Solar vacuum heat collecting pipe with double expansion joints

A technology of vacuum heat collecting tubes and expansion joints, which is applied in the field of heat collecting tubes of trough solar heat collectors and trough solar concentrators, can solve the problems of large heat absorbing parts, affecting life, and not easy to fix Reduce heat dissipation, improve utilization efficiency, and facilitate installation and fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

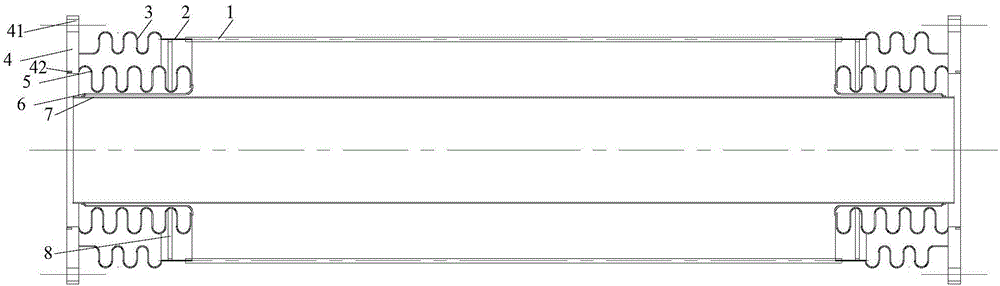

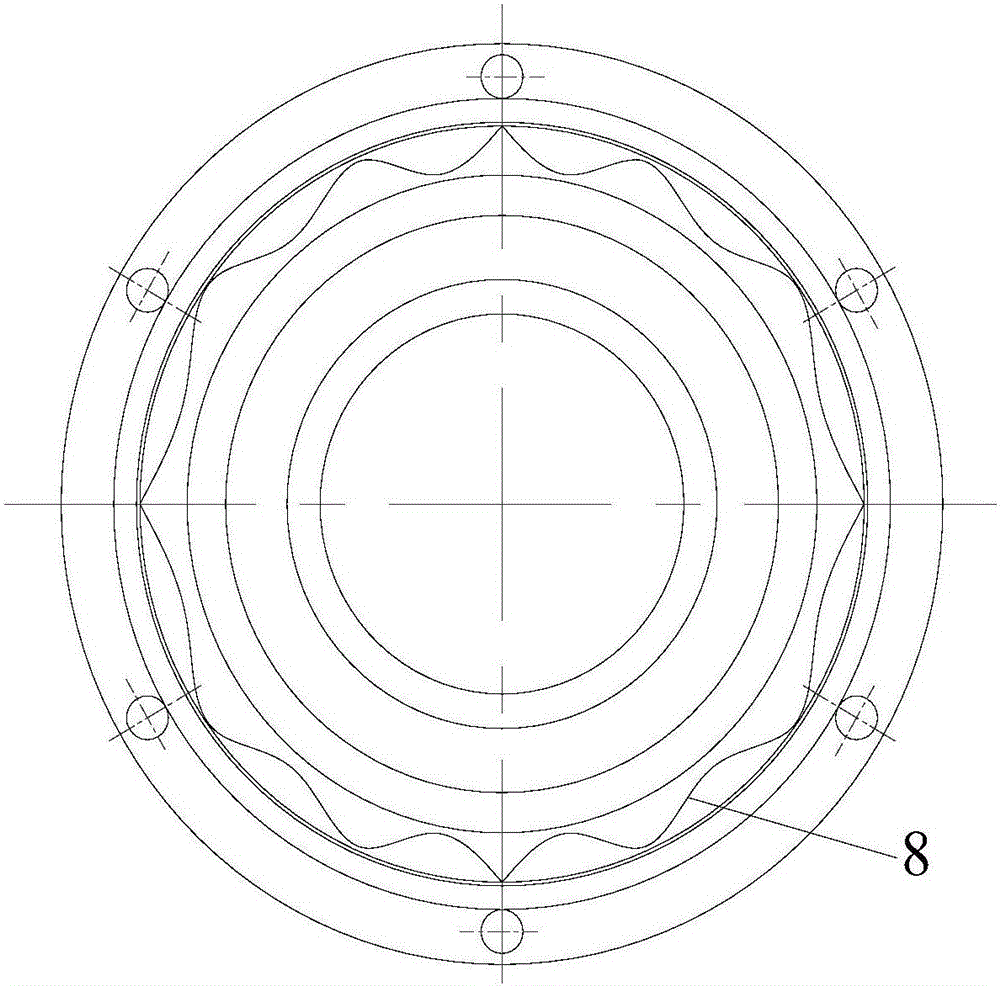

[0021] Such as figure 1 , 2 , 3 and 4 show a vacuum heat collector tube with grooved double expansion joints, including glass tube 1, Kovar tube 2, outer expansion joint 3, flange 4, inner expansion joint 5, support sleeve 6, suction Heat pipe 7, getter 8; the glass tube 1 and the Kovar tube 2 are connected by fusion sealing, the Kovar tube 2 and the external expansion joint 3 are connected by welding, and the external expansion joint 3 and the flange 4 are connected by welding Connection, the flange 4 and the inner expansion joint 5 are connected by welding, the inner expansion joint 5 and the support sleeve 6 are connected by welding, the support sleeve 6 and the heat absorption pipe 7 are connected by welding, and the getter 8 is placed in the vacuum tube.

[0022] The heat collecting tube adopts an outer expansion joint 3 and an inner expansion joint 5, and both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com