe of the microchannel is also provided with fins 9. The main pipe includes an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com